4.5. Types of PV technology and recent innovations

There are different types of photovoltaics, some developed long ago, and others that are relatively new. Descriptions below provide a brief overview of a few well-developed PV materials. As you read through, please also open the links within each paragraph to get more information about each technology.

Monocrystalline silicon

Monocrystalline silicon solar cells are probably the oldest type of solar cells. They are made from pure silicon crystal, which has continuous lattice and almost no defects. Its properties provide for high efficiency of light conversion (typical ~15%; recent developments by SunPower boast improved efficiencies up to 22-24% ). Manufacturing of the Si crystals is rather complicated, which is responsible for high cost of this type of photovoltaics. Recent developments have decreased the total thickness of Si material used in monocrystalline cells to reduce cost. The monocrystalline silicon cells have a typical black or iridescent blue color. The monocrystalline silicon cells are believed to be very durable and last over 25 years. However, their efficiency will gradually decrease (about 0.5% per year), so replacement of operating modules might be needed sooner. The main disadvantages of the monocrystalline silicon panels are high initial cost and mechanical vulnerability (brittle). (Solar Facts and Advice: Monocrystalline Silicon, 2013)

Polycrystalline (or multicrystalline) silicon

Polycrystalline cells are made by assembling multiple grains and plates of silicon crystals into thin wafers. Smaller pieces of silicon are easier and cheaper to produce, so the manufacturing cost of this type of PV is less than that of monocrystalline silicon cells. The polycrystalline cells are slightly less efficient (~12%). These cells can be recognized by their mosaic-like appearance. Polycrystalline cells are also very durable and may have a service life of more than 25 years. The cons of this type of PV technology are mechanical brittleness and not very high efficiency of conversion. (Solar Facts and Advice: Polycrystalline, 2013)

Amorphous silicon (Thin-film)

Thin film photovoltaic cells are produced by depositing silicon film onto substrate glass. In this process, less silicon is used for manufacturing compared to mono- or polycrystalline cells, but this economy comes at the expense of conversion efficiency. Thin-film PV have efficiency of ~6% versus ~15% for single crystal Si cells. One way to improve the cell efficiency is to create a layered structure of several cells. The main advantage of the thin-film PV technology is that the amorphous silicon can be deposited on a variety of substrates, which can be made flexible and come in different shapes and therefore can be used in many applications. The amorphous silicon is also less prone to overheating, which usually decreases the solar cell performance. Amorphous silicon is most developed among the thin-film PV. (Solar Facts and Advice: Thin Film, 2013)

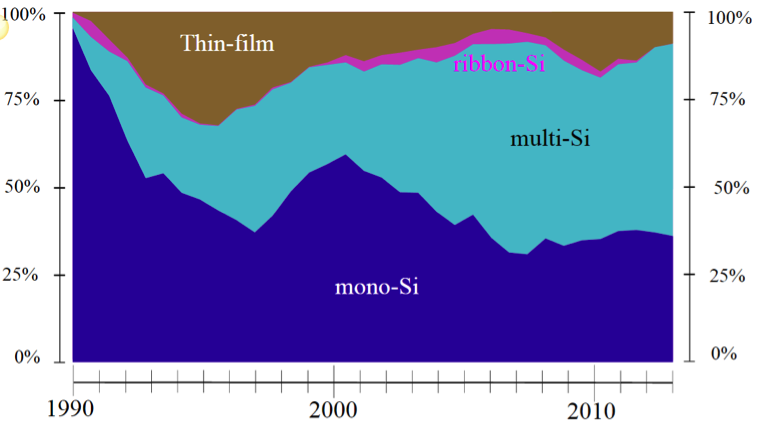

Figure 4.9, below, shows the trend of development and commercial implementation of different types of silicon PV technologies. There is no clear domination of a specific type of silicon substrate, as they all present a trade-off between cost and efficiency.

Cadmium Telluride, CdTe (thin-film)

CdTe PV are another kind of thin-film solar technology. It has become quite popular due to the lower cost per kW-hour. The best efficiency obtained with CdTe cells is around 16%. One of the advantages of the CdTe cells is that they capture shorter wavelengths of light than silicon cells can do. There are some environmental concerns related to the limited supply of tellurium and potential toxic impact of cadmium at the stage of CdTe panel disposal. Developing effective closed-loop recycling technologies can be a game-changing factor in favor of this technology. (Solar Facts and Advice: Cadmium Telluride, 2013)

Copper Indium Gallium Selenide (CIGS)

CIGS PV have become a popular new material for solar cells, as it does not contain toxic Cd, and has higher efficiency (just under 20%). At this moment, the CIGS are the most efficient among the thin-film PV technologies. While lab results confirmed high promise of this kind of photovoltaics, the mass production of CIGS proved to be a problem. The CIGS cells are manufactured by thin film deposition on a substrate, which can also be flexible (unlike the silicon cells). Similar to CdTe cells, the CIGS cells demonstrate good resistance to heating.

Polymer and organic PV

Organic materials are quite attractive since they can be involved in high-output manufacturing and also because they can be made in various thicknesses and shapes. These types of cells are relatively lightweight (compared to silicon cells). Also, they offer flexibility and relatively low fabrication cost. They, however, are much less efficient (about 1/3 of a typical Si cell efficiency) and sometimes prone to quicker degradation (shorter service life). More technical details about this type of PV technology can be read in this Wikipedia article: Organic Solar Cell.

These are a few most well-known varieties of PV technology, but there are many more innovations that are at the research and development stage. Breakthrough in new materials and cell design may be responsible for the growth of the PV industry in the upcoming decades. For this lesson discussion forum, you will be asked to do a search of recent innovations and share a quick synopsis of one that you believe especially interesting.