Natural Gas Processing

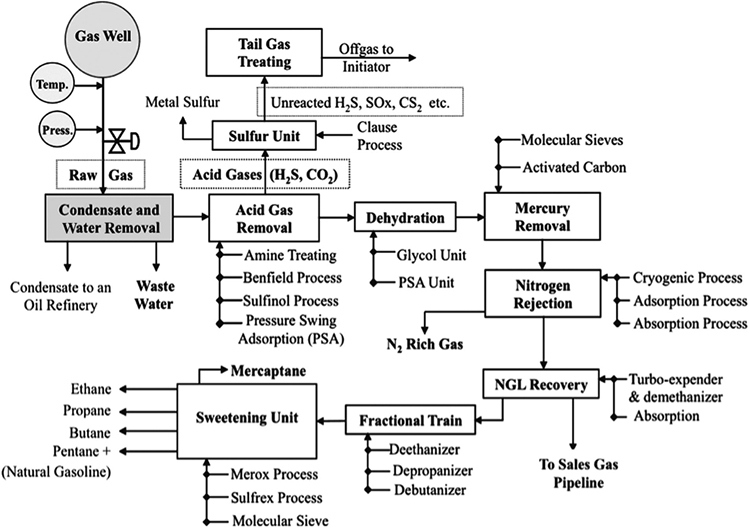

A comparison of Images 12.2 and 12.3 illustrates the significance of natural gas processing for purification of the raw natural gas to obtain a pipeline quality gas. In general, natural gas processing includes the following steps:

- Condensate and Water Removal

- Acid Gas Removal

- Dehydration – moisture removal

- Mercury Removal

- Nitrogen Rejection

- NGL Recovery, Separation, Fractionation, and Treatment of Natural Gas Liquids

In addition to these processes, it is often necessary to install scrubbers and heaters at or near the wellhead. The scrubbers remove sand and other large-particle impurities. The heaters ensure that the temperature of the natural gas does not drop too low and form a hydrate with the water in the gas stream. Natural gas hydrates are crystalline ice-like solids or semi-solids that can impede the passage of natural gas through valves and pipes.

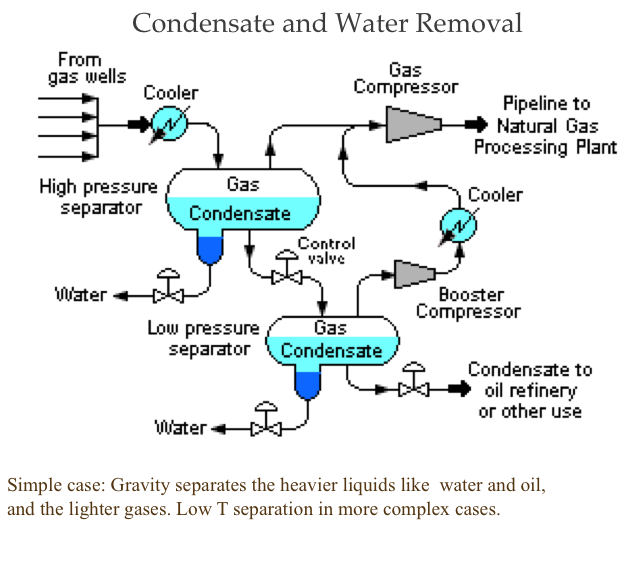

A generalized natural gas flow diagram is shown in Figure 12.2 [7]. After initial scrubbing to remove particles, the first step in natural gas processing is the removal of condensate (oil) and water that is achieved by controlling the temperature and pressure of the inlet stream from the well, as shown in Figure 12.4. Gas separated in this unit is sent to acid gas recovery; the condensate or the oil recovered is usually sent to a refinery for processing, while water is disposed, or treated as wastewater.

Acid gases (H2S and CO2) are separated usually by absorption in an amine solution, as discussed for H2S recovery in a petroleum refinery in Lesson 10. The recovered H2S is sent to a combined Claus-SCOT (Tail Gas Treating) unit to be converted to elemental sulfur, as was also discussed in Lesson 10. After removing the acid gases, the natural gas stream is sent to a dehydration unit to remove water typically by absorption in a glycol unit, followed by mercury removal (by adsorption on activated carbons or other sorbents), and nitrogen rejection either cryogenically, or by adsorption, or absorption depending on the nitrogen concentration. The last step in the processing sequence is the Natural Gas Liquids (NGL) extraction, fractionation, and treatment, as described in Figure 12.4.

Figure 12.4: Separation and Fractionation of Natural Gas Liquids [6]

Natural gas liquids (NGLs) have a higher value as separate products.

Two basic steps: 1) Extraction, 2) Fractionation

- NGL Extraction

Absorption Method- Similar to using absorption for dehydration, using a different absorbing oil for hydrocarbons.

- Dropping the temperature of the gas stream to around -120°F by expansion and external refrigeration

- Natural Gas Liquid Fractionation - works like Light Ends Unit

- Deethanizer - separates ethane from the NGL stream

- Depropanizer - separates propane.

- Debutanizer - boils off the butanes

- Butane Splitter or Deisobutanizer - separates iso and n-butanes.

NGL extraction can be carried out by absorption in oil that selectively absorbs hydrocarbons heavier than methane, or by a cryogenic expansion and external refrigeration to condense NGL.

Following the NGL extraction, the treated natural gas stream that is, now, mostly methane, or a gas compliant with the natural gas specifications is sent to the pipeline for transmission to the point of use. The extracted NGL, on the other hand, is sent to a fractionation unit that operates like Light Ends Unit in a refinery, as discussed in Lesson 5, separating ethane, propane, butane, and naphtha (>C5, natural gasoline). Note that the fractionation unit may also include a butane splitter or deisobutanizer to separate n-butane and iso-butane. You may remember from Lesson 8 that iso-butane is a feedstock to alkylation to produce high-octane gasoline when reacted with C3 and C4 olefins. NGL from highly sour gases may need additional treatment to remove mercaptans and other sulfur species before NGL leaves the processing plant.

[6. ]A. J. Kidnay and W. R. Parrish, Fundamentals of Natural Gas Processing, CRC Press, Boca Raton, FL, 2006, p.16.

[7.] M.R. Riazi, S. Eser, J. L. Peña Díez, and S. S. Agrawal, “Introduction” In Petroleum Refining and Natural Gas Processing, Editors: M. R. Riazi, S. Eser, J. L. Peña, S. S. Agrawal, ASTM International, West Conshohocken, PA, 2013, p.12.