Lessons

This is the course outline.

Lesson 1: Introduction to Petroleum Refining and Crude Oil Composition

Lesson 1 Overview

Lesson 1 Overview

Video: FSC 432 Lesson 1 (2:04)

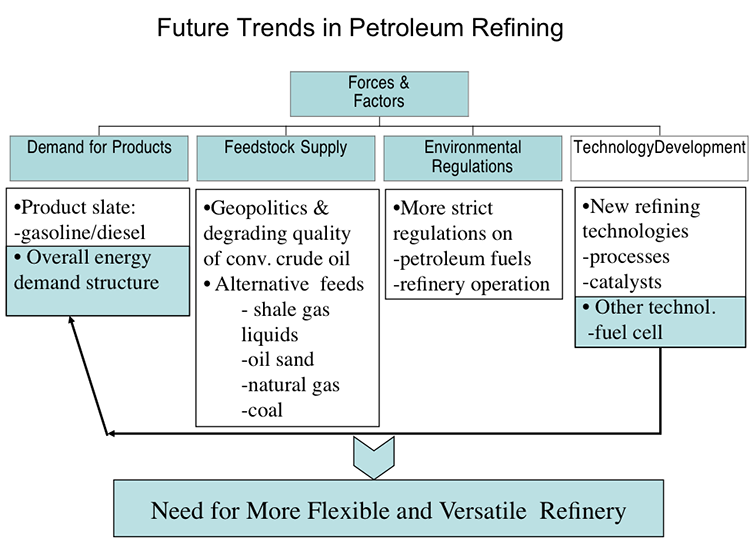

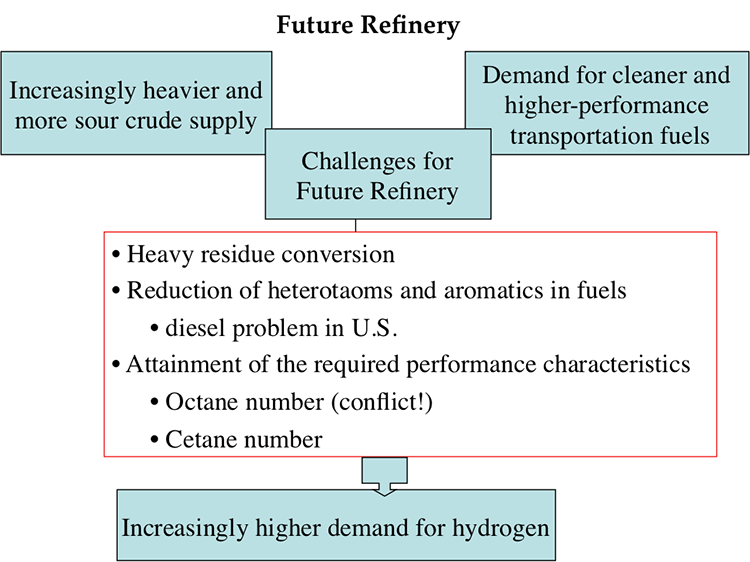

Hello. In this lesson, we will go over the market drivers for Petroleum Refining Industry, an overview of refinery processes and refinery products, and the chemical constitution of crude oil. Obviously, the principle driver for Petroleum Refining Industry is economics that is now very closely tied to environmental regulations as well. So we need to look into the supply and demand picture, whether it is for the crude oil or the refined products such as fuels, gasoline, diesel, jet fuel, et cetera, and the environmental regulations on the compositions of these fuels, as well as on the operation of the refinery, and the flexibility of the refinery to respond to the demand shifts or supply shifts on either side of this equation.

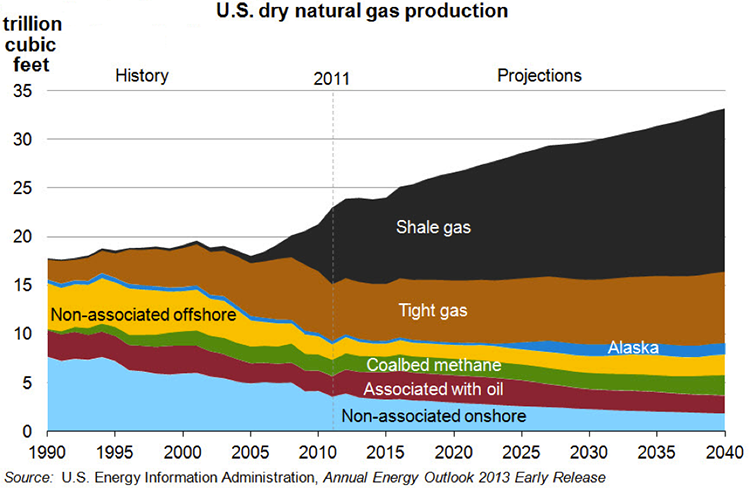

And we go over finally the chemical constitution of this very complex feedstock, crude oil, and how we can in essence better understand how different each crude oil is, and what our refiners can do to adjust the processes to accommodate these differences in the crude oil circle. A recent development in the United States increased production of shale gas, which also produces some liquid byproducts that are entering the refinery as alternative feedstock. We need to really understand how these feeds could be refined to give us a conventional set of products that we produce in the refinery. So I look forward to seeing you in these lessons and go through the activities.

Overview

Petroleum provides the largest fraction of primary energy supply in the U.S. and in the world [Figure 1.1,eia1]. Resource consumption patterns shown in Figure 1.1 reflect major epochs in human history, such as The Industrial Revolution, ushering in the rapid increase in coal consumption. Petroleum trace, for example, marks the mass production of automobiles with the introduction of Model T by Ford, world wars, supply crises of 1973 and 1979 and the economic recession in 2008. Transportation of people and goods in many parts of the world depends almost completely on petroleum fuels, such as gasoline, jet fuel, diesel fuel, and marine fuel. Apart from the fuels, materials that are necessary for operating the combustion engines of cars, trucks, planes, and trains also come from petroleum. These materials include lubricating oils (motor oils), greases, tires on the wheels of the vehicles, and asphalt to pave the roads for smooth rides in transportation vehicles. All petroleum fuels and many materials are produced by the processing of crude oil in petroleum refineries. Petroleum refineries also supply feedstock to the petrochemicals and chemical industry for producing all consumer goods from rubber and plastics (polymers) to cosmetics and medicine. Only ten percent of petroleum consumption, the portion that is not used for transportation or other energy outlets, is sufficient to manufacture all the materials used in human economy, with the exception of those derived from wood or minerals.

Figure 1.1 is showing the history of energy consumption of the U.S. and the source of the energy. For nearly the first 100 years, the U.S. used only wood as our energy source until about the mid 1800’s. Afterward they started using more of what we think of as our standard energy materials such as coal and petroleum. The 20th century is when sources we now consider alternative started to appear such as hydraulic, nuclear, solar and natural gas.

The petroleum industry consists of two separate operations: Upstream and Downstream Operations. Upstream operations involve exploration of new oil reserves, development of oil fields, constructing the well-head and crude oil production facilities. Downstream operations cover processing of crude oil in petroleum refineries to produce liquid and gaseous fuels and materials for the market. This course addresses petroleum refining to review how a variety of physical processes and chemical reactions in separate refinery units are integrated to process compliant fuels and materials.

Learning Outcomes

By the end of this lesson, you will be able to:

- recognize the significance of petroleum fuels in the U.S. energy supply;

- express the overall objectives of petroleum refining;

- identify the economic and environmental drivers of petroleum refining;

- describe the overall approach to petroleum refining and categorize refinery processes and products;

- portray chemical constitution of petroleum.

What is due for Lesson 1?

This lesson will take us one week to complete. Please refer to the Course Syllabus for specific time frames and due dates. Specific directions for the assignments below can be found on the Assignment page within this lesson.

| Readings | J. H. Gary, G. E. Handwerk, Mark J. Kaiser, Chapter 1, pp. 1-12; Chapter 3, pp. 62-65 |

|---|---|

| Assignments | For your information, review the most recent supply of petroleum fuels from the data given at U.S. Energy Information Administration [3] (eia.gov) and research how petroleum refining addresses the environmental concerns from the combustion of petroleum fuels in internal combustion engines. |

Questions?

If you have any questions, please post them to our Help Discussion (not email), located in Canvas. I will check that discussion forum daily to respond. While you are there, feel free to post your own responses if you, too, are able to help out a classmate.

Market Drivers for the Refining Industry

Market Drivers for the Refining Industry

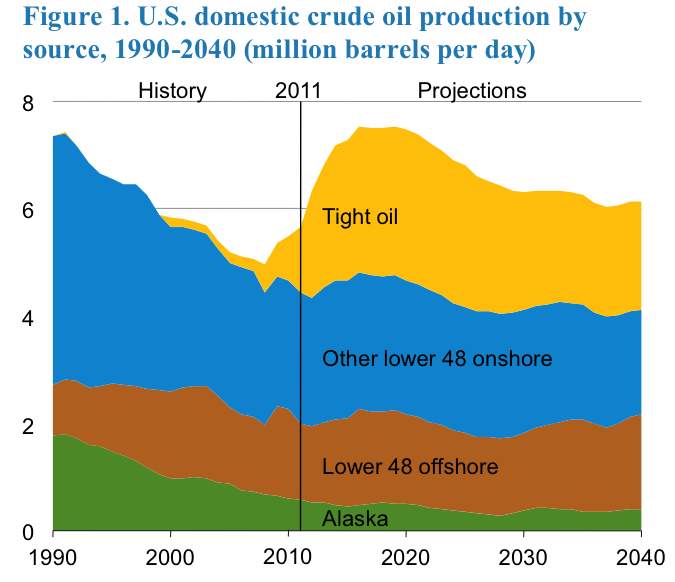

Markets and demand for refinery products depend on the dynamics of a global economy. It is generally agreed that oil and gas will continue to be the primary energy resource in the U.S. and world economies for decades to come. Because of the projected increase in the production of oil in tight formations, the United States is expected to become an exporter of petroleum products and crude oil after decades of being an importer (Figure 1.2, EIA Annual 2013, eia.gov). Petroleum fuels will continue to dominate the transportation sector, but the following trends should be noted:

- increasing fuel economy of vehicles (offset by increasing number of vehicles and miles driven);

- more strict environmental regulations with demand for cleaner fuels;

- biofuels as additives (e.g., ethanol, biodiesel) or alternative fuels in niche markets (jet fuel from algae);

- demand for high-quality, high-performance fuels

Figure 1.2 is showing both the history of U.S. crude oil production since 1990 as well as the prediction of U.S. crude oil production until the year 2040. Since 1990, we have been seeing a decline in oil production from Alaska, offshore drilling, and lower 48 offshore production until 2010 and then those sources are predicted to level off. After 2010 it is predicted that oil production from tight oil will continue to increase.

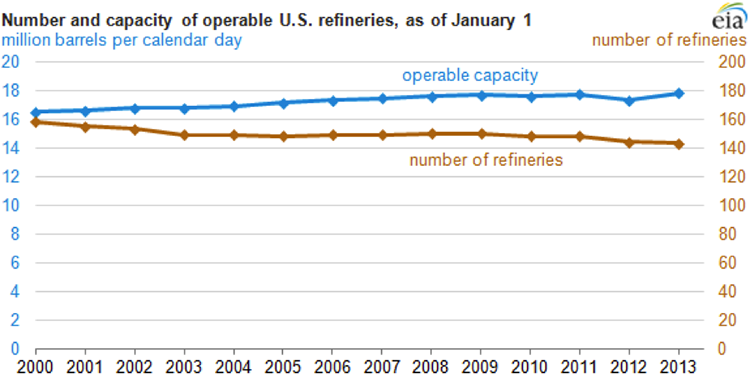

Competitive forces in the global economy lead to joint ventures and mergers and shutting down of inefficient refineries, or shutting down of processing units with low efficiency within refineries. Figure 1.3 shows the changes in the refinery capacity and number of refineries in the U.S. since 2000. The increasing refining capacity, with the decreasing number of refineries, results in the closing down of small inefficient refineries while expanding the large refineries.

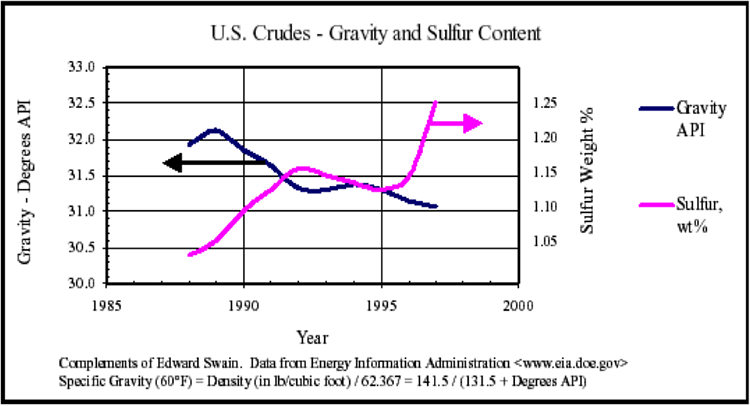

Regarding the global competition, the technological advancement addresses the degrading quality of crude oils to produce cleaner and higher quality petroleum fuels. On the supply side, there is the increasing abundance of natural gas liquids (ethane, propane, n-butane, and isobutane) due to increased shale gas production in the U.S. and elsewhere. These liquids enter refineries as new feedstock in addition to crude oil supply.

Refineries need process improvements to advance their capabilities to deal with the changing crude oil base and changing environmental regulations. These improvements in refinery processes would need to create and use, for example:

- new catalysts and new chemistry;

- more sophisticated process modeling and computational methods;

- more effective use of computers in refinery management;

- online monitoring and property measurements;

- new materials to reduce maintenance and extend the useful life of the equipment.

Concerns for efficiency include running a refinery efficiently and producing fuels that will burn efficiently in the combustion engines, as follows:

- Efficiency of refinery processes

- Minimize waste and optimize the yield and properties of the refinery products to obtain maximum value from the crude oil.

- Increase the energy efficiency of each unit in the refinery.

- Fuel economy in internal combustion engines

- Produce high-performance fuels for efficient operation of combustion engines.

An Overview of Refinery Products and Processes

An Overview of Refinery Products and Processes

Considering the market drivers just reviewed along the small profit margins that are often usually associated with petroleum refinery products, refineries should carefully select the crude oil feedstock and configure the refinery processes such that they produce the desirable petroleum products at the lowest cost.

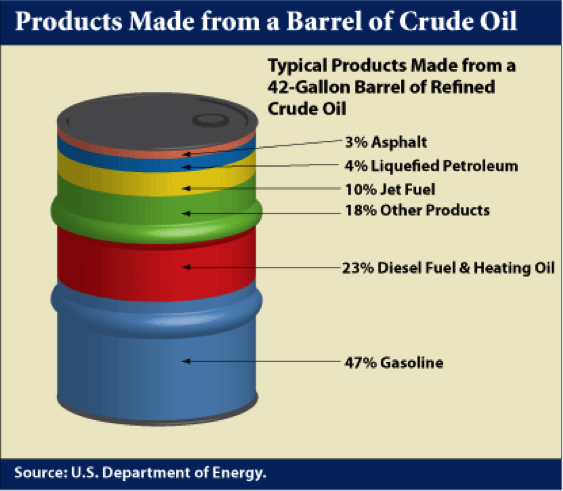

In the U.S. refineries, a principal focus is on the production of gasoline because of high demand. Diesel fuel is the principal refinery product in most other parts of the world. Figure 1.4 shows a typical distribution of products from a barrel of crude oil in a U.S. refinery. Distillation process separates the crude oil into boiling point fractions. The liquefied petroleum gas (LPG) constitutes the lowest boiling point (most volatile) product from a refinery and higher boiling fractions lead to most desirable distillate liquids, such as gasoline, jet fuel, diesel fuel, and fuel oil in the increasing order of boiling points, while asphalt is made from the residual fraction remaining after distillation.

Products Made from a Barrel of Crude Oil

-

47% Gasoline

-

23% Diesel Fuel & Heating Oil

-

18% Other Products

-

10% Jet Fuel

-

4% Liquefied Petroleum

-

3% Asphalt

The following animation shows a refinery flow chart indicating some of the major refinery processes and refinery products. Note that the distillation process (Fractionation Tower) separates crude oil into a number of distillate fractions that are sent as feedstocks to different processes, some of which are interconnected. It is also important to recognize that petroleum refining not only produces transportation fuels and fuels for space heating or industrial furnaces, but also produces materials needed for the operation of the combustion engines and paving the roads for vehicles to travel on.

Video: FSC 432 Refinery Flow Chart (4:12)

Here, we will build a simple refinery flow chart. On the left, you see the crude oil feed to the refinery. On the right hand side, the major refinery products, going from the lightest to the heaviest. Starting with gasoline, jet fuel and kerosene, heating and diesel fuels, industrial fuel oil, waxes, lubricating oils, greases, asphalt, and petroleum coke would be the heaviest product, which will be a solid obtained from a refinery.

The crude oil is fed to the fractionating tower that we call the distillation calm. We separate the crude oil into various boiling fractions. And these fractions are fed to the processes, the downstream, which are vapor recovery unit, also forming alkylation, catalytic cracking, extraction, coking, dewaxing, grease manufacturing, treating and blending, among others and there's additional processing there as well. So, we essentially will connect to crude oil through these processes to the final product.

Now, please note that some of the refinery units are connected. If you look at vapor recovery unit connected to catalytic cracking, that is also connected to coking. And at the top is ultraforming. Now, these processes all produce gasoline and light to hydrocarbons, like LPG, from different bonding fractions of crude oil coming from the distillation columns. That's why they're linked on this diagram.

Let's follow what happens to different distillation fractions coming from the distillation column. First, the vapor product from the top is sent to the vapor recovery unit, and separates into a gasoline and LPG-- that's liquified petroleum gas. You can see the ultraforming we call now, the process of Catalytic Reforming is involved to make a high-octane gasoline.

