Solar desalination is an elegant combo since the solar heat, which in arid areas creates problems with fresh water shortages, is used to counter-act the problem. This idea has been under development and implementation in zones which will probably have to rely on desalination of seawater to meet their potable water needs, such as California, Israel, Arabian Peninsula, and some others.

One of the processes that can be used for desalination is water distillation. It is one of the oldest approaches when thermal energy is used to evaporate water from a saline solution and condense it in a separate collector. What is left behind is more concentrated brine solution or in case of complete evaporation? Solid salt. This process has been used for millennia for production of salt fromseawaterr. There are salt production facilities around the world that still use the same salt production techniques that were developed hundreds of years ago. The earliest use of solar distillation for obtaining fresh water is attributed to Aristotle (4th Century BC).

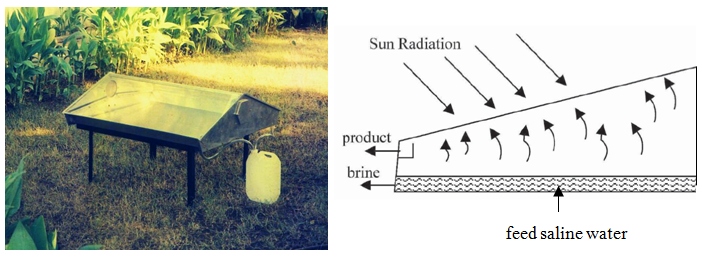

Example of a small scale self-made system is given in the figure below. In this design, black-backed water basin is absorbing solar radiation, and the evaporating water is condensed on the tilted dome or roof, further dripping down to the channel and directed for collection. This is the same process that is used by nature to power the evaporation/condensation/rain/stream cycle, but in a contained and controlledenvironment.

While on the topic of the history of solar desalination, during World War II, the use of a portable solar still that was included in U.S. Air Force and Navy emergency kits saved many lives in the South Pacific. When airmen and seamen were stranded at sea for extended periods of time, survival was possible through the production of clean drinking water by a solar driven desalination process.

Today, there are many solar thermal desalination water production facilities around the world of much larger scale, but based on the same physical principles. Those may use direct sunlight or standard collector technologies to provide heat for the extracting of clean water from seawater or brackish water.

Learn more about solar distillation and evaporation processes in the following reading:

Reading assignment

Kalogirou, S.A., Solar Energy Engineering, Elsevier 2009. Chapter 8, Sections 8.1 and 8.3. (12 pages).

This book is available online via Penn State library system

Distillation vs. Reverse Osmosis

Distillation is much cleaner process compared to the reverse osmosis technique used by many contemporary desalination plants. In this technology, water is pushed through the semipermeable membrane, which separates out the ions, macromolecules, particles, and other contaminants contained in water. One of the cons of this method is the need for pressurization, which is commonly achieved by applying conventional energy sources (electric high-pressure pumps, etc). Hence this technology is a potential contributor to carbon emissions if fossil fuels are used in powering the process. Its energy efficiency has been improving, so it is still the most widespread method of commercial desalination. Recent reports boast 3 kWh/m3 of processed water as energy rate. Another disadvantage of the reverse osmosis is waste water production. Not all water entering the system passes through the membrane - 15 to 85% (depending on the operating pressure) of it is rejected and sent to the wastewater stream. The necessity to dispose off the wastewater containing increased amounts of salts and contaminants is an additional problem, which adds to the cost and complexity of operation.

Passive vs. Active Solar Desalination

The passive methods of solar desalination do not use any heat collectors, but rather use the direct sunlight for evaporating the input water. Although this creates a limitation on the system efficiency and rate of fresh water production, the simplicity of design makes passive devices applicable at the field conditions at different scales (e.g WaterconeTM or CarocellTM products etc.).

The active methods employ flat-plate, CPC, or parabolic trough collectors to provide higher temperature heat and enable faster distillation process. One of the examples is Aqua4 technology designed by WaterFX with the purpose of reclaiming process water and make businesses and communities less dependent on imported fresh water. The technology is modular, and each module combines a parabolic trough collector and steam-heated evaporator, which is able to produce fresh water with 90% efficiency as well as recover solid salt components.

