Solar dryers are predominantly used in agricultural industry to dry foods for storage purposes. There are direct and indirect types of solar dryers.

The direct drying systems expose the product to the direct sunlight. The key processes here are heat transfer from the heating source to the target product and mass transfer of moisture from the product to the air. In these systems, the drying process is sometimes assisted by air flow, which helps to transport moisture convectively.

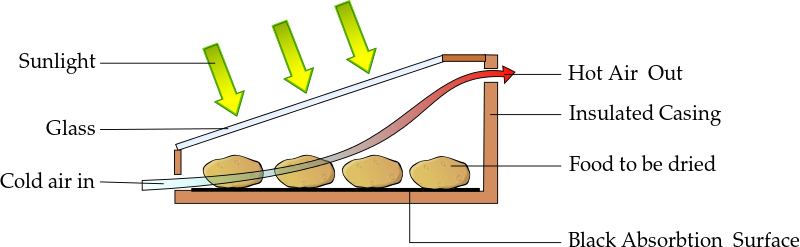

Indirect dryers use absorbing surfaces, which heat the air, which is further passed over the target product. So there is no direct contact of the solar radiation with the product in this design. In indirect systems, it is easier to protect the agricultural product from external damage (weather, birds, insects, direct radiation).

The main idea of dryer system is to supply more heat to the process than would be available under ambient exposure and also to improve moisture migration via active or passive design.

Active and passive solar energy dryer designs are overviewed in the following reading source:

Reading assignment

Kalogirou, S.A., Solar Energy Engineering, Chapter 7. Section 7.4. Solar Dryers. (7 pages)

This book is available online through the Penn State Library system.

Supplemental Reading on Solar Drying

Belessiotis, V. and Delyannis, E., Solar Drying, Solar Energy 85 (2011), 1665-1691.