You can see that additional processing is also needed to remove sulfur out from these products. LPG as well as gasoline. We should note that catalytic cracking can also produce jet fuel. As you can see the arrow from cat cracking touching the jet fuel point. And catalytic cracking also produces feed stocks for the alkylation unit to produce additional high octane gasoline.

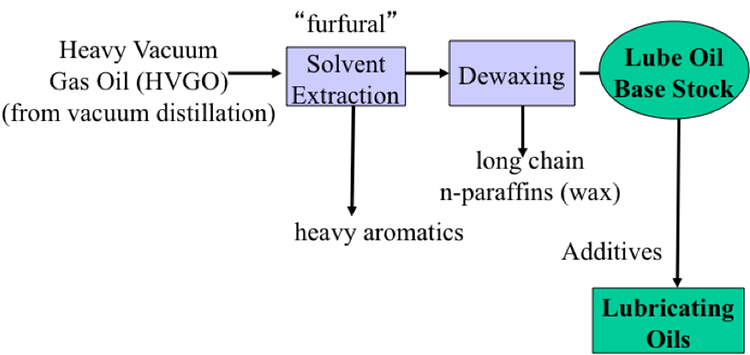

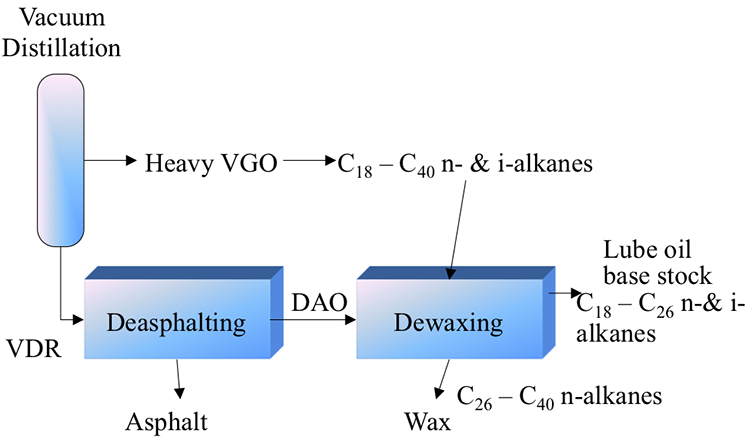

As we go down to the distillation column, we are now into the vacuum distillation territory, and the product from vacuum distillation would go through extraction, dewaxing, and various treating and blending to produce lubricating oils as well as waxes and greases.

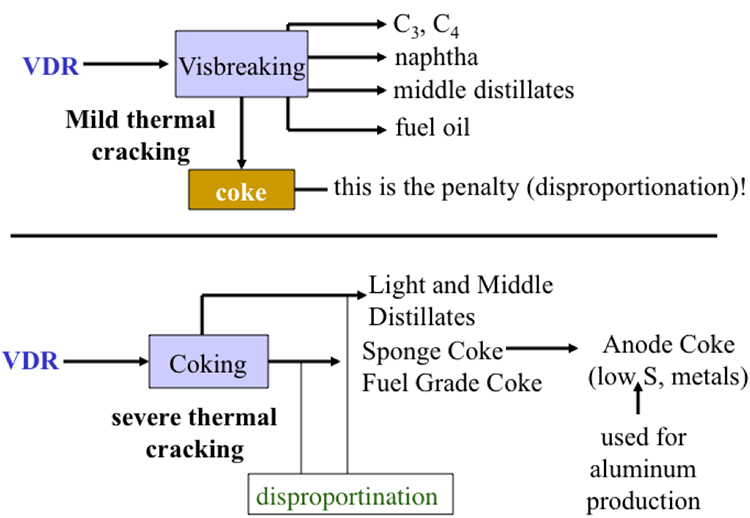

We are now at the bottom of the vacuum distillation column, the vacuum distillation residue can do various things with this fraction versus coking. It's a very severe thermal cracking process, which leads to petroleum coke as a byproduct. Refineries use coking to produce more jet fuel gasoline and then LPG. Petroleum coke is just a byproduct.

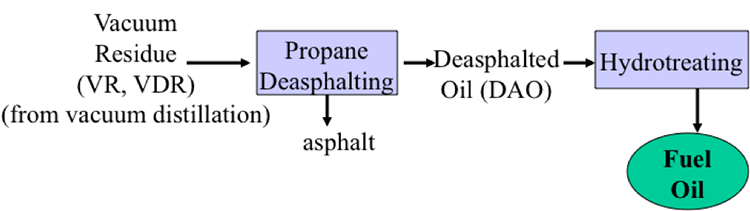

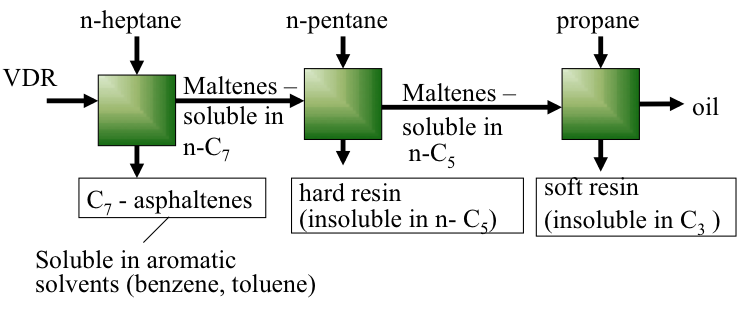

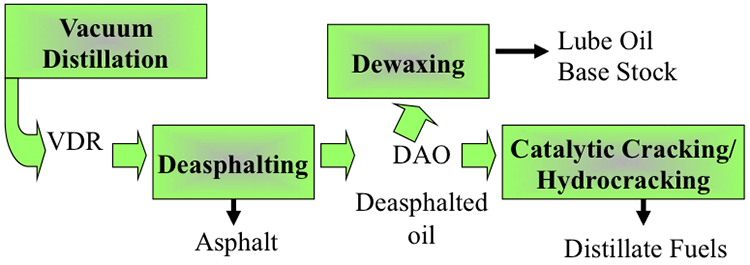

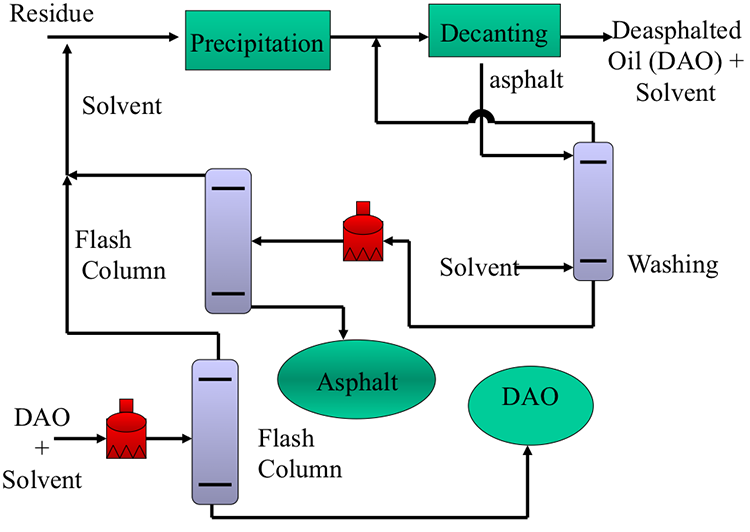

The vacuum distillation residue could be treated in a deasphalting process to produce asphalt. So, again, as a byproduct, the principal product from the deasphalting called the deasphalted oil could be used to making a lighter, hydrocarbons, fuels, and chemicals from this fraction.

And this pretty much completes building off a very simple refinery flow chart.

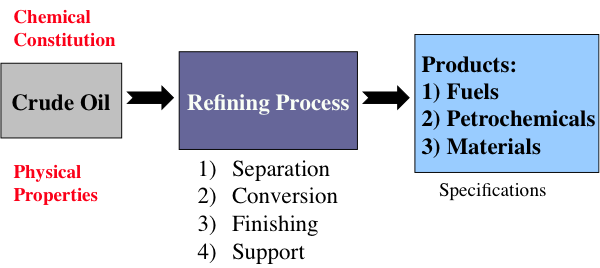

Figure 1.5 indicates that chemical constitution and physical properties of crude oils are important parameters that guide the refinery configurations. The refining processes can be divided into four groups, as indicated. While the separation processes involve just physical phenomena, the conversion, finishing, and support processes require chemical changes, i.e., breaking chemical bonds to modify the molecular structure of the feedstocks. These changes are necessary to produce the fuels and materials in accordance with industrial/commercial specifications.

This is a classification of refining processes and the types of refinery products, shown by a flow chart. The flow chart starts with crude oil. Above crude oil chemical constitution is written and below physical properties are written. Crude oil leads to the refining process including separation, conversion, finishing and support. From there it goes to products including fuels, petrochemicals and materials. Underneath this is written specifications.

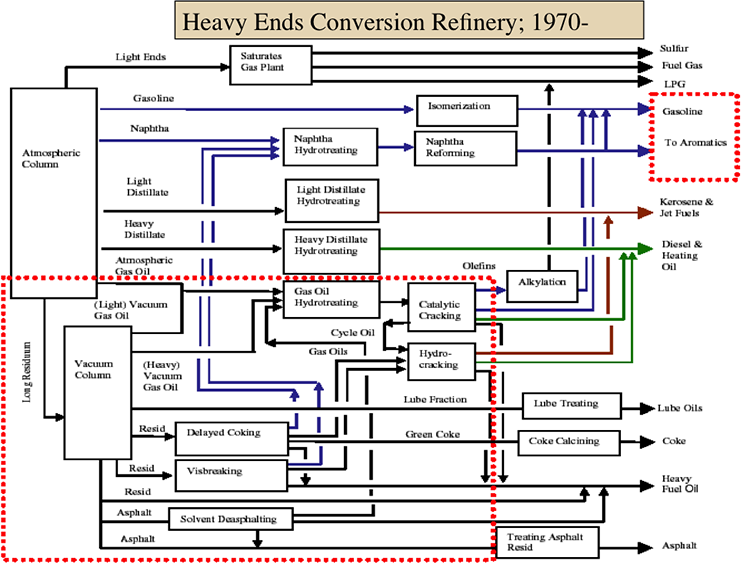

Figure 1.6 (progressive image, 25 seconds) shows a more detailed refinery block diagram to show how different processes are integrated for producing the desired fuels and materials.

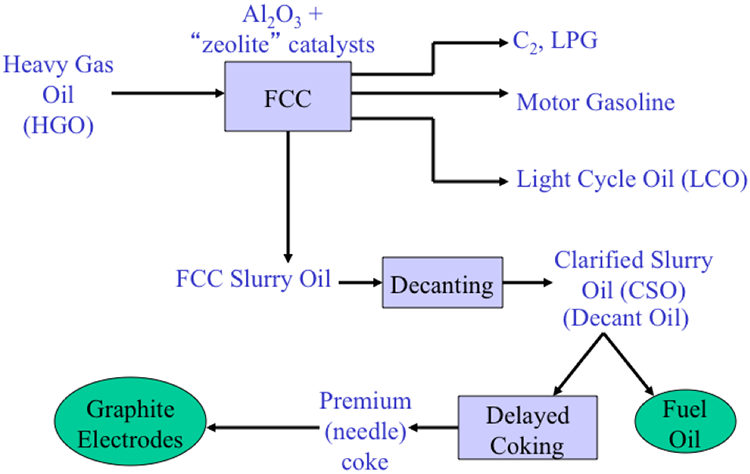

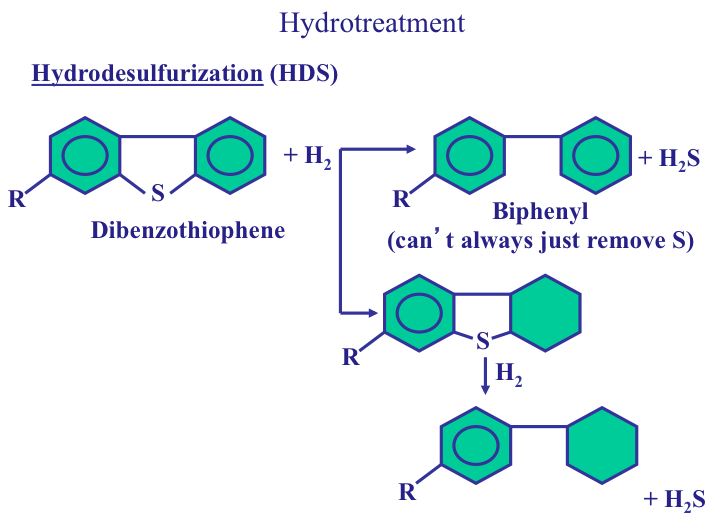

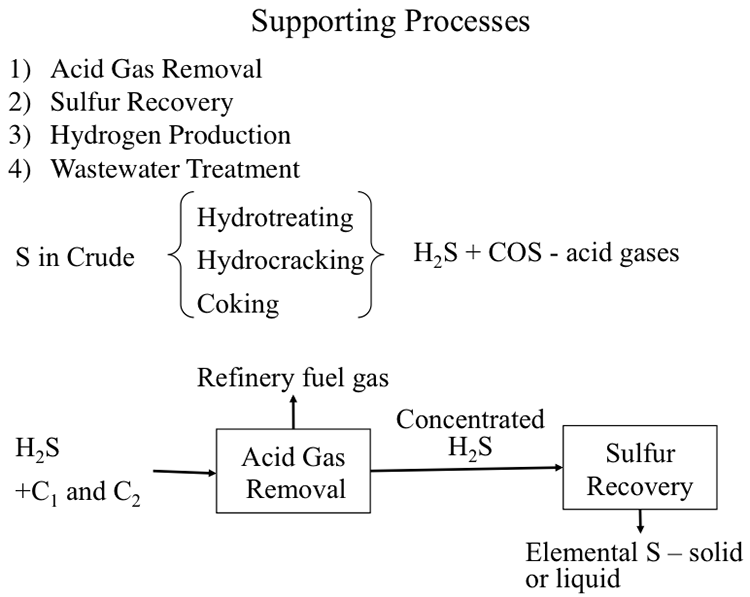

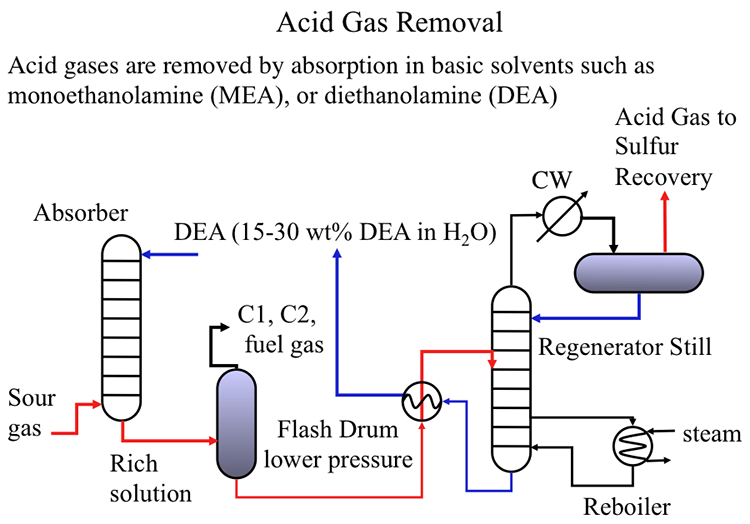

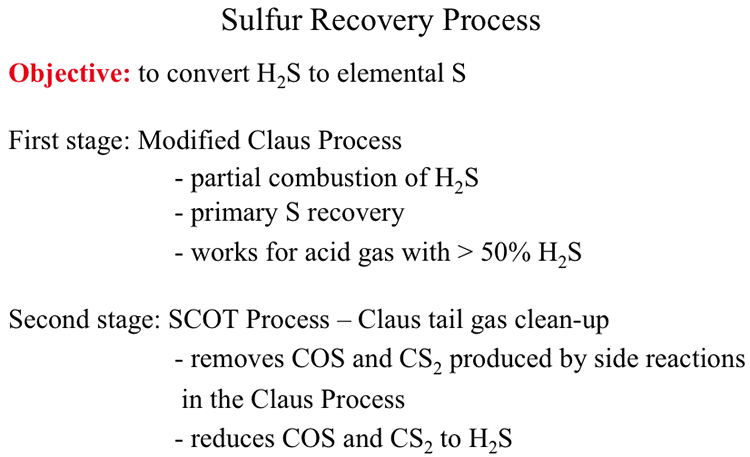

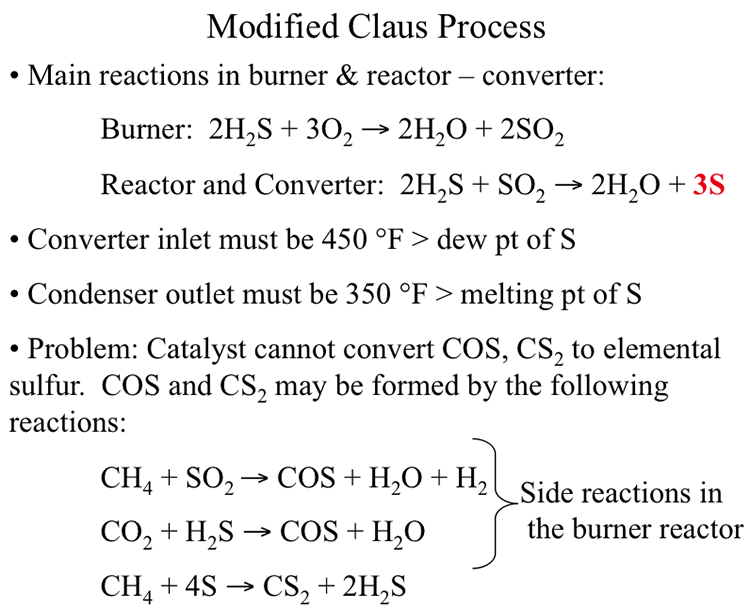

Separation processes, such as distillation, dewaxing, and deasphalting make use of the differences in the physical properties of crude oil components to separate groups of hydrocarbon compounds or inorganic impurities, whereas conversion processes cause chemical changes in the hydrocarbon composition of crude oils. For example, Fluid Catalytic Cracking process breaks chemical bonds in long-chain alkanes to produce shorter chain alkanes to produce gasoline from higher boiling gas oil fractions. Finishing processes involve hydrotreating to remove heteroatoms (S, N, and metals) and product blending to produce fuels and materials with desired specifications and in compliance with environmental and government regulations. Finally, supporting processes provide the recovery of the removed heteroatoms or heteroatom compounds, production of the hydrogen necessary for conversion and hydrotreating processes, and effluent water treatment systems.