You can learn more about this project from the video and WaterFX website:

1

PRESENTER: For our customers to be able to control their own water resources. So we're developing tools and technology here at the aquifer demonstration plant that will enable large uses of water to actually reclaim their own fresh water, rather than depending on the outside delivery of water to them. We've partnered with the Panoche Water and Drainage District, as the Panoche Water District has done a lot of work to look at different drainage reuse scenarios.

They've tested a number of different technologies. They've designated land as a drainage region. They are even looking at growing salt tolerant crops, things like Jose tall wheat grass that actually can handle higher levels of salinity So we're amongst a very progressive water district, that is sort of leading the charge in developing new solutions.

The challenge is finding an outlet for the drainage water. We've reached the point where local water resources, especially in water scarce regions like California, are no longer suitable. The quality has declined over time, because there are a lot of natural minerals and natural salts in the ground. That drainage water can range in salinity from a couple of thousand parts per million, all the way up to 15,000 parts per million-- which is about half the salinity of seawater. And because the drainage water has that level of salts that's not suitable for discharge to the river systems, because it affects the natural wildlife.

The primary objective is we want to recover freshwater, and use that freshwater for agricultural purposes, for potable consumption, for any use of fresh water that you can think of. But the secondary objective is that we actually want to concentrate the salts and recover the valuable components. And so what we're doing here at this particular demonstration project, is we're going to recover that drainage water, and treat it so that it can be reused as fresh water and we can actually remove the salts. In the salts themselves, there's chemicals, there's metals, there's fertilizer, and there's components that can be used for building products. So there's a number of things in there that can actually generate revenue. The water that we produce here is the highest quality fresh water. It's pure H2O, and so it can be used for any fresh water purposes.

The Aqua4 technology involves four distinct steps. The first stage is to collect solar radiation in a concentrated solar collector. We use that energy to generate heat and deliver the heat through a mineral oil to the second stage, which is a multi-effect evaporator.

In the evaporator, we basically generate steam from the heat, and we use that steam to condense and recover fresh water. And then the steam is efficiently used in three separate effects to generate the product water. The third stage is a heat pump, where we efficiently recover waste steam to increase the productivity. And the fourth stage is a thermal storage system, where we store excess heat, and we use that to run the plant 24 hours a day.

Aqua4 is a concentrated solar still. It's a device for capturing solar energy and using that energy to generate heat and evaporate and recover fresh water. The concept of a solar still is not new. It's a technology that's been around for literally hundreds of years. But what we've done here is we've made it quite a bit more efficient, and we've accelerated the rate of evaporation by a factor of about 30. So whereas with natural solar energy you would require, let's say, an area of 30 acres to evaporate a given volume of water, with this particular technology, we can do the same rate of evaporation in 1 acre.

The design of the system is such that we wanted it to be highly modular and highly scalable. So we want the same system to be usable for very small applications all the way up to very large scales. So the way it's been designed, a single module takes up about 6,500 square feet and at commercial scale will produce about 65,000 gallons per day of fresh water or treat 65,000 gallons per day. So that boils down to about 10 gallons per square foot per day. And that basic number can be used to scale this system up really to any size.

Every year, water availability has become tighter. And so this year as an example, the water districts in this particular area only received about 20% of the water that they're allocated. And so when the availability of water goes down, the cost obviously goes up because they have to scramble to find alternative sources. And that does affect food prices. It affects economic activity in the state. It affects agricultural jobs. And so we think that this is one potential solution to alleviate the dependency on imported water and instead put the control over water resources back in the hands of the businesses that utilize water.

The systems such as the one demonstrated in the video are classified among the indirect systems because there is not direct exposure of the input water to the sunlight. Instead the solar heat is absorbed by a solar collector and further used to run a disalination process. Learn more about the indirect desalination processes in the following reading:

Reading Assignment

Kalogirou, S.A., Solar Energy Engineering, Elsevier 2009. Chapter 8, Section 8.4 Indirect Collection Systems. (12 pages).

This book is available online via Penn State library system.

Solar Moisture Extraction

There are relatively new methods being developed at the research level that use liquid desiccants to extract water from air. This does not exactly fall within the desalination field, but pursues the same purpose - providing potable water. Liquid desiccants, such as brine solutions (e.g. LiCl) are used to absorb moisture from air; then solar heat is used to regenerate the desiccant by evaporating water, which is collected as condensate. This technology is even applicable in very hot and dry climates (deserts). Source: Science Daily