Conversion of Heavy Gas Oil

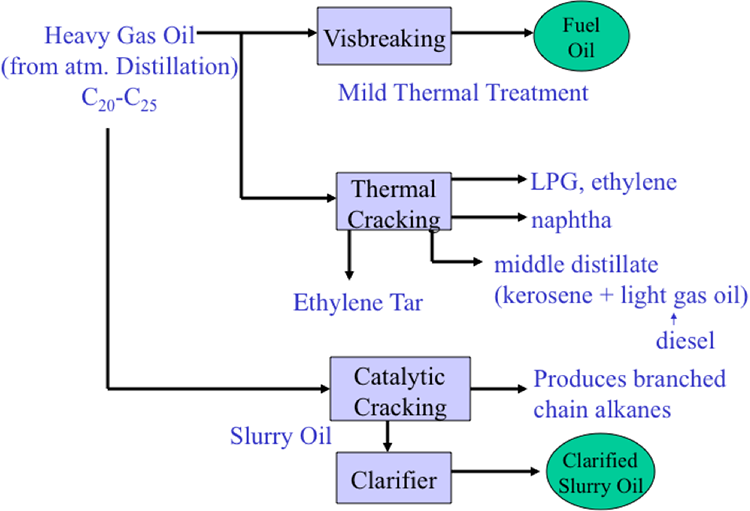

Moving down to the side streams of the distillation column, heavy gas oil constitutes the next fraction in line. Some generic conversion processes for the heavy distillates, such as heavy gas oil (consisting of C20 to C25 hydrocarbons), are shown in Figure 3.5. These processes, aimed at reducing the molecular size or the boiling point of gas oil compounds, involve thermal cracking or catalytic cracking. A mild thermal cracking process, called visbreaking, is applied to reduce the viscosity of the feedstock, and it is more frequently applied to residual fractions, such as vacuum distillation residue. A more severe thermal cracking of heavy gas oil can be used to produce LPG and ethylene and light and middle distillates from heavy gas oil. A highly aromatic byproduct from thermal cracking is called ethylene tar. Ethylene is an important petrochemical feedstock, while ethylene tar can be used as feedstock to produce carbon blacks. Catalytic cracking is more frequently used for conversion of heavy gas oil to gasoline.

Products and processes of heavy Gas Oil Conversion

Start: Heavy Gas Oil (from atm Distillation) > 20 – 25 Carbons goes to

- Visbreaking (mild thermal treatment)

- Fuel oil

- Thermal Cracking

- LPG, ethylene

- Naphtha

- Middle distillate (kerosene +light gas oil)

- Ethylene Tar

- Catalytic Cracking

- Produces branched chain alkanes

- Slurry Oil

- clarified

- Clarified slurry oil

- clarified

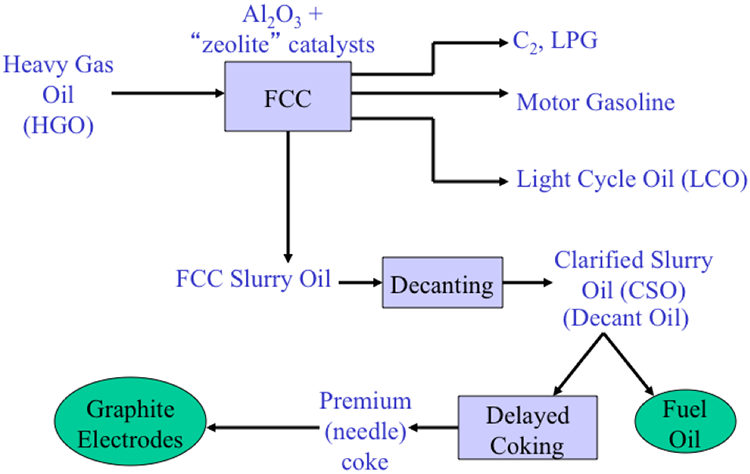

A particular process of catalytic cracking, Fluid Catalytic Cracking, is almost exclusively used worldwide in heavy gas oil and light vacuum gas oil conversion. This process produces high octane gasoline primarily, with important byproducts, including LPG, light olefins and i-alkanes, light cycle oil (LCO), heavy cycle oil (HCO), and clarified slurry oil (also called decant oil), as shown in Figure 3.6. LCO is used in the U.S. to produce diesel oil by hydrocracking, and decant oil can be used as fuel oil, feedstock for carbon black manufacturing, and to produce a special type of petroleum coke called needle coke. Needle coke has a microstructure that makes it a good precursor to graphite electrodes that are used in electric-arc furnaces to recycle scrap iron and steel. The manufacturing of graphite electrodes, using a byproduct from FCC used to produce gasoline, is considered a principal interface between petroleum refining and the iron and steel industry.

Products and Processes of FCC

Start: Heavy Gas Oil (HGO) goes to

- FCC with Al3O3 + Zeolite catalysis

- C2, LPG

- Motor Gasoline

- Light Cycle Oil (LCO)

- FCC Slurry Oil

- Decanting

- Clarified Slurry Oil (CSO/Decant Oil)

- Fuel Oil

- Delayed Coking

- Premium (needle) coke

- Graphite electrodes

- Premium (needle) coke

- Clarified Slurry Oil (CSO/Decant Oil)

- Decanting