Knowledge Check

Why is diesel fuel preferred over gasoline in many countries in the world?

ANSWER: Diesel fuel powers the engines in buses, locomotives, and ships used for public transport. Passenger vehicles fueled by gasoline are the most widely used means of transportation in the U.S.

Chemical Constitution of Crude Oil

Chemical Constitution of Crude Oil

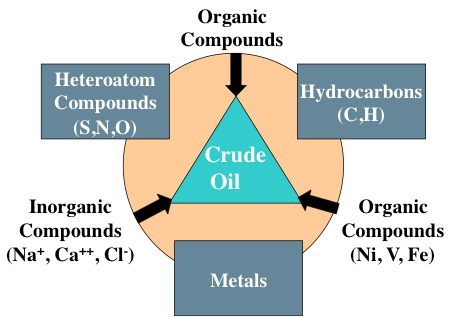

Crude oil contains organic compounds, heteroatom compounds (S,N,O), hydrocarbons (C, H), metals and organic (Ni, V, Fe) and inorganic (Na+, Ca++, Cl-) compounds as listed in Figure 1.7. Compounds that contain only elements of carbon and hydrogen are called hydrocarbons and constitute the largest group of organic compounds found in petroleum. There might be as many as several thousand different hydrocarbon compounds in crude oil. Hydrocarbon compounds have a general formula of CxHy, where x and y are integer numbers.

Triangle labeled Crude Oil. On each corner is:

Inorganic Compounds (Na+, Ca2+, Cl-)

Organic Compounds (Ni, V, Fe)

Organic Compounds

On each side they are labeled:

Between organic and inorganic compounds: Heteroatom compounds (S,N,O)

Between organic and Organic (Ni, V, Fe) compounds: Hydrocarbons (C,H)

Between Organic (Ni, V, Fe) and inorganic compounds: Metals

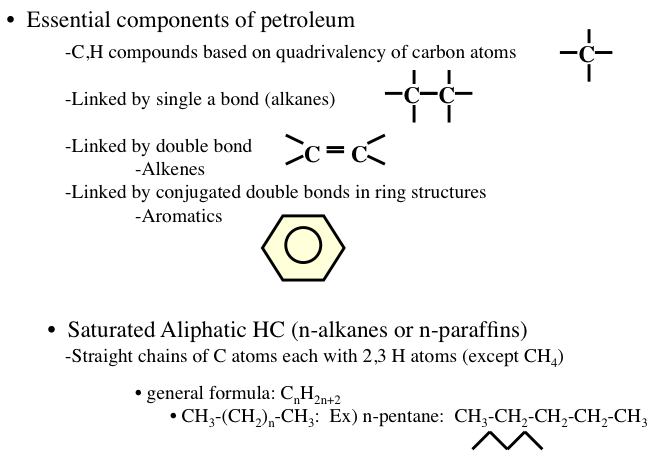

Hydrocarbons are generally divided into four groups: (1) paraffins, (2) olefins, (3) naphthenes, and (4) aromatics (Figure 1.8). Among these groups, paraffins, olefins, and naphthenes are sometimes called aliphatic compounds, as different from aromatic compounds. The lightest hydrocarbon found as a dissolved gas is methane (CH4), the main component of natural gas. Olefins are not usually found in crude oils, but produced in a number of refining processes.

Image reads:

Essential components of petroleum

-CH compounds based on quadrivalency of carbon atoms

-linked by a single bond (alkanes)

-liked by a double bond (alkenes)

-linked by conjugated double bonds in a ring structure (aromatics)

Saturated Aliphatic HC (n-alkanes or n-paraffins)

-straight chains of C atoms each with 2, 3 H atoms (except CH4)

-general formula: CnH2n+2

-CH3-(CH2)n-(CH3): Ex) n-pentane: CH3-CH2-CH2-CH2-CH3

Aromatic Hydrocarbons

Aromatic Hydrocarbons

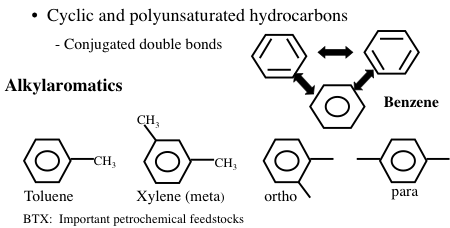

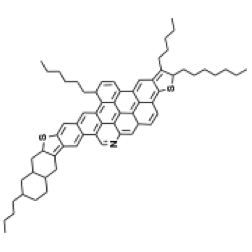

Aromatic hydrocarbons are an important series of hydrocarbons found in almost every petroleum mixture from any part of the world. Aromatics are cyclic but unsaturated hydrocarbons with alternating double bonds (Figure 1.12). The simplest aromatic hydrocarbon is benzene (C6H6). The name “aromatic” refers to the fact that such hydrocarbons are commonly fragrant compounds. Although benzene has three carbon-carbon double bonds, it has a unique arrangement of electrons with resonance structures of the double bonds (aromaticity) that allow benzene to be relatively stable. However, benzene is known to be a cancer-inducing compound. For this reason, the amount of benzene allowed in petroleum products such as gasoline or fuel oil is limited by government regulations in many countries. Under standard conditions, benzene, toluene, and xylene are in liquid form whereas higher aromatics such as naphthalene occur as solids in isolation, but dissolve to form a liquid solution with simple aromatics.

Image Shows Cyclic and polyunsaturated hydrocarbons with conjugated double bonds. Specifically:

Benzene: six carbon ring with no side chains

Alkylaromatics:

-Toluene: benzene with a methyl group on carbon 1

-Xylene (meta): benzene with a methyl group on carbons 1 & 3

-Ortho: benzene with a methyl group on carbon 1&2

-Para: benzene with a methyl group on carbon 1&4

Knowledge Check

What constitutes the white crystals of moth balls?

ANSWER: Napthalene! Naphthalene is an effective moth killer because it sublimes (forms a vapor from a solid without going through a liquid state) at room temperature.

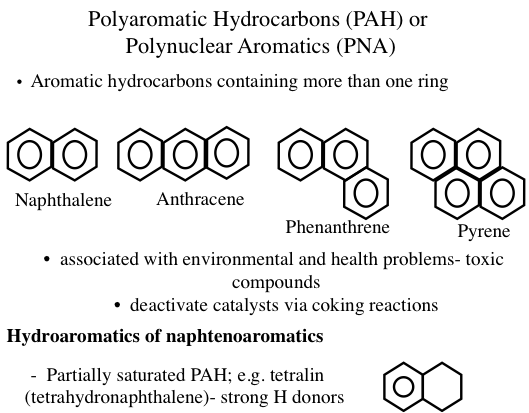

Polyaromatic and Hydroaromatic Compounds

Polyaromatic and Hydroaromatic Compounds

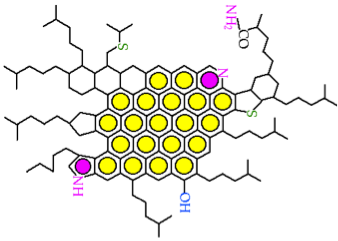

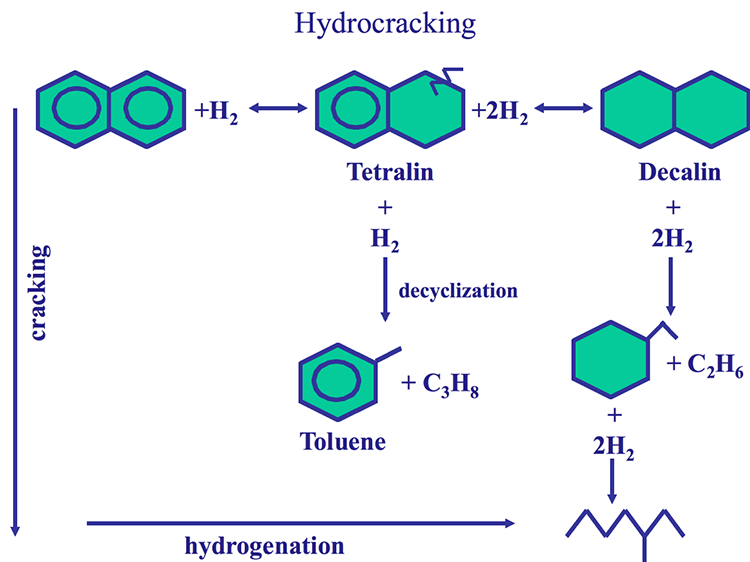

Some of the common aromatics found in crude oil and petroleum products are benzene derivatives with attached methyl, ethyl, propyl, or higher alkyl groups. This series of aromatics is called alkylbenzenes, and compounds in this homologous group of hydrocarbons have the general formula of CnH2n-6 (where n ≥ 6). Generally, an aromatic series with only one benzene ring is also called mono- aromatics or mononuclear aromatics. However, heavy petroleum fractions and residues contain unsaturated multirings with many benzene and naphthene rings attached to each other. Such aromatics that exist as solids in isolation are also called polyaromatic hydrocarbons (PAHs) or polynuclear aromatics (PNAs) (Figure 1.13). Heavy crude oils usually contain more aromatics than light crudes. It is common to have compounds with naphthenic and aromatic rings side by side (hydroaromatics, or naphthenoaromatics, Figure 1.13) especially in heavy fractions.

Figure 1.13 shows examples of PAHs, such as anthracene, phenathrene, and pyrene. The configuration of rings in PAHs strongly influences the physical and chemical properties of these compounds. For example, three-ring aromatics anthracene and phenanthrene have significantly different properties. In petroleum, PAHs exist mostly as alkyl substituted ring systems such that the substitutent alkyl groups (e.g., methyl, ethyl) replace (substitute for) the hydrogen atoms on the rings.

Image Reads:

Polyaromatic Hydrocarbons (PAH) or Polynuclear Aromatics (PNA)

Aromatic hydrocarbons containing more than one ring:

-Ex) Naphthalene, Anthracene, Phenanthrene, Pyrene

-Associated with environmental and health problems – toxic compounds

-deactivate catalysts via coking reactions

Hydroaromatics of naphtenoaromatics

-partially saturated PAH; e.g. tetralin (tetrahydronapthalene) – strong H donors

Normally, high-molecular-weight polyaromatics contain several heteroatoms such as sulfur, nitrogen, or oxygen, but these compounds are still called aromatic compounds because their electronic configurations maintain the aromatic character.

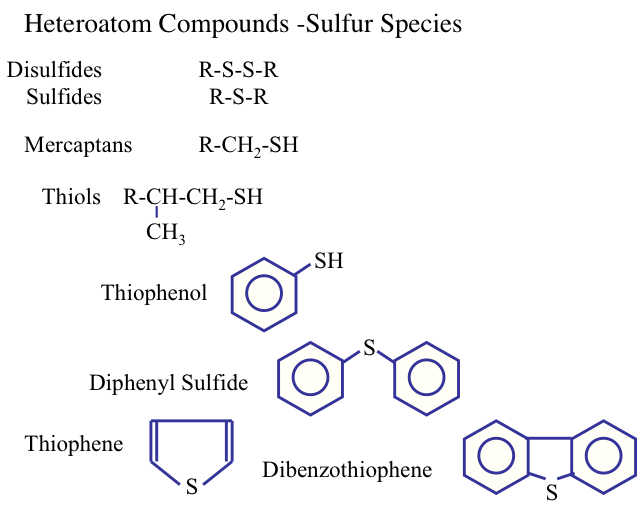

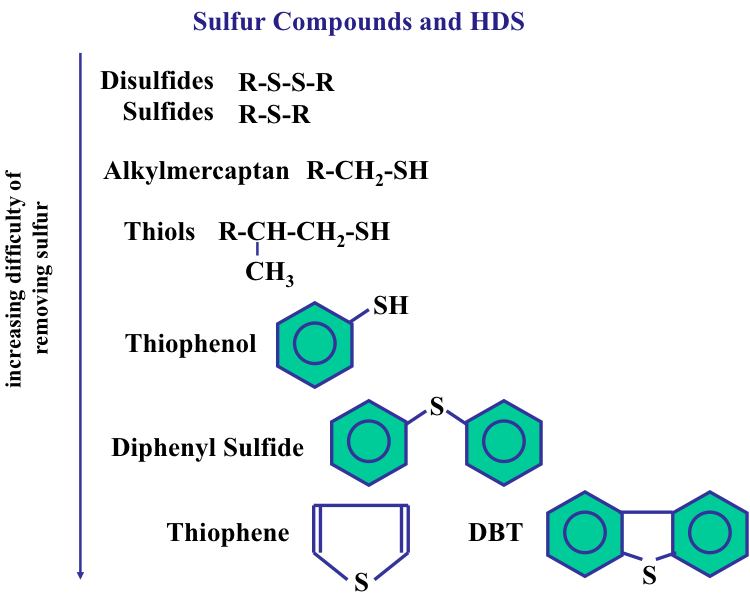

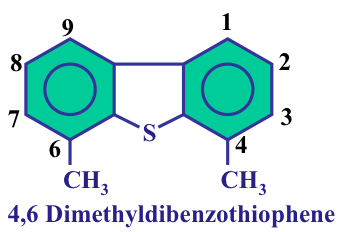

Sulfur is the most important heteroatom found in crude oil and refinery products petroleum, and it can be found in cyclic (e.g., thiophenes) and noncyclic compounds such as mercaptans (R-S-H) and sulfides (R-S- R′), where R and R′ are alkyl groups. Sulfur in natural gas is usually found in the form of hydrogen sulfide (H2S). Figure 1.14 shows the types of sulfur compounds in crude oils. The amount of sulfur in a crude oil may vary from 0.05 to 6 % by weight. The presence of sulfur in finished petroleum products is not desirable. For example, the presence of sulfur in gasoline can promote corrosion of engine parts and produce sulfur oxides upon combustion, contributing to air pollution.

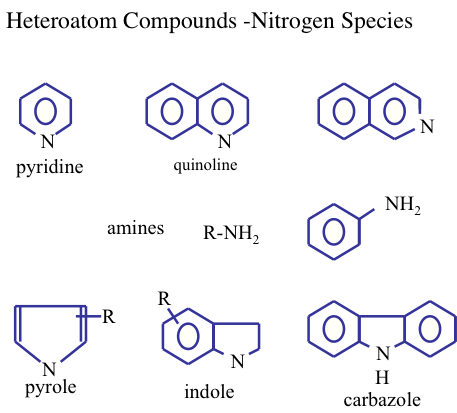

Normally, the concentration of the other heteroatom compounds (nitrogen, oxygen, and metals) in crude oils is usually lower than that of the sulfur compounds. Figure 1.15 shows the nitrogen compounds that may be found in crude oils.

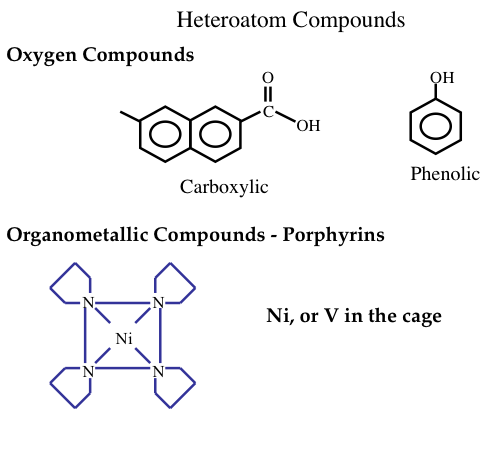

Generally, in heavier crude oils the proportions of carbon, sulfur, nitrogen, and oxygen compounds are higher at the expense of hydrogen content. Heavier crude oils also contain organometallic compounds of common nickel and vanadium (Figure 1.16). These compounds are highly corrosive and toxic and should be removed in the refinery. Nickel, vanadium, and copper can also severely affect the activities of catalysts and result in lower quality products. Organometallic compounds tend to concentrate in heavy, or residual fractions of crude oils.

Knowledge Check

What is the principal type of air pollution caused by the emission of sulfur oxides into the atmosphere?

ANSWER: Acid rain, caused by the formation of sulfuric acid through reactions of the sulfur oxides in the atmosphere.

Paraffins

Paraffins

Paraffins are also called alkanes and have the general formula of CnH2n+2, where n is the number of carbon atoms in a given molecule. Paraffins are divided into two groups of normal and isoparaffins. Normal paraffins or normal alkanes are simply written as n-paraffins or n-alkanes, and they are open, straight-chain saturated hydrocarbons. The second group of paraffins is called isoparaffins, which are branched-type hydrocarbons, and they begin with isobutane (also called methylpropane), which has the same closed formula as n-butane (C4H10). Compounds of different structures with the same closed formula are called isomers (Figure 1.9). For example, the open formula for n-butane, n-C4, can be shown as CH3-CH2-CH2-CH3, based on the quadrivalency of the carbon atom, and for simplicity, only the carbon-carbon bonds are drawn and most C-H bonds are omitted, as shown in Figure 1.7 and 1.8 on the previous page. Paraffins are the largest series of hydrocarbons found in petroleum and beginning with the simplest compound, methane.

Under standard conditions of temperature and pressure (STP), the first four members of the alkane series (methane, ethane, propane, and butane) are in gaseous form, and compounds starting from C5H12 (pentane) to n-heptadecane (C17H36) are liquids (constituting large fractions of hydrocarbons found in liquid fuels (e.g., gasoline, jet fuel, and diesel fuel), whereas n-octadecane (C18H38) or heavier compounds exist in isolation as wax-like solids at STP. These heavier paraffins are soluble in lighter paraffins or other hydrocarbons and can be found in diesel fuel and fuel oils. Paraffins from C1 to C40 usually appear in crude oil (heavier alkanes in liquid solution, not as solid particles) and represent up to 20% of crude by volume.

