Solar Photovoltaics

When most people think of “solar power,” they think about one of two things – vast arrays of solar collectors laid out in hot deserts (the left-hand panel below) or smaller arrays on rooftops or highways (the right-hand panel below). This is perhaps the most ubiquitous method of converting solar energy into electricity, but it is not the only method. These arrays of solar collectors are known as “solar photovoltaic” installations or Solar PV for short.

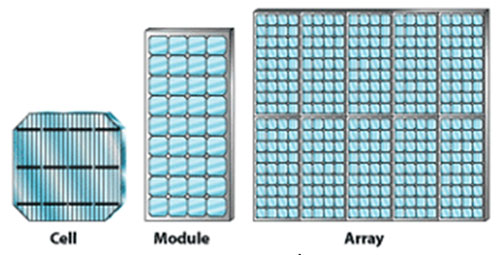

Solar PV installations consist of individual collectors called cells, which are packaged together in bundled modules. An individual cell does not generate enough electricity to power much of anything, which is why they must be bundled together. A single module might be enough to provide electricity for a single parking meter or roadside telephone. A number of modules can be further bundled together to form an array (see below). Multiple arrays might be needed to provide electricity for a building or a house.

There are many different kinds of solar PV cells in existence (and even more being developed in research laboratories), but they all work in more or less the same way. Unlike virtually any other type of power plant (be it coal, natural gas or wind), there is no turbine in a Solar PV cell. In fact, there are basically no moving parts at all. .

Solar PV cells harvest solar energy through a phenomenon called the photovoltaic effect, discovered in 1839 by the French physicist Bequerel. Photons of solar energy interact with electrons to “excite” them, causing them to move through conductors, thus producing an electric current. The first solar PV module was made at Bell Labs in the 1950s, but was too expensive to be more than a curiosity; in the 1960’s NASA started to use PV modules in spacecraft and by the 1970s, people started to explore their use in a wider range of terrestrial applications.

This following video explains a bit more about how Solar PV cells work and describes the different Solar PV technologies in use today. One of the potentially most important evolutions in Solar PV technology is the use of semiconducting materials other than silicon in Solar PV cells. These materials are of interest because they could, in concept, allow more of the sun’s energy to be captured on a single array. But they face barriers in the form of high costs and, in some cases, questions about the availability of raw materials.

Video: Photovoltics, a Diverse Technology (4:26)

PRESENTER: 30 years ago, the first solar cells were made of silicon. And today, silicon makes up more than 3/4 of the rapidly growing worldwide photovoltaic market. But photovoltaic, or PV cells, are also made with other semiconductor materials. Why so many types of solar cells? This diversity is due to innovation. PV materials are improving. Manufacturing costs are dropping. And PV applications are expanding. Balancing these three factors can meet demands for clean, green power, while creating more American jobs.

Innovation means improving photovoltaic materials. Every PV material absorbs sunlight differently, depending on bandgap, which is a unique electronic property of the material. Some cells absorb sunlight within the first micron of material. Others need 100 times more material to absorb the same amount of energy from the sun.

The sun's energy arrives as a combined spectrum of different wavelengths. Each color carries a different amount of energy. This make solar cell design more complex.

If the energy of the absorbed photon matches the PV materials bandgap, then an electron-hole pair is created. If the photon has more energy, it still creates only one electron-hole pair, but the additional energy is lost as heat. If the photon has less energy than the bandgap, it is not absorbed.

Low bandgap materials absorb most of the solar spectrum, creating many electron-hole pairs, producing a high current. However, PV cells with low bandgap materials have a low voltage. High bandgap materials absorb only higher energy photons, creating fewer electron-hole pairs, producing a lower current with a higher voltage.

A solar cell's efficiency is the percentage of the solar energy shining on the cell, that is converted into electrical energy. One way to increase efficiency is to use multiple layers, to capture power from multiple wavelengths of light. Understanding the properties of each PV material, allows scientists to improve designs that maximize the power of the cell.

Innovation in PV also means lowering the cost of manufacturing. Crystalline silicon cells have high efficiency, because they used very pure single-crystalline silicon, which is expensive to manufacture. Multi-crystalline silicon cells have lower efficiency, but they can be cheaper to manufacture, because they use lower quality silicon, less energy, and simpler manufacturing equipment.

Thin-film solar cells can be made for material such as-- cadmium telluride, copper indium diselenide, or amorphous silicon. These materials absorb light more readily than crystalline silicon, so they can be used in very thin layers that are less expensive to produce. Thin-film solar cells are generally less efficient than crystalline silicon cells, but they can be cheaper to manufacture because they use less semiconductor materials, which are grown on glass or flexible foil.

Finally, innovation means meeting different applications best suited by different types of solar cells. Today, PV devices produce power to meet the needs of utilities, businesses, homes, and consumer products.

Large-scale installations can use a range of highly reliable PV technologies. Solar powered satellites are more sensitive to power per pound. These high-efficiency solar devices can accept higher material and manufacturing costs to get more electricity from less material. Flexible thin-film devices are being installed in innovative ways, including incorporation into structures with complex shapes.

Photovoltaics are here now. And the diversity of PV devices is advancing as scientists improve PV materials and develop new manufacturing methods. More solar applications are emerging, as these innovations make PV more affordable.

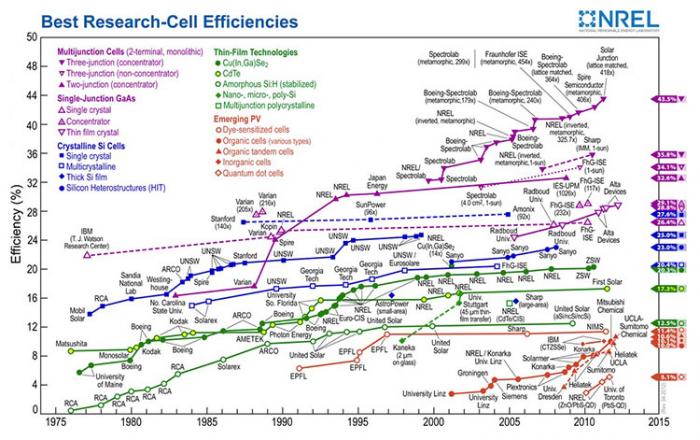

Most modern Solar PV technologies are relatively inefficient compared to other forms of electricity generation. Remember here that “efficiency” refers to how much of the fuel that is injected into an electricity generation system is actually converted into useful electricity, versus being rejected as waste heat or otherwise escaping from the generation system. While modern coal-fired and gas-fired power plants can have efficiencies as high as 60% (or sometimes even higher), most Solar PV cells convert sunlight to electricity with an efficiency of 20% or less (see below), though this number has been rising over time.

Whether the efficiency of Solar PV cells is all that important is a matter of some debate. On the one hand, higher-efficiency cells would require less land or space to produce a given amount of electricity. Land use (or the number of rooftops) can be a significant limiting factor in the deployment of Solar PV. On the other hand, fuel from the sun is free and there is no scarcity of sunlight, so whether Solar PV cells can achieve 30% efficiency versus 20% efficiency may not be such a big deal, and may not be worth the extra economic cost to produce such high-efficiency cells.