Dewaxing

Another important separation process in petroleum refining is removal of wax. The process of dewaxing is introduced and discussed in the next subsection.

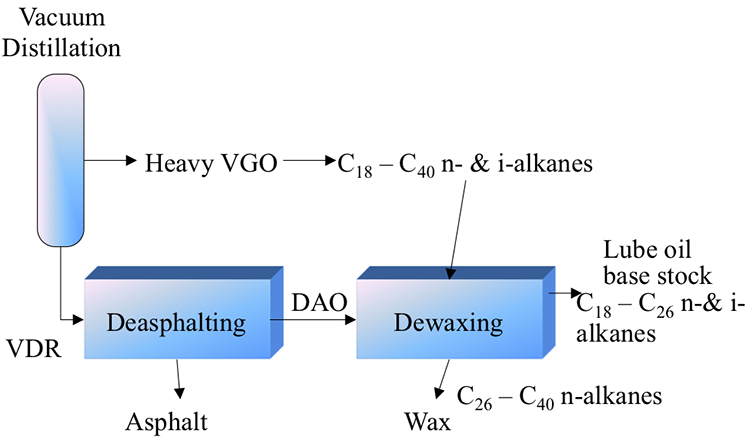

Figure 5.11 locates the dewaxing process in the refinery landscape. The feedstocks to dewaxing include DAO from deasphalting, and HVGO from vacuum distillation as shown in Figure 5.11 along with some compositional characteristics of the feedstock and the dewaxing product. Note that wax (long-chain paraffins) obtained in dewaxing is a marketable by-product. Lubricating oil base stock is the principal product of interest. The main purpose of dewaxing is to remove hydrocarbons that solidify readily (i.e., wax) for making lubricating oil base stock with low pour points (-9 to 14°F).

In addition to low pour points, other important properties of lube oil base stocks include:

- Volatility – should be low to keep oil in the liquid phase during engine operation. Vapors are not good lubricants.

- Viscosity– important to control because of lubrication and heat transfer considerations. Moderate viscosities are desired. Low viscosity may not provide the required lubrication and lead to high friction between metal parts. High viscosity causes loss of energy.

- Viscosity Index (change in viscosity with temperature) – small change in viscosity is desired over a wide temperature oil, i.e., high viscosity index (HVI). HVI ensures that the lube oil functions well at both cold start and at high temperatures generated by the engines.

- Thermal Stability – High thermal stability (or small degree of thermal degradation at high temperatures) is necessary to minimize viscosity loss and coke deposition on metal surfaces.

All of these properties depend on the molecular composition of the hydrocarbons constituting the lubricating oil base stocks. Commercial engine oils and other commercial lube oils are formulated with chemical additives that would enhance the performance of the base stocks.

Two commercial methods of dewaxing are:

- Solvent dewaxing - physical process; separation of wax by freezing and solvent transport.

- Catalytic dewaxing - chemical process; removal of wax by selective reaction of long chain n-alkanes (wax).