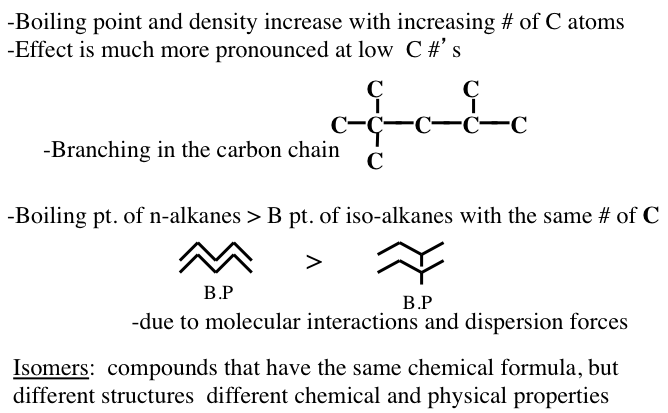

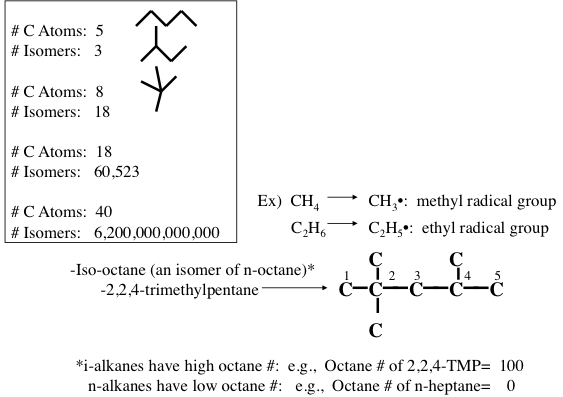

Figure 1.10 shows the statistically possible number of isomers of paraffins that increase exponentially with carbon number, starting with just one isomer for butane, reaching approximately 60,000 for C18 paraffins. Note that the branching in hydrocarbons causes significant changes in physical properties (e.g., boiling point and density, Figure 1.11) and chemical behavior (e.g., octane number, Figure 1.10) of paraffins with the same carbon number. Note in Figure 1.10 that the removal of an H atom from alkanes generates free radicals (reactive species containing unpaired electrons) that are called alkyl species (e.g., methyl formed from methane and ethyl formed from ethane by removing a hydrogen atom) also a radical with an unpaired electron. Also note the nomenclature using alkyl groups to specifically name isoalkanes (e.g., 2,2,4-trimethylpentane to designate a specific iso-octane).

Image Reads:

Boiling point and density increase with increasing # of carbon atoms

Effect is much more pronounced at low carbon #’s

Boiling point of n-alkanes is greater than the boiling point of iso-alkanes with the same # of carbons

-Due to molecular interactions and dispersion forces

Isomers: compounds that have the same chemical formula but different structures and different chemical and physical properties

Image Reads

| # of Carbons | # of Isomers |

|---|---|

| 5 | 3 |

| 8 | 18 |

| 18 | 60,523 |

| 40 | 6.2x1012 |

Iso-octane (an isomer of n-octane): 2,2,4-trimethylpentane

-i-alkanes have high octane #’s: e.g. Octane # of 2,2,4-TMP = 100

-n alkanes have low octane #’s: e.g. Octane # of n-heptane = 0

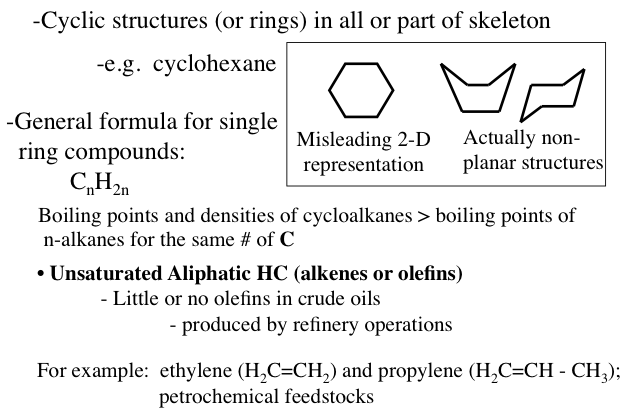

Naphthenes or cycloalkanes are rings or cyclic saturated hydrocarbons with a general formula of CnH2n5H10), cyclohexane (C6H12), and their derivatives such as n-alkylcyclopentanes are normally found in crude oils.

Image Reads:

Cyclic structures (or rings) in all or part of the skeleton.

-e.g cyclohexane

The general formula for single ring compounds: CnH2n

-Boiling points and densities of cycloalkanes are greater than the boiling points on n-alkanes with the same # of carbons

-For example: ethylene (H2C=CH2) and propylene (H2C=CH-CH3); petrochemical feedstocks

Unsaturated Aliphatic HC (alkenes or olefins)

-little or no olefins in crude oils (produced by refinery operations)

A hexagon is a misleading 2-D representation of cyclohexane the actual structure looks more like a boat or a chair

Assignments

Assignment Reminder

Each week, you will be required to do assignments. The assignment for this week is:

For your information (no submission), review the most recent supply of petroleum fuels from the data given at U.S. Energy Information Administration [4] and research how petroleum refining addresses the environmental concerns from the combustion of petroleum fuels in internal combustion engines.

Self-Check Questions

Self-Check Questions

Take a few minutes to answer the five questions below. Use the arrow to go to the next question. When you are ready, click Check to see the solution.

Summary and Final Tasks

Summary

Petroleum, the most important crude oil, consists of a mixture of hydrocarbon compounds including paraffinic, naphthenic, and aromatic hydrocarbons with small amounts of impurities including sulfur, nitrogen, oxygen, and metals. The first process in petroleum refining operations is the separation of crude oil into its major constituents, using distillation to separate the crude oil constituents into common boiling-point fractions. Other separation processes include deasphalting to remove the heaviest fraction of crude oil, asphalt, and dewaxing to remove long-chain n-paraffins called wax.

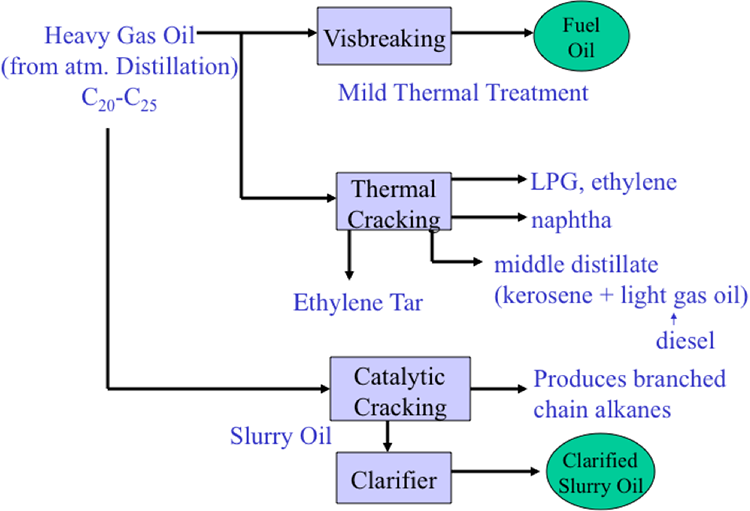

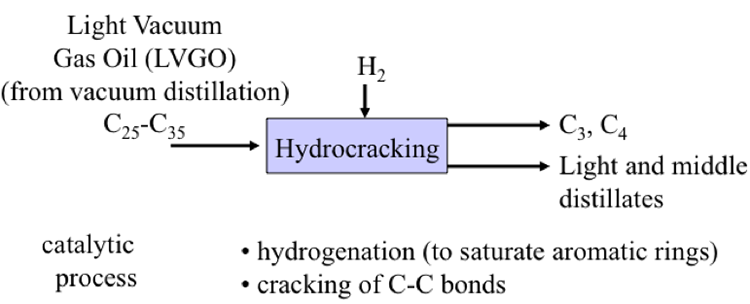

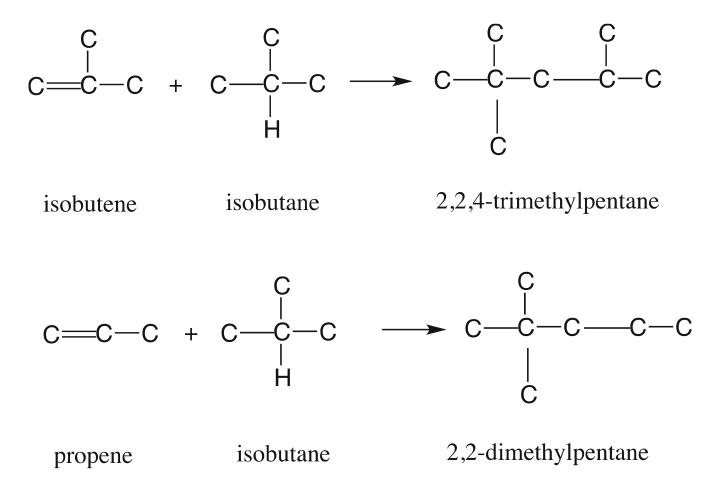

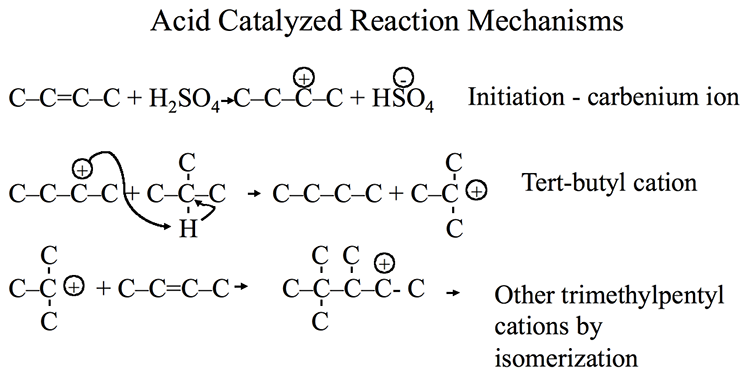

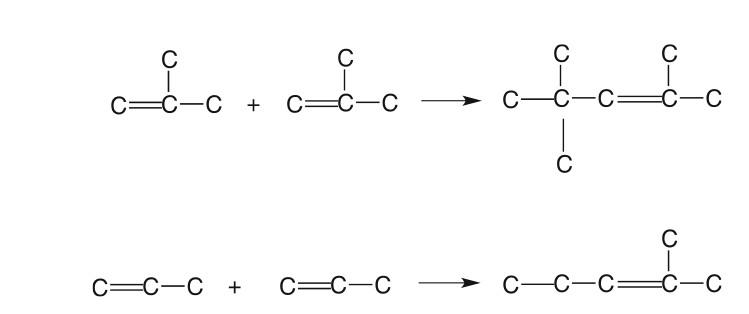

To meet the demands for high-octane gasoline, jet fuel, and diesel fuel, heavier components of crude oils are converted to gasolines and other distillate fuels. Among the conversion processes are cracking, coking, and visbreaking that are used to break large petroleum molecules into smaller ones. Polymerization and alkylation processes are used to combine molecules smaller than those in gasoline into larger ones to make more gasoline in the refinery. Isomerization and reforming processes are applied to rearrange and reform the structure of hydrocarbons to produce higher-value gasoline components of a similar molecular size.

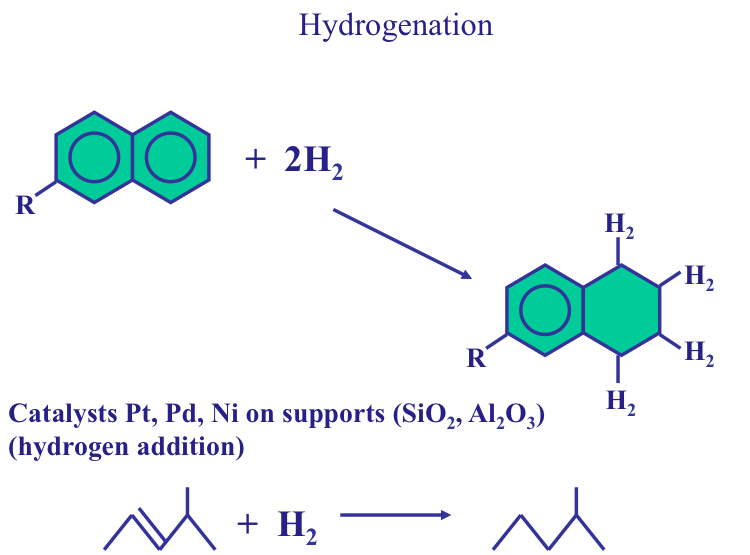

Finishing processes in a refinery processes stabilize and upgrade petroleum products by hydrogenation and remove undesirable elements, such as sulfur and nitrogen, by hydrotreating processes. Blending of many product streams, to come up with commercial refinery products with the required specifications, also belong to the category of finishing processes.

Lesson Objectives

You should now be able to:

- recognize the significance of petroleum fuels in the U.S. energy supply;

- express the overall objectives of petroleum refining;

- identify the economic and environmental drivers of petroleum refining;

- describe the overall approach to petroleum refining and categorize refinery processes and products;

- portray chemical constitution of petroleum.

Reminder - Complete all of the Lesson 1 tasks!

You have reached the end of Lesson 1! Double-check the to-do list below to make sure you have completed all of the activities listed there before you begin Lesson 2. Please refer to the Course Syllabus for specific time frames and due dates. Specific directions for the assignment below can be found within this lesson.

| Readings | J. H. Gary, G. E. Handwerk, Mark J. Kaiser, Chapter 1, pp. 1-12; Chapter 3, pp. 62-65 |

|---|---|

| Assignments | For your information, review the most recent supply of petroleum fuels from the data given at The U.S. Energy Information Administration website [3] (eia.gov) and research how petroleum refining addresses the environmental concerns from combustion of petroleum fuels in internal combustion engines. |

Questions?

If you have any questions, please post them to our Help Discussion (not email), located in Canvas. I will check that discussion forum daily to respond. While you are there, feel free to post your own responses if you, too, are able to help out a classmate.

Lesson 2: Properties and Classification of Crude Oil

Lesson 2 Overview

Lesson 2 Overview

Video: FSC 432 Lesson 2 (2:27)

In lesson two, we will talk about the properties and classifications of crude oil. Because of the extreme complexity of crude oil, it is impossible to get the molecular analysis, or the molecular composition. Because of this reason, people, even in the very early days of refinery, they developed some techniques to use easily measurable physical properties, such as density or viscosity, to make inferences about the molecular composition of crude oils.

This information is very important for refiners to adjust operating conditions in many units that are all integrated in the whole refinery. So to get these properties is really critical. And that can be easily measured in the laboratory.

What is important and fascinating to see that some classification parameters or characterization factors use these easily measurable properties to make inferences on the chemical constitution, chemical composition, of the oil. From physical properties to chemical composition.

You know that crude oil contains, essentially, hydrocarbons that are paraffinic or naphthenic and aromatic. So, using these characterization factors could classify the crude oils into these three subcategories. But beyond that, if you do have information on the hydrocarbon composition, you could use a more sophisticated classification system to divide crude oils into six classes.

Again, these are very important in terms of informing the refiners what to expect from this crude oil, how they can adjust the operating parameters so that they can produce the products that they would like and the properties of these products, the quality of the products-- to make these adjustments, to reach these refinery goals and objectives, in general. So see you in class after this.

Overview

Physical properties and composition of crude oil provide critical information for the optimum operation of a petroleum refinery. This information does not only help predict the physical behavior of crude oil in refinery units, but also gives insight into its chemical composition. Therefore, the physical properties can be related to chemical properties of crude oil and its fractions and the characteristics of the resulting refinery products. The most important properties of crude include density, viscosity, boiling point distribution, pour point, and the concentration of various contaminants.

Learning Outcomes

By the end of this lesson, you should be able to:

- define the significant properties of crude oil, including density, viscosity, average boiling point, sulfur, and salt content;

- understand the significance of crude oil properties in terms of refinery objectives, and describe crude oil assay;

- define and interpret the classification factors (Watson, UOP, VGC, and BMCI) as they relate to the hydrocarbon composition of crude oils;

- calculate average boiling points for crude oils using different averaging techniques and differentiate Watson and UOP characterization factors;

- analyze the elemental composition of crude oils and outline ternary classification of crude oils with respect to hydrocarbon composition, i.e., aromatics, paraffins, and naphthenes;

- assess the use of ternary classification of crude oils to estimate the refinery product yields.

What is due for Lesson 2?

This lesson will take us one week to complete. Please refer to the Course Syllabus for specific time frames and due dates. Specific directions for the assignments below can be found on the Assignments page within the Lesson.

| Readings | J. H. Gary, G. E. Handwerk, Mark J. Kaiser, Chapter 3, pp. 57-61, 65-70 and the course material from this site |

|---|---|

| Assignments | Exercise 1 - Submit to the Exercise 1 Assignment in the Lesson 2 Module.

|

Questions?

If you have any questions, please post them to our Help Discussion (not email), located in Canvas. I will check that discussion forum daily to respond. While you are there, feel free to post your own responses if you, too, are able to help out a classmate.

API Gravity

API Gravity

Density is defined as mass per unit volume of a fluid. The density of crude oil and liquid hydrocarbons is usually reported in terms of specific gravity (SG) or relative density, defined as the density of the liquid material at 60°F (15.6°C) divided by the density of liquid water at 60°F. At a reference temperature of 15.6°C, the density of liquid water is 0.999 g/cm3 (999 kg/m3), which is equivalent to 8.337 lb/gal (U.S.). Therefore, for a hydrocarbon or a petroleum fraction, the SG is defined as:

In the early years of the petroleum industry, the American Petroleum Institute (API) adopted the API gravity (°API) as a measure of the crude oil density. The API gravity is calculated from the following equation:

The API scale for gravity was adapted from the Baumé scale, developed in the late 18th century to be used in hydrometers for measuring even small differences in the specific gravity of liquids, using water as a reference material in these devices. A liquid with SG of 1 (i.e., water) has an API gravity of 10. One can note from Eq. 1 that liquid hydrocarbons with lower SGs have higher API gravities. The API of crude oils varies typically between 10 and 50, with most crude oils falling in the range of 20-45. Using API gravity, the conventional crude oils can be generally considered as light (°API>30), medium (30>°API>22), and heavy (°API<22).

