Considered one of the most critical roles in the PV system design and installation process, project management ensures the system delivery in the best desired timeline, quality, and budget. This role involves attention to details and coordination between different teams in terms of what steps to take next in the process. Project management tackles the methodology required for planning, scheduling, and managing resources including manpower and materials. In order for a project manager (PM) to be able to achieve that task, he/she should be qualified to prepare a plan that meets the requirements as specified in the contract with the PV system owners. The PM is usually a person who fully understand the technical aspects of PV projects, which include procurement, planning, scheduling, engineering, integration, and commissioning.

Project Development Phases

Electric solar projects go through certain stages to be fully completed. This includes the following phases:

- Project initiation

- Project planning and design

- Project installation

- Project monitoring

- Project completion

These stages can vary according to the system, type, and size. That will be discussed in the considerations later on this page.

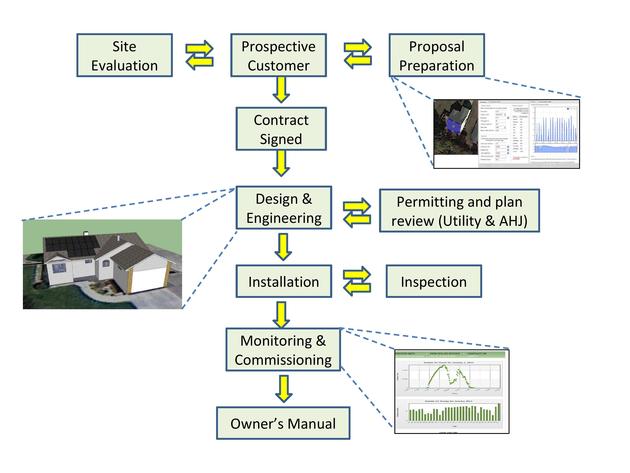

Figure 10.1 illustrates an example of the workflow for a small residential/commercial PV system. The complete PV system process usually follows this order: prospective customer, site evaluation, proposal preparation, contract signed, design and engineering, permitting and plan review (utility and AHJ), installation, inspection, monitoring and commissioning, owner's manual.

The work starts once a new customer shows interest in installing a PV system. A team of analysts begins preparing a simple drawing and some calculations to estimate the size of the solar system and to prepare a proposal. Most utilities rely on “PVWatt,” the free online solar database and simulation tool published by The National Renewable Energy Laboratory (NREL), to predict the annual solar energy production for the site (as we learned in previous lessons). As can be seen, NREL tools give the user options to find potential locations for the solar systems and to estimate the size of the system without going to the actual site.

Once the proposal is generated and discussed with the customer, the company representative will conduct a brief survey to gather more information about the site, which is required in order to start the preliminary engineering design. Then, the project will be entered into the pipeline of projects, and it will be directed to the engineering department for a preliminary design. The role of project management is to oversee all the design and engineering progress on each potential PV system and then ensure the right coordination between the internal departments.

The first step in the design is to generate the three-dimensional model that matches the actual site dimensions. This preliminary design will then be sent back to the customer for any feedback or changes that he/she sees are essential for the PV system in terms of location selection, aesthetics, and finances. Once the customer approves the preliminary design and he/she signs the contract, the engineering team will finalize the structural and electrical diagrams and required calculations after a followup visit for final site evaluation, where more detailed information is gathered. These designs will be reviewed by other engineers to ensure design adherence to local and national engineering codes (NEC article 690 and any other local AHJ), as we discussed earlier. In some cases, the designs need to be reviewed by a third party, such as an independent engineering firm, and then sent to the utility and AHJ for permitting and interconnection. Upon acceptance of the design by the utility engineering department, the project will enter the last stage in the engineering department, which is construction documents preparation and installation.

The project manager should also pay attention to the review timeline for the permit to be issued. In some places, the utility review process may require a couple of months, depending on the workload and number of PV projects submitted.

Simultaneously, the project manager should coordinate with the procurement team to ensure system component availability and when these materials should be delivered to the site to be installed by the PV installers at a prescheduled time agreed upon by the customer. As can be seen, logistics coordination is essential for optimal performance of the teams and to guarantee timely delivery of the system.

The system can also be monitored remotely to ensure the real system meets production expectations through the Internet profile of this particular system, as illustrated in Figure 10.1. The system can also be monitored for any technical problems within the operation that may appear during the entire lifespan of the system.

Once the system is up and running, the solar firm usually provides the customer with an owner’s manual to ensure that the customer has enough basic information about the system (for small systems such as rooftop PV, the installer can prepare the manual).

Considerations

Construction strategy depends highly on system type, size, and mounting structure used. When the project manager is preparing for different system requirements, he/she should consider various strategies to accomplish the design goal while meeting the construction timeline.

Ground mount systems:

As we discussed previously, this system mounting structure requires land space, and depending on the system size, land preparation, such as leveling and base preparation, which could raise a challenge to the PV system. In this case, the project manager should consider a thorough site evaluation of the land requirements before going forward with the scheduling of the delivery time of components and installation dates.

Pole mount system:

We remember from previous lessons that this mounting type requires less land space. However, in some cases, digging a hole in the ground may require detailed information about the type of sand and rocks in that area to prepare installers for the size of work needed and also to ensure delivery of the correct excavation equipment for earthwork.

Roof mount system:

Whether it is a simple residential or complex commercial roof mount system, any installation on the roof requires special attention to the roof age, allowable structure load, and installers' skills. The main concern for roof mount systems is leakage and liability.