5.1.2c: Hoists, Hydraulic Transport, and Belt Conveyors

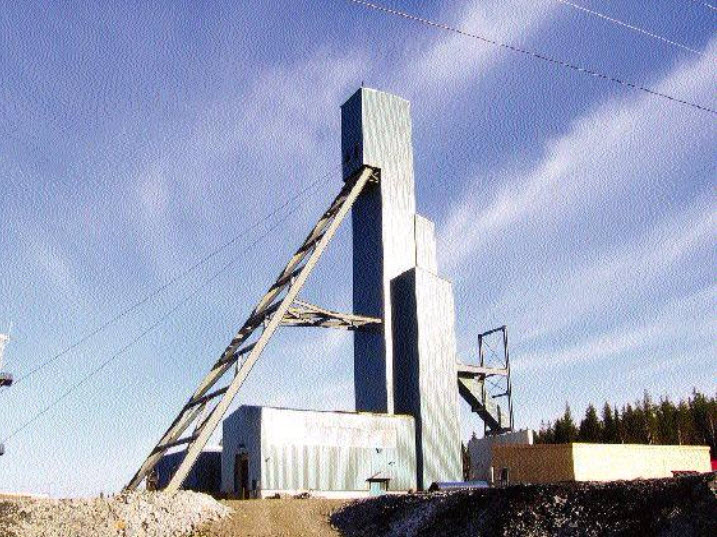

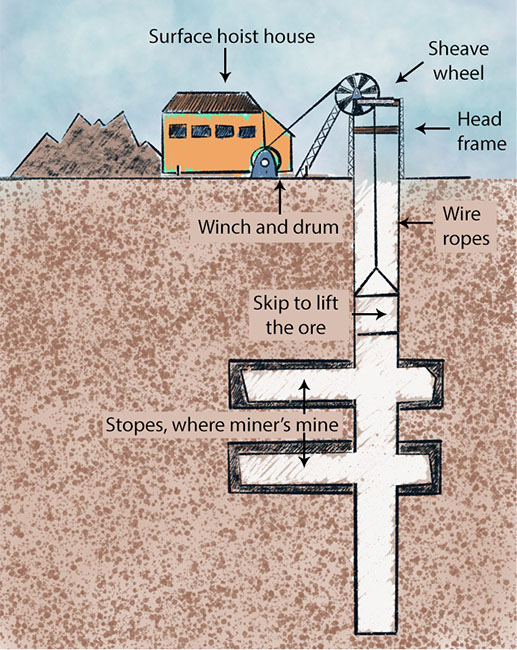

Deep underground mines may be accessible only through a shaft that is sunk from the surface to the working levels of the mine. Not only will all workers and supplies access the mine through the shaft, but also all ore will have to come out of the shaft. This is accomplished by hoisting systems. Three major components of a hoist are the skip, which holds the ore and is attached to the winder on the surface by wire ropes, the headframe and the hoist winder (winch and drum). The headframe supports the sheave wheel over which the wire rope is connected to the skip. As the drums in the surface hoist house wind the rope onto the drum, the skip is pulled to the surface, where it is dumped.

The winder is shown in the first picture below, the bottom headframe in the second, and the bottom dump skip in the third. Often a different type of hoist from the one shown is used, which allows a skip to be connected at the bottom and the top of the shaft so that as the one is being unloaded, the other is being loaded. A skip typically holds up to 50 yd3 of material.

Hydraulic Transport

Hydraulic transport, often known as a slurry transport system, is used in limited circumstances. The ore is mixed with a fluid, e.g., water, and pumped from the mine to the processing plant. It is an energy-intensive system and is best suited to a limited class of ores such as phosphate, which is already mixed with water in the mining process, or other ores obtained from hydraulicking or dredging. The system is straightforward, consisting of high horsepower slurry pumps every few miles and a large diameter pipe, greater than 2’ in diameter.

Belt Conveyors

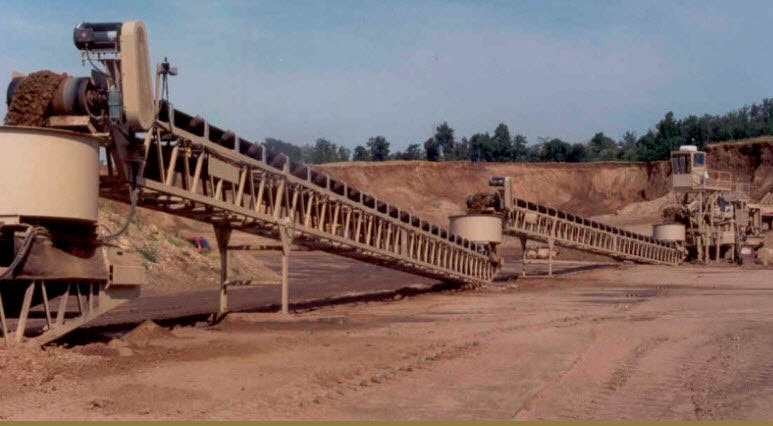

Belt conveyors are the workhorses of modern mines, both surface and underground. The belt conveyor consists of the belt, which is constructed of multiple plys to provide the required strength and wear resistance; the belt is constructed into a closed loop and stretched between a head and tail pulley; the belt is supported with idlers between the head and tail, and they maintain the appropriate trough shape as well as support the weight of the material in the belt. The head pulley is connected to a motor to power the conveyor. These belts range in width from a few feet to more than 8’, and can transport thousands of tons of ore per hour. Although each belt is of limited length based on mechanical constraints, they can be combined into long runs by constructing transfer points to allow one belt to dump onto another. In this fashion, complex networks can be assembled. Here is an example from a surface mine.

Many years ago, the incline angle of the conveyor was limited by the angle of repose of the ore being conveyed. If this angle was exceeded, the material would begin to slide down the conveyor and would no longer be conveyed upward. Modern designs and significant material improvements now permit belt angles up to 90°, as shown in the second picture.