Note that the relationship between °API and specific gravity is not linear. Therefore, the °API gravity of crude blends cannot be calculated by linear averaging of the component °APIs. Specific gravities of the components can be averaged, though, to determine the specific gravity of the resulting blend. In practice, averaging °APIs is usually accepted because the error involved in averaging is small.

Among the hydrocarbons, aromatic hydrocarbons have higher SG (lower °API) than paraffinic hydrocarbons with the same number of carbon atoms. For example, benzene has an SG of 0.883 (°API of 28.7), whereas n-hexane has an SG of 0.665 (°API of 81.3). Therefore, the heavy (high-density) crude oils tend to have high concentrations of aromatic hydrocarbons, whereas the light (low-density) crude oils have high concentrations of paraffinic hydrocarbons.

Viscosity

Viscosity

Viscosity, commonly depicted by the symbol μ, is a physical property of a fluid that describes its tendency/resistance to flow. A high-viscosity fluid has a low tendency to flow, whereas low-viscosity fluids flow easily. Newton’s Law of Viscosity provides a physical definition of viscosity. Power requirement to transport (e.g., to pump) a fluid depends strongly on the fluid’s viscosity. Interestingly, the viscosity of liquid decreases with increasing temperature, while viscosity of gases increases with increasing temperature. Among petroleum products, viscosity constitutes a critically important characteristic of lubricating engine oils. Viscosity of liquids is usually measured in terms of kinematic viscosity, which is defined as the ratio of absolute (dynamic) viscosity to absolute density (ν = μ/ρ). Kinematic viscosity is expressed in units of centistokes (cSt), Saybolt Universal seconds (SUS), and Saybolt Furol seconds (SFS). Values of kinematic viscosity for pure liquid hydrocarbons are usually measured and reported at two reference temperatures, 38°C (100°F) and 99°C (210°F) in cSt. However, different reference temperatures, such as 40°C (104 °F), 50 °C (122 °F), and 60 °C(140 °F), are also used to report kinematic viscosities of petroleum fractions. The viscosity of crude oils can be measured using a standard method (ASTM D2983).

Knowledge Check

What are ASTM, ISO, IP?

ANSWER:

There are several international organizations that are known as standard organizations, and they recommend standard measuring techniques for petroleum products. These organizations include [2 in mnl]

-ASTM - American Society for Testing and Materials (http://www.astm.org(link is external) [6] ASTM includes several committees depending on the materials; D committee is responsible for petroleum products and for this reason its test methods for petroleum materials are designated by the prefix D.

- ISO - International Organization for Standardization (http://www.iso.org [7])

- Energy Institute (formerly IP) (http://uk.ihs.com/collections/ [8])

- API - American Petroleum Institute) (http://www.api.org [9])

- AFNOR - Association Francaise de Normalisation (http://www.afnor.org [10])

Pour Point

Pour Point

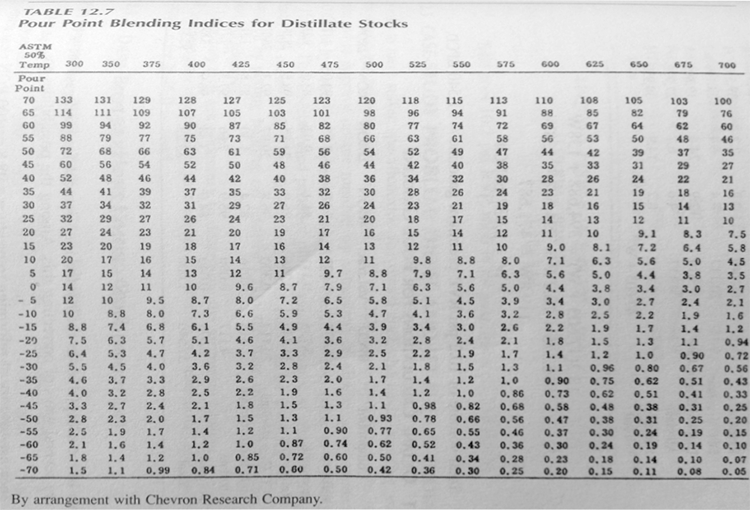

The pour point of a crude oil, or a petroleum fraction, is the lowest temperature at which the oil will pour or flow when it is cooled, without stirring, under standard cooling conditions. Pour point represents the lowest temperature at which oil is capable of flowing under gravity. It is one of the important low-temperature characteristics of high-boiling fractions. When the temperature is less than the pour point of a petroleum product, it cannot be stored or transferred through a pipeline. Standard test procedures for measuring pour points of crude oil or petroleum fractions are described in the ASTM D97 (ISO 3016 or IP 15) and ASTM D5985 methods. The pour point of crude oils relates to their paraffin content: the higher the paraffin content, the higher the pour point.

Knowledge Check

What are Waxes?

ANSWER: Waxes are microcrystalline solids at ambient temperatures that consist, typically, of normal alkanes with carbon number between 20 and 40. Therefore, knowledge of the pour point and freezing point of crude oils is also important.

Concentration of Various Contaminants

Concentration of Various Contaminants

In addition to hydrocarbons, crude oil contains hetroatom (S, N, metals) species that need to be removed if their concentrations are higher than the specified thresholds. Other impurities in crude oil include salt and sediment and water. The acidity of crude oil is also important, particularly for concerns of corrosion in pipes or other process units. Carbon residue of a crude oil indicates the tendency to generate coke on heter tubes or rector surfaces. All of these contaminants and properties of crude oils are measured using standard methods, as described in this section.

Sulfur and Nitrogen Content

Sulfur and Nitrogen Content

Sulfur Content

Sulfur content of crude oils is the second most important property of crude oils, next to API gravity. Sulfur content is expressed as weight percent of sulfur in oil and typically varies in the range from 0.1 to 5.0%wt. The standard methods that are used to measure the sulfur content are ASTM D129, D1552, and D2622, depending on the sulfur level. Crude oils with more than 0.5%wt sulfur need to be treated extensively during petroleum refining. Using the sulfur content, crude oils can be classified as sweet (<0.5%wt S) and sour (>0.5% %wt S). The distillation process segregates sulfur species in higher concentrations into the higher-boiling fractions and distillation residua. Removing sulfur from petroleum products is one of the most important processes in a refinery to produce fuels compliant with environmental regulations.

Nitrogen Content

Nitrogen content of crude oils is also expressed as weight percent of oil. Basic nitrogen compounds are particularly undesirable in crude oil fractions, as they deactivate the acidic sites on catalysts used in conversion processes. Some nitrogen compounds are also corrosive. Crude oils with nitrogen contents greater than 0.25%wt need treatment in refineries for nitrogen removal.

Metals Content and Total Acid Number

Metals Content and Total Acid Number

Metals Content

Most common metals that are found in crude oil are included in organometallic compounds like nickel, vanadium iron and copper, ranging in concentration from a few ppm up to 1000 ppm by weight, depending on the source of crude oil. Similar to sulfur species, the metallic compounds tend to concentrate in the higher-boiling fraction of crude oil. Higher metal contents also require treatment during petroleum refining because of the corrosion activity of some metals and their tendency to accumulate on catalyst surfaces, thus deactivating the catalysts in a number of refinery processes. Metal content can be measured using a standard EPA Method 3040.

Total Acid Number

Acidity of crude oil is measured by titration with potassium hydroxide (KOH), using the standard method ASTM D664. The measured acidity is expressed as the Total Acid Number (TAN) that is equivalent to milligrams of KOH required to neutralize 1 gram of oil. This number is particularly important to control corrosion in the distillation columns through selection of corrosion-resistant alloys for surfaces that come into contact with oil.

Carbon Residue, Basic Sediment and Water, and Salt Content

Carbon Residue, Basic Sediment and Water, and Salt Content

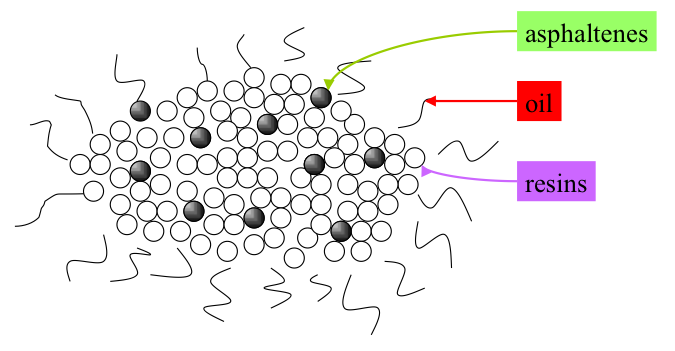

Carbon Residue

Carbon residue (as % wt of crude oil, or crude oil fraction) is determined as the weight of solid residue remaining after heating crude oil to coking temperatures (700-800°C). Two standard tests with slightly different procedures are used to measure carbon residue: ASTM D524 Ramsbottom Carbon Residue (RCR) and ASTM D189 Conradson Carbon Residue (CCR). Carbon residue relates to asphalt (or asphaltenes) content of oil and indicates the tendency of fouling in heater tubes and catalyst deactivation. The higher the carbon residue, the higher is the coking (fouling) propensity of crude oil.

Basic Sediment and Water (BS&W)

The standard method ASTM D4007 is used to measure the amount of suspended inorganic solid particles and water (BS&W) in crude oils. These contaminants are mixed with the oil during production, and high concentration of BS&W causes operational problems in a refinery.

Salt Content

Salt content of crude oils can be measured using the standard method ASTM D3230 and reported as lb NaCl/1000 bbl. Desalting (removing the salt) is necessary when NaCl content is greater than 10 lbs/1000 bbl. Such high salt contents lead to corrosion in distillation towers and other equipment.

Distillation and Boiling Points

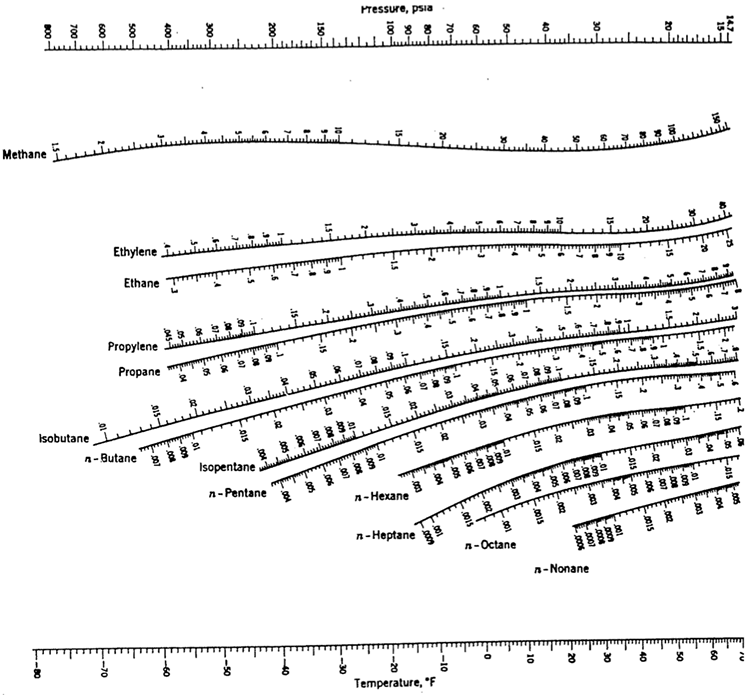

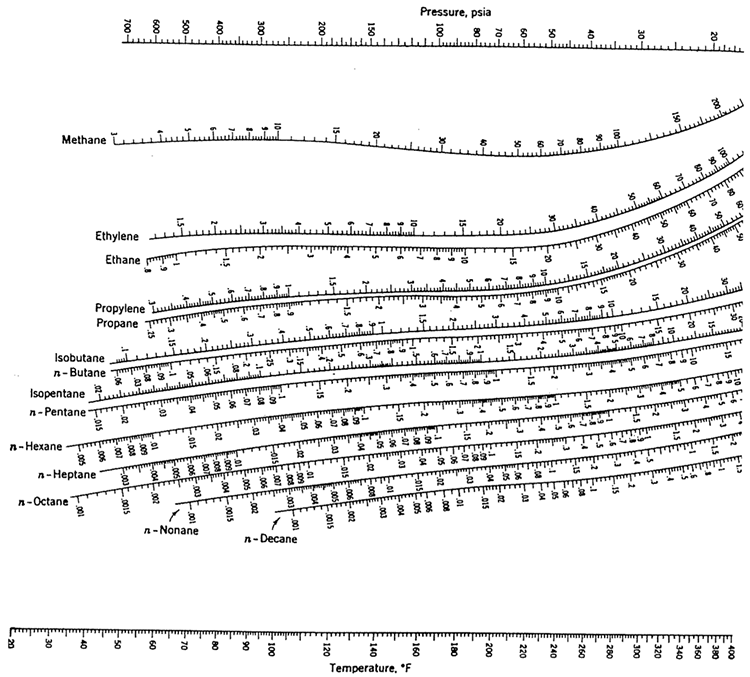

Distillation and Boiling Points

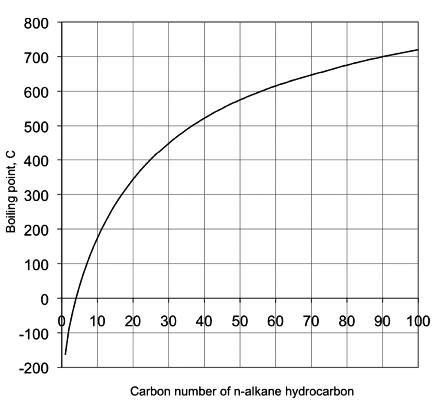

The boiling point of a pure compound in the liquid state is defined as the temperature at which the vapor pressure of the compound equals the atmospheric pressure or 1 atm. The boiling point of pure hydrocarbons depends on carbon number, molecular size, and the type of hydrocarbons (aliphatic, naphthenic, or aromatic) as discussed in Lesson 1. Figure 2.1 shows the boiling points of n-alkanes as a function of carbon number.

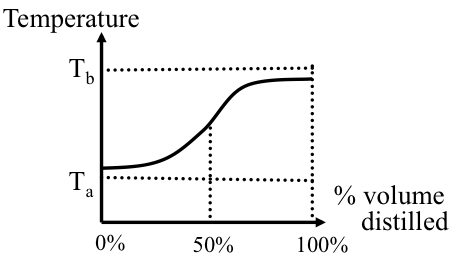

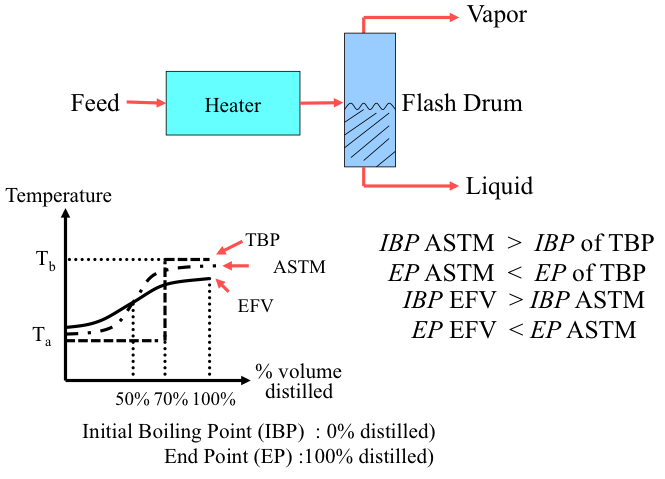

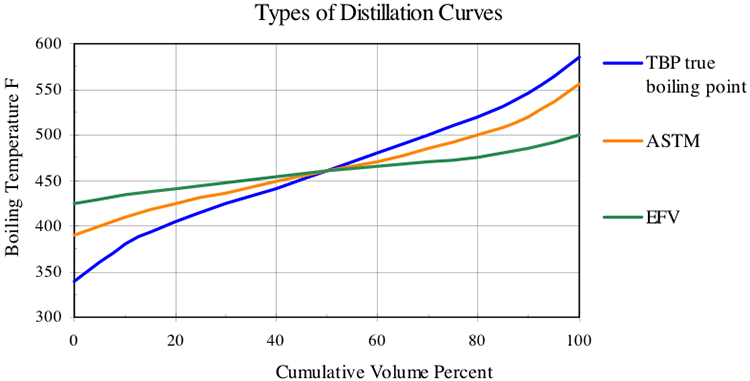

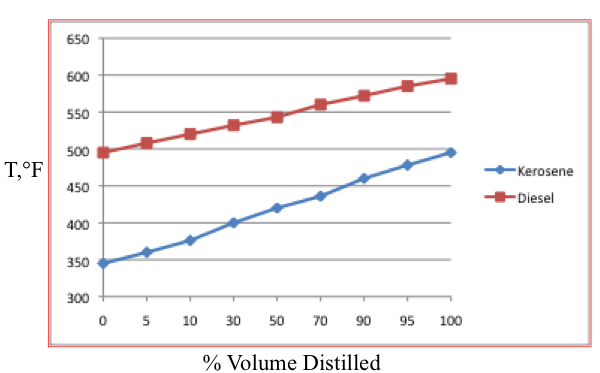

Complex mixtures such as crude oil, or petroleum products with thousands of different compounds, boil over a temperature range as opposed to having a single point for a pure compound. The boiling range covers a temperature interval from the initial boiling point (IBP), defined as the temperature at which the first drop of distillation product is obtained, to a final boiling point, or endpoint (EP) when the highest-boiling compounds evaporate. The boiling range for crude oil may exceed 1000 °F.

The ASTM D86 and D1160 standards describe a simple distillation method for measuring the boiling point distribution of crude oil and petroleum products. Using ASTM, D86 boiling points are measured at 10, 30, 50, 70, and 90 vol% distilled. The points are also frequently reported at 0%, 5%, and 95% distilled. ASTM D1160 is carried out at reduced pressure to distill the high-boiling components of crude oil. As an alternative method, distillation data can be obtained by gas chromatography (GC), in which boiling points are reported versus the weight percent of the sample vaporized. This test method described in ASTM D2887 is called simulated distillation (SimDis).

Average Boiling Points

Average Boiling Points

Average boiling points are useful in predicting physical properties and for characterization of complex hydrocarbon mixtures. The key here is to represent a mixture of compounds with a range of boiling points by a single characteristic boiling point. Since this is a formidable task, there are five different “average boiling points” that are used in different correlations. They are:

1, 2, and 3 can be defined for a mixture of n components as:

where ABP is is expressed as VABP, MABP, or WABP and xi is the corresponding volume, mole, or weight fraction of component i, and Tbi is the normal boiling point of component i. Cubic average boiling point (CABP) and Mean Average Boling Points (MeABP) can be calculated as follows.

For petroleum streams, volume, weight, or mole fractions of the components are not usually known. In this case, VABP is calculated from standard distillation (ASTM D86 Method) data, and empirical relationships (charts, or equations) are used to calculate the other average boiling points.

Here is the procedure:

Equation 1 (Ts are ASTM D86 temperatures for 10, 30, 50, 70, and 90% volume distilled, respectively):

Along with VABP, the slope of the ASTM D86, SL, is used for converting VABP to other average boiling points.

Equation 2:

The following empirical equations can, then, be used to obtain the temperature difference (ΔT) between VABP and other average boiling points (ABP) [2] :

Equation 3:

Equation 4:

Equation 5:

Equation 6:

and

Equation 7:

The temperature unit used for VABP, SL, and ΔT in these correlations is Kelvin.

The following script can be used to calculate VABP, MeABP by entering the distillation temperatures in the table.

You may also use the charts in Figure 4.1a and Figure 4.1b (p. 39) of your textbook [3] to obtain MeABP and MABP, respectively, from VABP. Note that the slope of the distillation curve used in those charts refers to True Boiling Point (TBP) distillation (not to ASTM distillation), and it is calculated as (T70% -T10%)/60.

[3] Petroleum Refining, by J. H. Gary, G. E. Handwerk, M. J. Kaiser, 5th Edition, CRC Press NY, 2007, Chapter 4, p.39.

Crude Assay

Crude Assay

Crude oil assay consists of a compilation of data on properties and composition of crude oils. The assay provides critical information on the suitability of crude oil for a particular refinery and estimating the desired product yields and quality. It also indicates how extensively a given crude oil should be treated in a refinery to produce fuels that are in compliance with environmental regulations. A typical crude assay should include the following major specifications:

- API Gravity

- Total Sulfur (% wt)

- Pour Point (°C)

- Viscosity @ 20°C (cSt)

- Viscosity @ 40°C (cSt)

- Nickel (ppm)

- Vanadium (ppm)

- Total Nitrogen (ppm)

- Total Acid Number (mgKOH/g)

- Distillation Data

- Characterization factor KUOP, KW

Characterization Factors

Characterization Factors

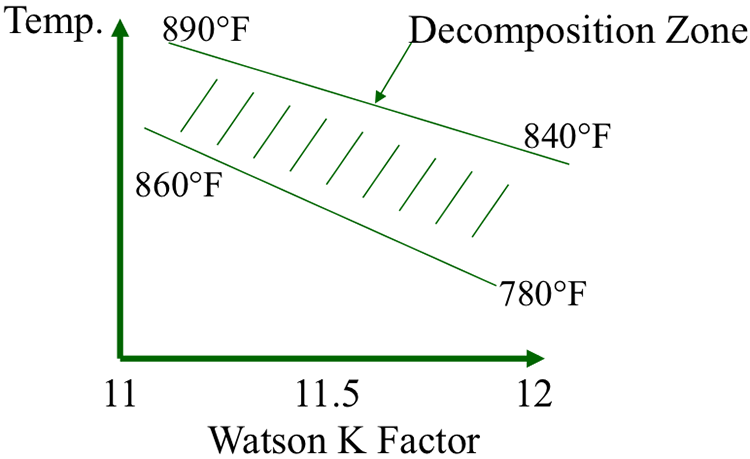

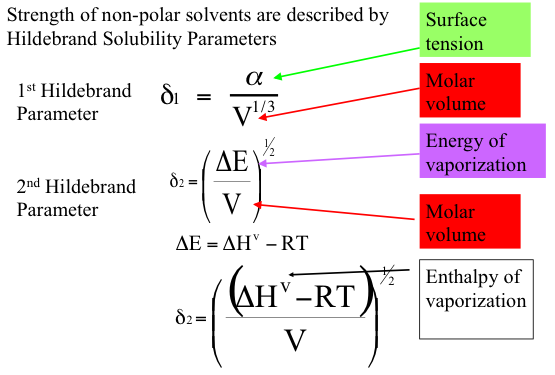

Since the early days of the petroleum industry, some physical properties of crude oil were used to define characterization factors for classification of crude oil with respect to hydrocarbon types [4] as shown in Equation 8.

where: Tb = volume, or mean average normal boiling point in R (degree Rankine) and SG = specific gravity at 15.6°C (60°F). To calculate KUOP or KW, volume average boiling point (VABP) or mean average boiling point is used, respectively. Depending on the value of the Watson characterization factor, crude oils are classified as paraffinic (Kw = 11-12.9), naphthenic (Kw =10-11), or aromatic (Kw <10).

UOP or Watson Characterization Factor

SG: Specific Gravity at 15ºC (60ºF)

Tb: average boiling point (ºR)

KUOP, or Watson = (Tb)1/3/SG15ºC(60ºF)

KUOP uses Volume Average Boiling Point (VAPB)

TVABP = (T10% + T30% + T50% + T70% + T90%)/5

Tv% = ASTM Distillation T at 10%, 30%, 50%, 70% and 90% distilled Volume

KWatson uses Mean Average Boiling Point (MeAPB)

Another parameter defined in the early years of petroleum characterization is the viscosity gravity constant (VGC). This parameter depends on viscosity expressed in Saybolt Universal Seconds (SUS) and specific gravity. According to a standard method (ASTM D2501), VGC can be calculated at a reference temperature of 100°F as follows in Equation 9:

where V(100°F) is the viscosity in SUS and SG is the specific gravity at 15.6°C (60°F). VGC varies between 0.74 to 0.75 for paraffinic, 0.89 and 0,94 for naphthenic, and 0.95 and 1.13 for aromatic hydrocarbons.

The U.S. Bureau of Mines Correlation Index (BMCI) or (CI) is useful for characterization of crude oil fractions. CI is defined in terms of Mean Average Boiling Point (Tb) and specific gravity (SG) at 60°F as shown in Equation 10:

According to this CI scale, all n-paraffins have a CI value of 0, while cyclohexane (the simplest naphthene), has a CI value of 50, and benzene has a CI value of 100. Using the CI values, crude oils can be classified as follows:

| paraffinic | CI<29.8 |

|---|---|

| naphthenic | CI<57.0 |

| aromatic | CI>75.0 |

[4] K. M. Watson, E. F. Nelson , George B. Murphy, “Characterization of Petroleum Fractions,” Ind. Eng. Chem., 1935, 27 (12), pp 1460–1464

Elemental Analysis and Ternary Classification of Crude Oils

Elemental Analysis and Ternary Classification of Crude Oils

Despite a wide variety of crude oil found in different parts of the earth, the elemental composition of most crude oils changes in narrow ranges, as shown in Table 2.2.

| Element | % Wt |

|---|---|

| C | 84-86% |

| H | 11-14% |

| S | 0-6% |

| N | 0-1% |

| O | 0-2% |

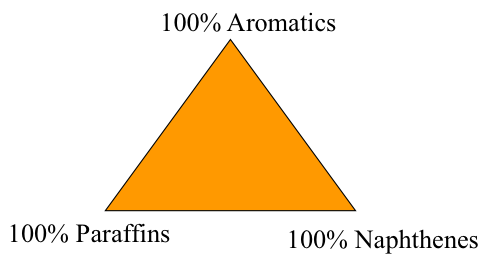

With such narrow ranges of change in elemental contents, elemental composition does not have much utility for classification of crude oil. Instead, variations in hydrocarbon composition (paraffins, naphthenes, and aromatics) are used to classify crude oils, using a ternary diagram, shown in Figure 2.2. Each apex of the triangle represents 100 percent weight of the corresponding compounds, and 0% of this particular type of hydrocarbons on the side of the triangle across from the apex. For example, the side at the bottom of the triangle (across from the apex of 100% aromatics) represents binary mixtures of paraffins and naphthenes.

If you need to refresh your memory on reading ternary diagrams, you may check "Reading a Ternary Diagram [11]", or consult other sources. The list below shows the six classes of crude oil that are defined using a ternary diagram. These classes are shown as areas on the ternary diagram for paraffins, below. It is generally accepted that Class 1 (rich in paraffins) represents the most desirable type of crude oil because refining these crudes would readily lead to high yields of light and middle distillates that constitute the fuels such as gasoline, diesel fuel, and jet fuel which are in high demand. Extensive refining would be required to produce high yields of distillate fuels from aromatic crudes (e.g., Class 4-6). Class 1 crudes tend to have high °API and low sulfur contents and tend to be more expensive than the other types of crude oils.

Ternary Classification of Crude Oils

- Paraffinic Crudes

paraffins + naphthenes > 50%

paraffins > naphthenes

paraffins > 40% - Naphthenic Crudes

paraffins +naphthenes > 50%

naphthenes > paraffins

naphthenes > 40% - Paraffinic-Naphthenic Crudes

Aromatics < 50%

paraffins < 40%

naphthenes < 40% - Aromatic-Naphthenic Crudes

Aromatics > 50%

naphthenes > 25%

paraffins < 10% - Aromatic-Intermediate Crudes

Aromatic > 50%

paraffins > 10% - Aromatic-Asphaltic Crudes

Naphthenes < 25%

paraffins < 10%

Video: Lesson 2 Paraffins (2:47)

Ternary diagrams could be very useful tools for classifying crude oils. Here you see a ternary diagram, a triangle in essence. On the corners of the triangles, we can see pure hydrocarbons. At the top, where you see 100% aromatics, that is just one point at the top represents pure aromatic compounds.

On the left-hand side at the bottom, 100% paraffins point on the corner, and on the right, 100% naphthenes. The lines that connect these points represent binary mixtures. For example, if you connect aromatics corner with the paraffins on that line, you will only have aromatics and paraffins.

As an example, let us define the region in this ternary diagram for the group 1 or classification 1 crude oils that are paraffin liquid oils. You see the horizontal line with an arrow pointing downward. So below that line, the contents of paraffins and naphthenes is greater than 50%. Above that line, obviously, aromatics are greater than 50%.

Now, establish the second boundary line for the group 1 crude oils. That is paraffinic crude oils. You see the vertical line right in the middle of the triangle separating the triangle into two areas. To the left of that vertical line, we will have paraffins contents greater than naphthenes everywhere to the left of this point.

So with these two boundary lines then, one horizontal, one vertical, we have established a region where the contents of paraffins and naphthenes are greater than 50%, and paraffin contents are greater than naphthenes.

To establish the region for the type 1 crude oils, we need the third boundary line. So you see here the line that is designating paraffin contents greater than 40%. So to the left of that line in the triangle, the paraffin contents is greater than 40%. So all these three lines then designate the group 1 or type 1 crude oil or region in the ternary diagram that is the paraffinic crude oils region.

Video: Lesson 2 Aromatics (2:34)

Let us continue with demonstration of using ternary diagrams for crude classification. This time, we will place the type 4 aromatic-naphthenic crudes on the ternary diagram. You'll see the boundaries for this type of crude. That is, aromatics greater than 50%, naphthenes greater than 25%, paraffins less than 10% in type 4 crude oils.

See the horizontal line right in the middle of the triangle, which designates the first boundary? That's aromatics greater than 50%. So above that line, in the orange region in the triangle, the aromatic content is greater than 50%. That is the first boundary.

The second boundary line defines an area where naphthenes are greater than 25%. You see the line on the triangle to the right of that line? [? Everywhere ?] is naphthenes greater than 25%. With these two boundary lines now, aromatics greater than 50% and naphthenes greater than 25%, we are confined to that little triangle, the orange triangle in the ternary diagram.

Now we need to place the third boundary line. The third boundary line for this type is paraffins less than 10%. You see the gray shaded region, which is essentially type 4 aromatic-naphthenic crudes region, as we have established.

We can now identify the region for group 5 crude oils. That is aromatic-intermediate crudes. That is bound by two lines.

So you can see the purple region, purple triangle, bounded by paraffins greater than 10% and aromatics greater than 50%. This is number 5 type aromatic-intermediate crudes. With these boundary lines, we can now identify the region for type 6 aromatic-asphaltic crudes. So you can see the orange region which is bound by naphthenes less than 25% and paraffins less than 10%.

Self-Check Questions

Self-Check Questions

Take a few minutes to answer the questions below. When you are ready, Click Check to see the solutions.

Assignments

Assignment Reminder

Each week, you will have a number of assignments. This week's assignments are listed below. All assignments are submitted in Canvas. For due dates, please check your syllabus.

- Quiz 1 is due next Monday. Quiz 1 will cover material in both Lessons 1 and 2.

- Exercise 1 is due this week. Read the instructions carefully on what is acceptable.

Quiz 1

Quiz 1 is located in the Quizzes folder in Canvas. Quiz 1 will cover material in Lessons 1 and 2.

Exercise 1

Exercise 1 Instructions

Exercise 1 is provided in Canvas module Lesson 2 as a downloadable file. Submit your answers as a file in PDF format the Exercise 1 assignment in the Lesson 2 Module. For all the exerciase in this course, please make sure that you clearly indicate all the steps that you use to solve the problems and submit your own work.

Please note:

Scans of handwritten pages are not acceptable.

Summary and Final Tasks

Lesson 2 Summary

Selected properties of crude oil provide information on its quality and the conditions for optimum operation of a petroleum refinery for processing the crude oil to produce the desired fuels. Readily measurable physical properties of crude oil (such as density, boiling point, and viscosity) not only help predict the physical behavior of crude oil during refining but also give insight into the chemical composition of the oil. Therefore, physical properties can be used in developing characterization factors that relate to the chemical behavior of crude oil and the characteristics of the resulting refinery products. In addition to using characterization factors, crude oils are classified using ternary diagrams reflecting the hydrocarbon composition in terms of paraffins, naphthenes, and aromatics.

Learning Outcomes

By the end of this lesson, you should be able to:

- define the significant properties of crude oil, including density, viscosity, average boiling point, sulfur, and salt content;

- understand the significance of crude oil properties in terms of refinery objectives, and describe crude oil assay;

- define and interpret the classification factors (Watson, UOP, VGC, and BMCI) as they relate to the hydrocarbon composition of crude oils;

- calculate average boiling points for crude oils using different averaging techniques, and differentiate Watson and UOP characterization factors;

- analyze the elemental composition of crude oils and outline ternary classification of crude oils with respect to hydrocarbon composition, i.e., aromatics, paraffins, and naphthenes;

- assess the use of ternary classification of crude oils to estimate the refinery product yields.

Reminder - Complete all of the Lesson 2 tasks!

You have reached the end of Lesson 2! Double-check the to-do list below to make sure you have completed all of the activities listed there before you begin Lesson 3. Please refer to the Course Syllabus for specific time frames and due dates. Specific directions for the assignment below can be found within this lesson.

| Readings | J. H. Gary, G. E. Handwerk, Mark J. Kaiser, Chapter 3, pp. 57-61, 65-70 and the course material from this site |

|---|---|

| Assignments | Exercise 1 - Submit to the Exercise 1 Assignment in the Lesson 2 Module.

|

Questions?

If you have any questions, please post them to our Help Discussion Forum (not email), located in Canvas. I will check that discussion forum daily to respond. While you are there, feel free to post your own responses if you, too, are able to help out a classmate.

Lesson 3: Overall Refinery Flow

Lesson 3 Overview

Overview

Video: FSC 432 Lesson 3 (2:16)

In lesson three, we will take a quick walk through a refinery, and go through some different kinds of processes. There are four types of processes at a petroleum refinery. They are separation processes, which are essentially physical processes. No chemical change takes place in these processes, just physical separation.

The second category is conversion processes, where there's a lot of chemistry that's involved. We are breaking and making new chemical bonds, so that we could produce the fuels in quantities that we want, in the yields that we want.

The third kind of process is the finishing process, which is really to make sure that any product leaving the refinery is compliant with performance specifications as well as environmental regulations.

And the fourth kind of process is supporting process, and these are essential processes to make sure that whole refinery functions, and all these processes actually do perform their function, in essence, or their objectives.

Now, as we go through this refinery, we will see that there are certain areas of focus. Most recently, the refineries have focused on upgrading heavy oil. When we say heavy, we really refer to the density-- high-density crude oil.

High-density crude oil typically has a high aromatic hydrocarbon content, and these crudes are difficult to process, more expensive to process. So we will talk about some basic strategies-- how one could upgrade these heavy, highly aromatic crude oils into the desirable products, which tend to be lighter. That means lower density, such as gasoline, diesel, and jet fuel.

Overview

Selected properties of crude oil provide information on its quality and the conditions for the optimum operation of a petroleum refinery for processing the crude oil to produce the desired fuels. Readily measurable physical properties of crude oil (such as density, boiling point, and viscosity) not only help in predicting the physical behavior of crude oil during refinery but also give insight into the chemical composition of the oil. Therefore, physical properties can be used in developing characterization factors that relate to the chemical behavior of crude oil and the characteristics of the resulting refinery products. In addition to using characterization factors, crude oils are classified using ternary diagrams reflecting the hydrocarbon composition in terms of paraffins, naphthenes, and aromatics.

As introduced in Lesson 1, petroleum refining integrates four types of processes: separation, conversion, finishing, and supporting processes. This lesson involves a quick walk through a simple refinery in the U.S. to see what happens to a barrel of crude oil, and to provide more detail on how different processes are sequenced for optimum operation. The simple animation below shows a simplified diagram of processing network to maximize gasoline yield and produce the other distillate fuels (jet fuel, diesel fuel, and fuel oil) in high yield.

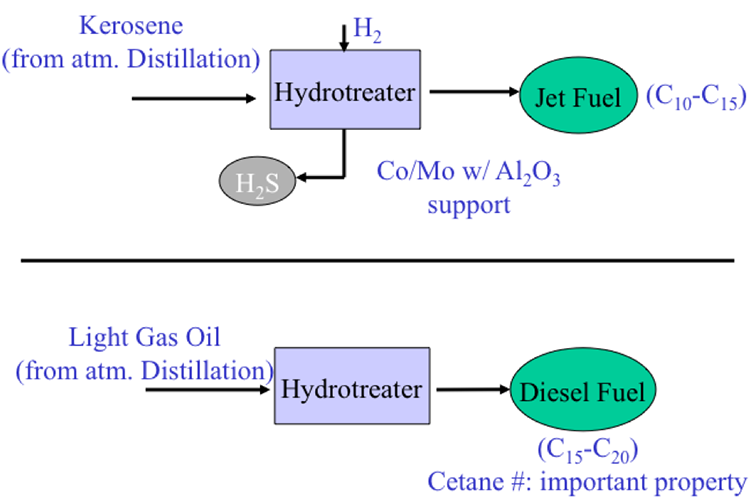

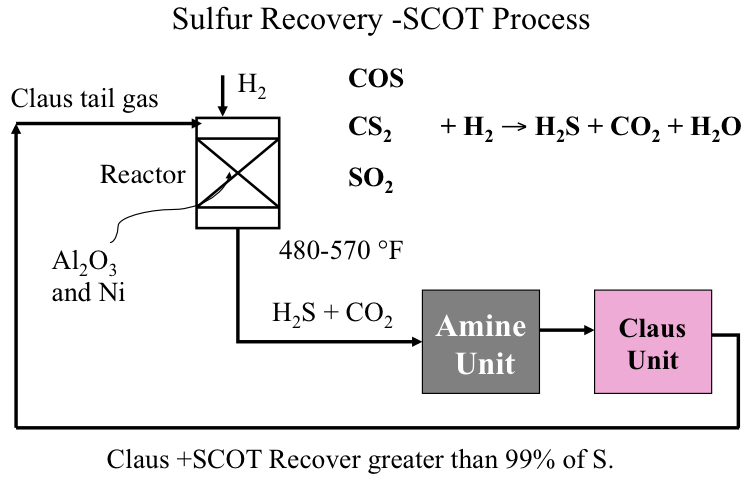

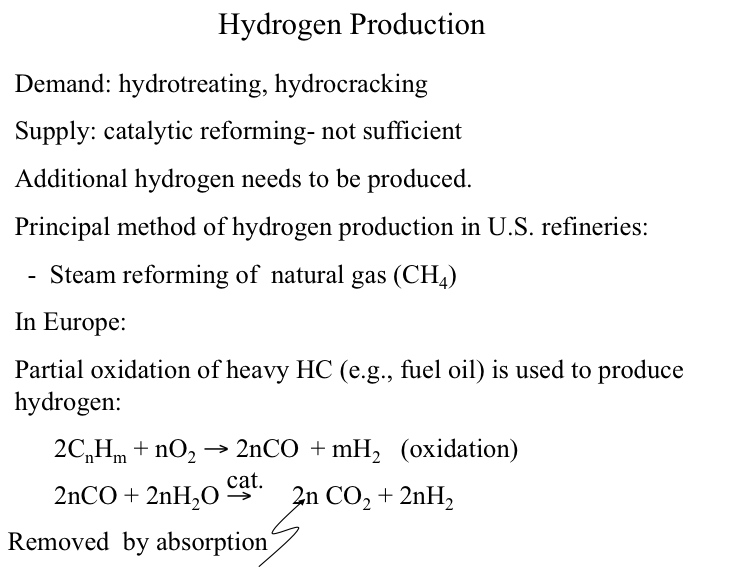

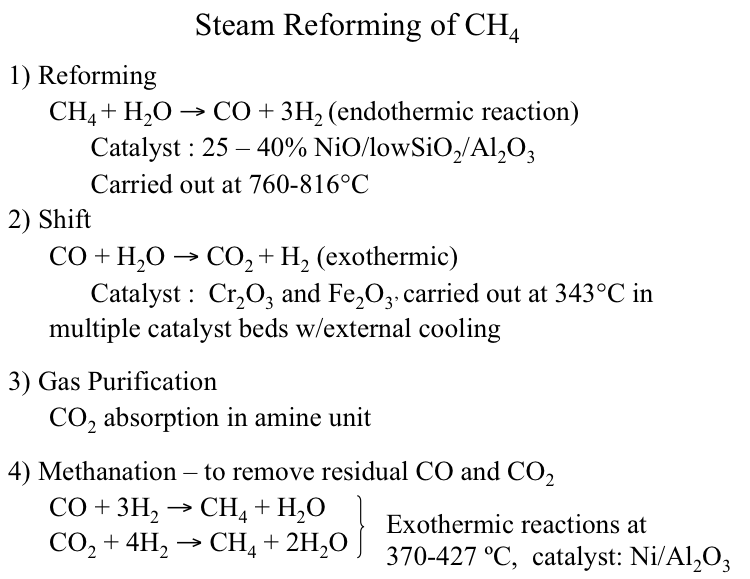

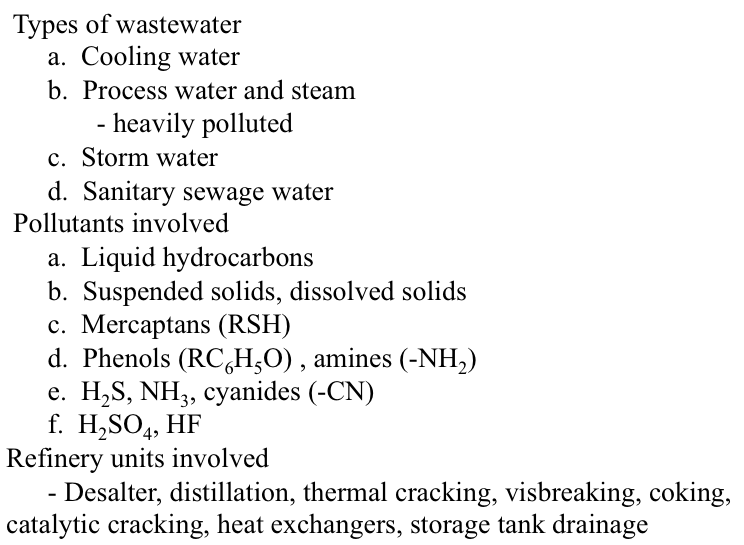

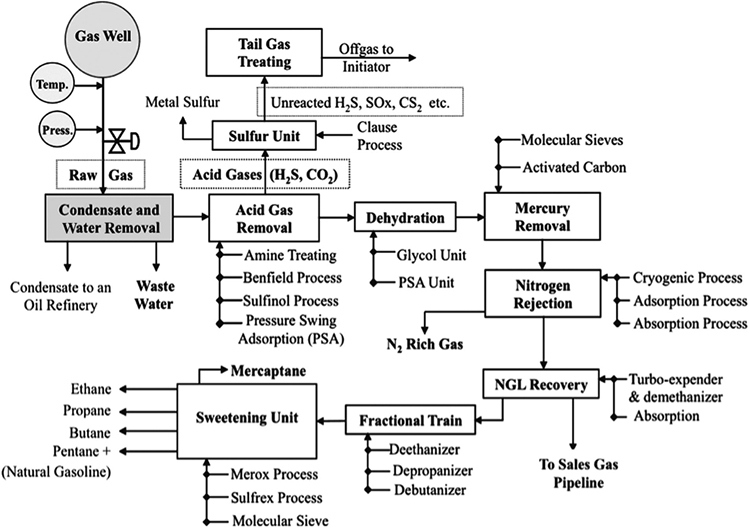

The first sequence of processes in a refinery makes use of physical separation to wash the salt out and to fractionate the desalted crude into different boiling ranges in a distillation column. Following the distillation, these fractions are subjected to further separation processes, such as those in Light Ends Unit (LEU) dewaxing and deasphalting units; to finishing processes, such as hydrotreatment; and to conversion processes, such as catalytic cracking, hydrocracking, visbreaking, and delayed coking. As shown in the animation below, the final products from these processes include Liquefied Petroleum Gas (LPG), lubricating oil base stock, asphalt, jet fuel and diesel fuel, gasoline, fuel oil, and petroleum coke. Some fractions from LEU are sent to finishing processes (blending and hydrotreatment) and further to a conversion process (reforming) to produce additional gasoline. Light products from catalytic cracking are subjected to further conversion in the alkylation process to produce more gasoline. Finally, supporting processes, hydrogen production and sulfur recovery, help remove the major heteroatom contaminant, sulfur, from the petroleum fuels through hydrotreatment [1].

This refinery scheme is typical in U.S. refineries where the premium product is gasoline, as one could tell from the number of processes that lead to gasoline as the major product. The gasoline streams from different processes are blended in sophisticated linear and non-linear programming schemes to produce the three grades of gasoline sold in the U.S., regular, intermediate, and premium grades defined in reference to octane number. Elsewhere in the world, there is more emphasis on producing diesel fuel rather than gasoline, since the transportation systems are not as heavily dependent on gasoline-powered passenger vehicles. Diesel fuel is preferred for mass transport options (e.g., buses and trains), as diesel engines (with compression-ignition) can deliver more power than spark-ignition gasoline engines.

In the following sections, each major process group in a refinery network will be introduced in sequence. We will discuss how they fit in the “industrial ecology” of petroleum refining for the overall economic goal of maximizing profit in the prevailing markets for crude oil and the refined petroleum products. The video below presents a flow diagram integrating the four types of processes in a petroleum refinery.

Video: FSC 432 Simple Refinery Flow (4:36)

PRESENTER: Here we will go over a very simple refinery flow. This is a much simpler scheme than we have included in lesson one for different types of refinery processes, separation, finishing, convergence, and support. Here what we would like to do is to connect crude oil feed to these major refinery products starting with LPG, the lightest, gasoline, jet fuel, fuel oil, asphalt, and coke.

One point to make, look at the number of arrows that go to gasoline, which really shows the significance of this product as the major product in US refineries, the gasoline. Quite a few different processes produce gasoline. Of course jet fuel and diesel also are important refinery products.

So let's look at the processes that we can use to connect crude oil to these major products. Here again crude oil goes through desalting and distillation. And through the light ends unit separations we produce the first product, LPG, or liquefied petroleum gas. That is essentially propane and butane.

The light straight-run naphtha coming from the light ends unit go through blending to the gasoline pool. And from the atmospheric distillation unit, kerosene and light gas oil go through hydrotreatment treatment to produce jet fuel and diesel. So you can see here that using just separation and finishing processes we could produce LPG straight from gasoline, which would be low octane number, and jet fuel and diesel without any convergent process.

We bring in two additional separation processes, dewaxing and deasphalting. You would remember dewaxing would produce the lubricating oil base stock and the wax byproduct. And deasphalting, treating the vacuum distillation resid would separate out asphalt and produce deasphalted oil for further conversion.

So we have pretty much exhausted our separation process. You can see there are still quite a few arrows pointing nowhere. So we need to go to our conversion processes to connect to our final products.

Here are our conversion processes in color purple. Starting from the left, hydrocracking treats the heavy vacuum gas oil to make additional jet fuel and diesel. Visbreaking takes the VDR from the vacuum distillation process and produces fuel oil.

Moving to the right, catalytic cracking takes the feed from the distillation unit-- could be a light gas oil or a heavy gas oil-- to produce gasoline. This is the major gasoline production path. And the byproducts from cat cracking goes through alkylation to make additional gasoline, high octane number gasoline.

And the heavy naphtha, straight heavy naphtha coming from the light ends unit through hydrotreatment goes through reforming to make another high octane gasoline stream. And finally the VDR from the vacuum distillation could go through coking to make additional gasoline, as well as the byproduct coke.

Finally, we will use the two major supporting processes, hydrogen production and sulfur recovery, to connect all the arrows. You know that hydrogen is used to remove sulfur in the crude oil fractions as hydrogen sulfide. And hydrogen sulfide is converted to elemental sulfur in the sulfur recovery unit. And elemental sulfur is sold as a refinery product. So that completes our simple refinery flow.

Learning Outcomes

By the end of this lesson, you should be able to:

- illustrate the refinery processes with examples for each category of processes;

- distinguish and evaluate the functions of different refinery processes to control refinery product yield and composition;

- evaluate the principles behind the major refinery processes and examine the products from each process from Distillation to Hydrocracking;

- formulate strategies for upgrading heavy oil.

What is due for Lesson 3?

This lesson will take us one week to complete. Please refer to the Course Syllabus for specific time frames and due dates. Specific directions for the assignments below can be found on the Assignments page within this lesson.

| Readings: | J. H. Gary, G. E. Handwerk, & Mark J. Kaiser, Chapter 1, pp. 32-36; Chapter 2, pp. 41-55 and the course material from this site |

|---|---|

| Assignments: | Exercise 2: Using ternary classification to characterize crude oil blends |

Questions?

If you have any questions, please post them to our Help Discussion (not email), located in Canvas. I will check that discussion forum daily to respond. While you are there, feel free to post your own responses if you, too, are able to help out a classmate.

Desalting and Distillation

Desalting and Distillation

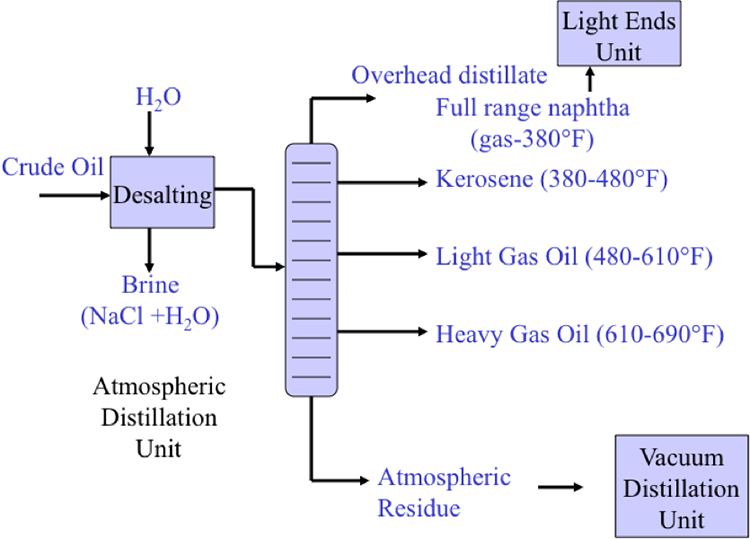

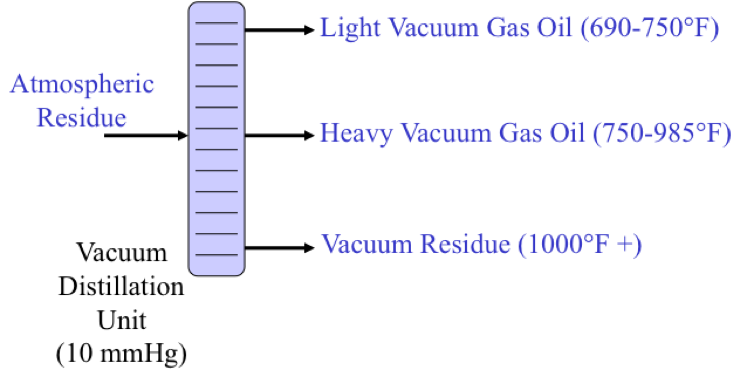

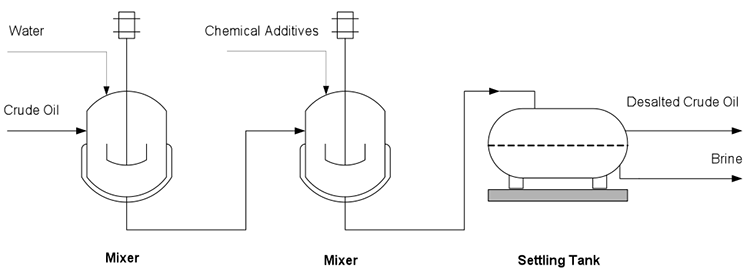

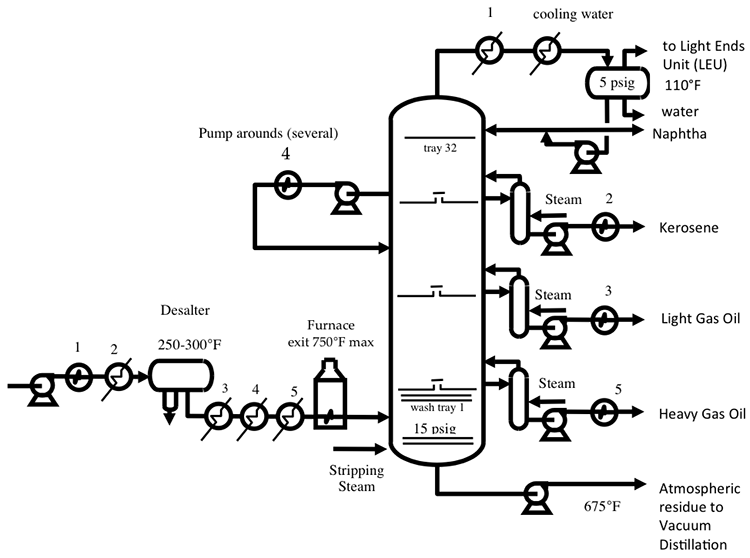

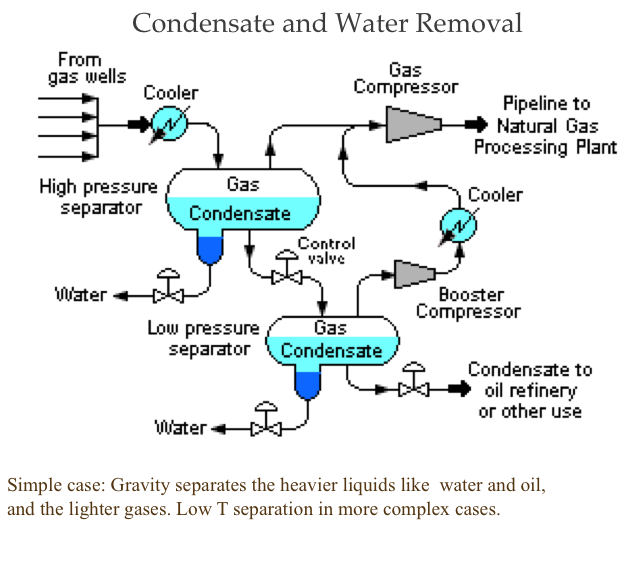

Although distillation is usually known as the first process in petroleum refineries, in many cases, desalting should take place before distillation (Figure 3.1). Salt dissolved in water (brine) enters the crude stream as a contaminant during the production or transportation of oil to refineries. If salt is not removed from crude oil, serious damage can result, especially in the heater tubes, due to corrosion caused by the presence of Cl. Salt in crude oil also causes reduction in heat transfer rates in heat exchangers and furnaces.

The three stages of desalting are:

- adding dilution water to crude;

- mixing dilution water with crude by a mixer;

- dehydration of crude in a settling tank to separate crude and sediment and water (S&W).

Desalting and fractional distillation of crude oil schematic:

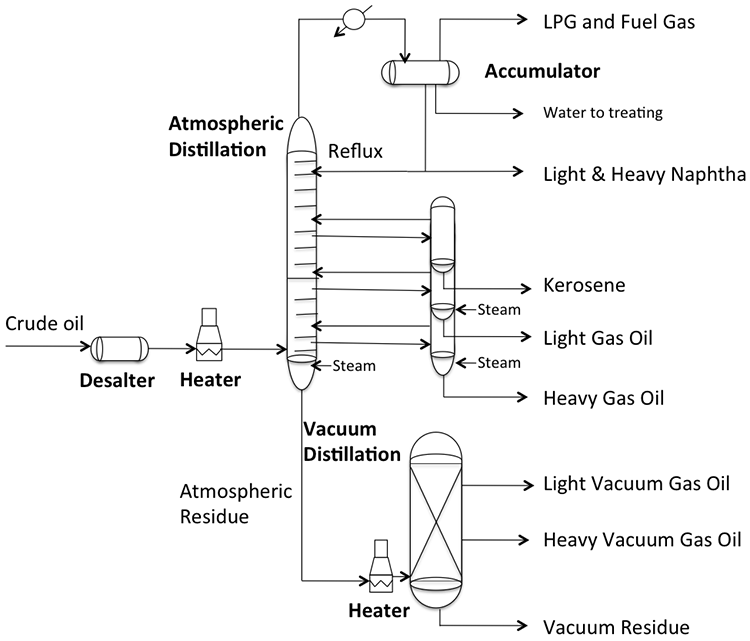

Crude oil enters an atmospheric distillation unit and starts at desalting. Crude oil and water are added and a brine of NaCl + H20 comes out. The resulting oil is separated into overhead distillate & full-range naphtha (gas-380ºF) [this goes to a light ends unit], Kerosene (380-480ºF), Light Gas oil (480*-610ºF), Heavy Gas Oil (610-690ºF), & Atmospheric Residue.

Atmospheric Residue goes to a vacuum distillation unit (10mmHg) which separates the residue into light vacuum gas oil (690-750ºF), Heavy Vacuum Gas Oil (750-985ºF), Vacuum Reside (1000ºF +)

Desalting can be performed in a single-stage or two-stage units. The amount of water wash and the temperature of the mixing process depends mainly on the crude API gravity [2].

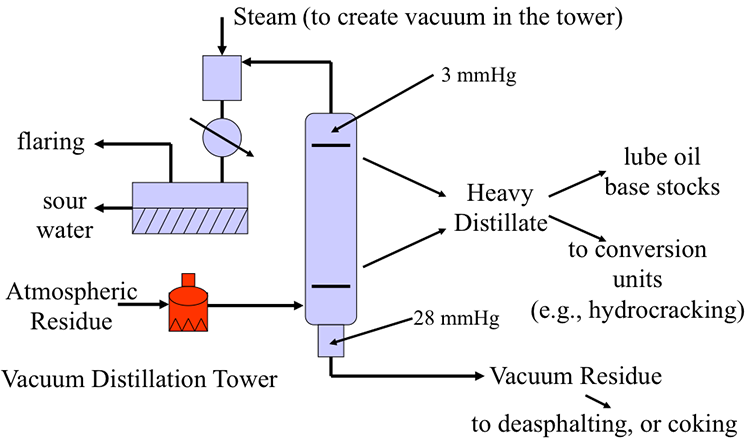

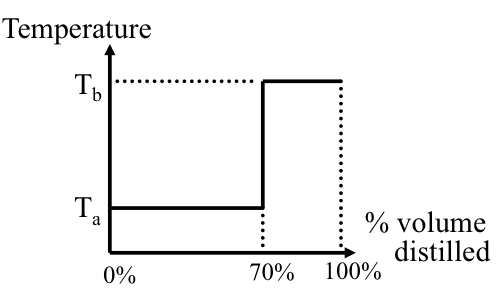

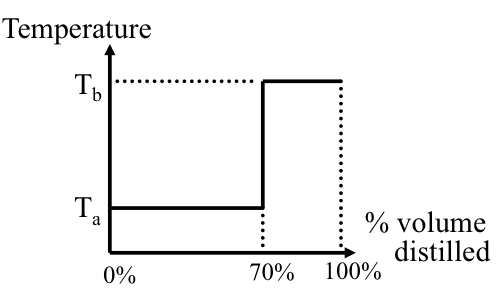

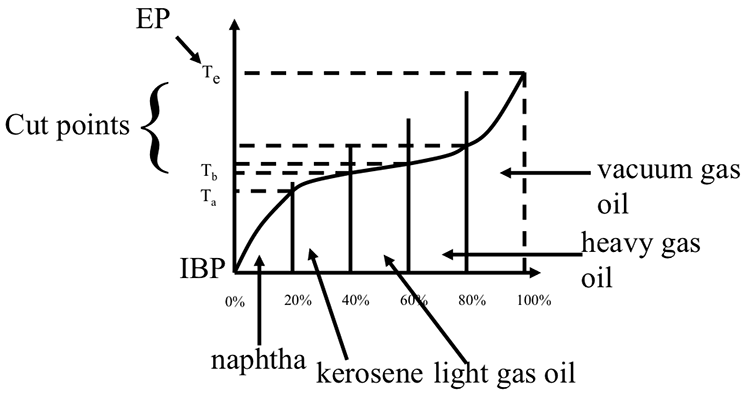

Distillation separates hydrocarbon compounds into distillate fractions based on their boiling points or volatility. More volatile compounds (with low boiling points) tend to vaporize more readily than heavy compounds, and this forms the basis of separation through distillation. In a distillation column, light components are removed from the top of the column, and the heavier part of the mixture appears in the bottom. For a crude that is a mixture of thousands of hydrocarbons, some very light compounds such as ethane and propane only appear in the top product, while extremely heavy and non-volatile compounds such as asphalts only appear in the bottom. Figure 2 shows a simple diagram of atmospheric and vacuum distillation units and the fractional separation of the crude oil into different boiling fractions with the indicated boiling ranges. The lightest compounds found in crude oil come out from the top of the distillation column (referred to as overhead distillate, or full-range naphtha) and are sent to the Light Ends Unit (LEU) for further separation into LPG and naphtha, as discussed later. The side streams separated in the atmospheric distillation column give fractions that include the “straight-run” products called kerosene, and light and heavy gas oils. The residue from the atmospheric distillation column generates two side streams, light and heavy vacuum gas oils, and vacuum residue from the bottom. All of these distillation products are subjected to subsequent processing to produce light and middle distillate fuels and non-fuel products, as described in the following sections, starting with LEU.

Light Ends Unit

Light Ends Unit

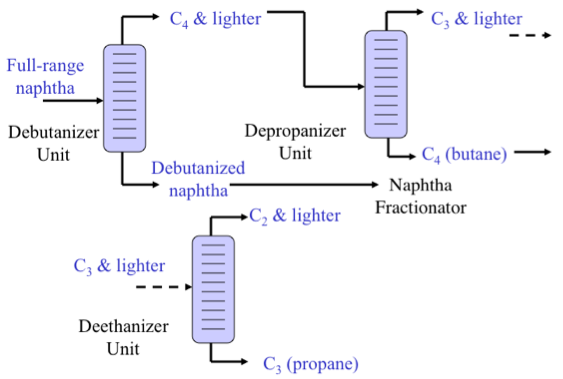

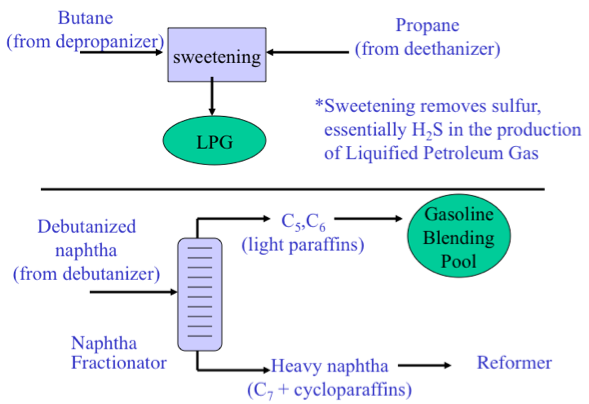

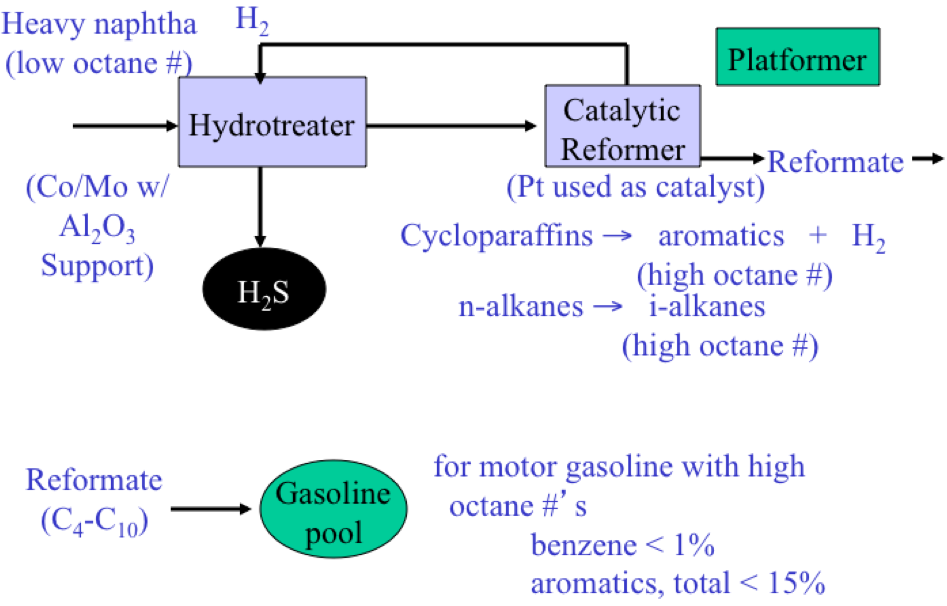

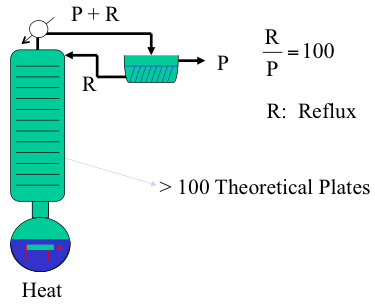

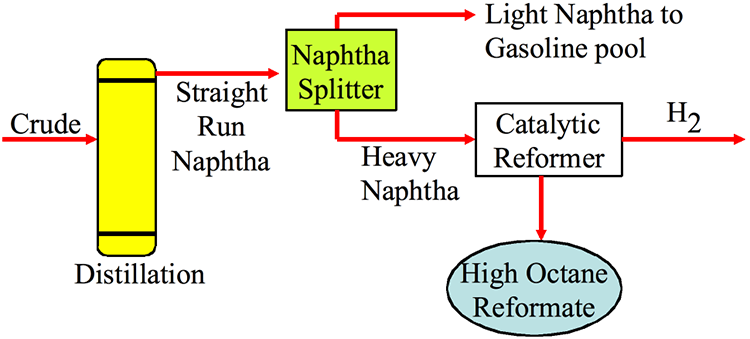

As shown in Figure 3.2, the Light Ends Unit consists of a sequence of distillation processes to separate the overhead distillate product from the atmospheric distillation column into five streams consisting of methane and ethane (C2 and lighter), to propane (C3), butane (C4), light naphtha, and heavy naphtha. The fraction C2 and lighter is used as fuel gas in the refinery to provide heat or generate steam. Propane and butane are sold as liquefied petroleum gas (LPG) after removing H2S. Light naphtha fraction that consists of C5 and C6 paraffins (pentane and hexane) is sent to the gasoline blending pool as straight-run gasoline, while the heavy naphtha fraction (rich in cycloalkanes, or naphthenes) is sent to a catalytic reforming process to produce gasoline with a high octane number.

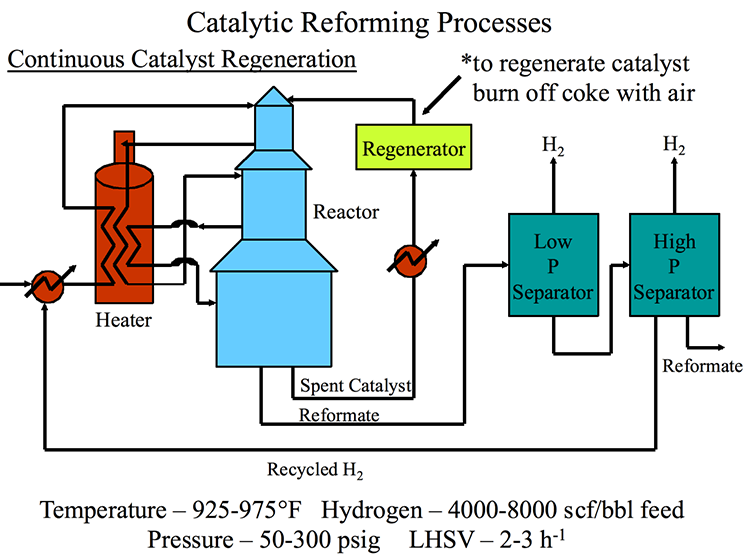

Catalytic Reformer

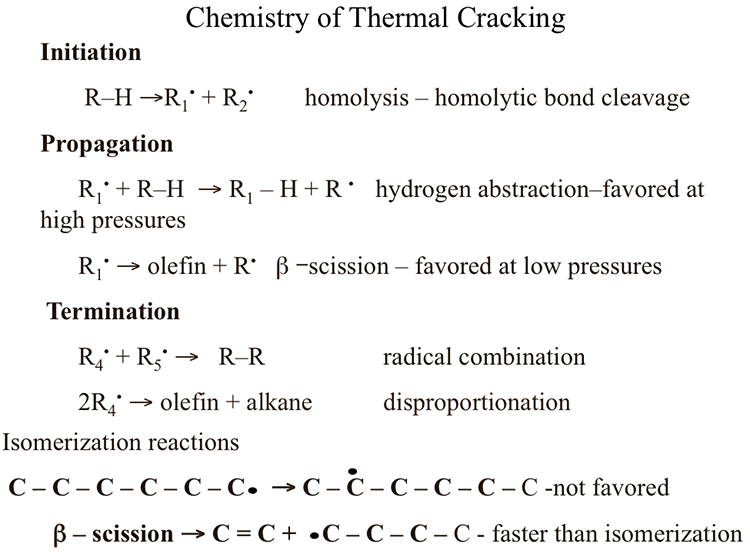

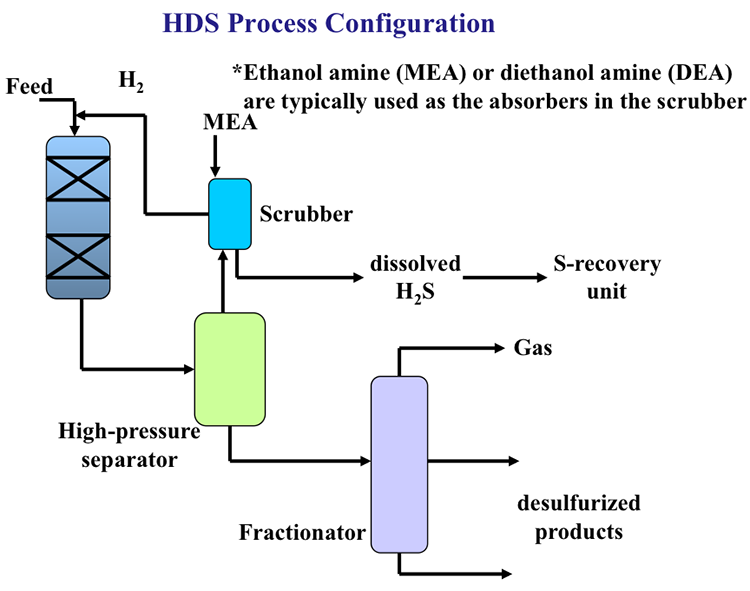

Catalytic Reformer