Course Outline

Introduction and Purpose

Overview

Module Goal

To sensitize you to the central role that phase behavior plays in the petroleum extraction processes.

Module Objective

At the completion of this module, you should be able to describe, in concrete terms, how knowledge of fluid phase behavior impacts specific aspects of the process design and/or operations you are engaged in.

Introduction

The basic essence of engineering is to harness the tremendous energy of the universe, in its latent or potent form, to resolve socio-economic problems. Most often than not in the process, energy must be converted from its natural form into a form that is more amenable to human utilization. Petroleum and natural gas engineering is no different. It is a discipline focused on efficiently extracting the petroleum buried deep within the earth and getting it to where it is needed. The petroleum fluids of particular interest to the petroleum and natural gas engineers are crude oil and natural gas. The term crude oil is used broadly here as to encompass the different forms of petroleum liquids that are used for energy and other purposes.

Natural gas and crude oil are naturally occurring hydrocarbon mixtures; generally they are referred to as petroleum fluids. These fluids are found underground at elevated pressure and temperature conditions. Petroleum fluids are composed principally of hydrocarbons; various non-hydrocarbon components, such as nitrogen, carbon dioxide, and hydrogen sulfide, may also be present.

Producing, separating, transporting, and storing petroleum fluids are the primary responsibilities of a petroleum and natural gas engineer. Therefore, we make no mistake when we refer to natural gas and petroleum engineers as petroleum fluid engineers. These engineers deal with hydrocarbon fluids to make a living. As a consequence, they may very well be referred to as hydrocarbon fluid engineers. One cannot overemphasize the importance of the primary fluids — oil and natural gas — to the modern industrial society. Indeed, modern man’s reliance upon natural gas and crude oil as the primary source of energy is such that these fluids are absolutely critical to the operation of today’s industrial society. It is fair to assume that you, the reader, are interested in hydrocarbon fluids production.

At every stage of the petroleum exploration and production business, a hydrocarbon fluid engineer is needed. Hydrocarbon fluid engineers might find themselves dealing with activities such as reserve evaluations, drilling operations, reservoir analyses, production operations, and gas processing. They are, therefore, called upon to deal with a wide spectrum of activities, mostly dealing with fluid handling and the associated facilities.

Most of the fluid handling protocols require the engineer to know a priori how the fluids will behave under a wide range of pressure and temperature conditions, particularly in terms of their volumetric and thermophysical properties. For example, the engineers should know if the reservoir contains a dry gas, a wet gas, or a gas-condensate before they design the surface production facility. This is collectively termed fluid phase behavior. It is therefore, not an overstatement to say that a thorough understanding of hydrocarbon fluid phase behavior is essential for the work of a petroleum and natural gas engineer. Phase behavior has defining implications in petroleum and natural gas engineering processes. Pressure, volume, and temperature (PVT) relations are required in simulating reservoirs, evaluating reserves, forecasting production, designing production facilities, and designing gathering and transportation systems.

En route from a subsurface reservoir to man’s energy extracting combustion processes, a hydrocarbon molecule goes through various phase- and property-altering intermediate stages. These properties are crucial in designing and operating the processes efficiently and optimally. Phase behavior thermodynamics gives us the tools needed for gaining the desired understanding of how fluids behave at any of those stages.

Questions?

If you have questions at any time during this lesson, please feel free to post them to the Course Introduction Discussion Forum. (Click on the Discussions tab under Home in Canvas to access our course discussion forums.)

Why Study Phase Behavior?

Natural gas and crude oil are naturally occurring hydrocarbon mixtures that are found underground and at elevated conditions of pressure and temperature. They are generally referred to as petroleum fluids. Petroleum fluids are principally made up of hydrocarbons; but few non-hydrocarbon components may be present such as nitrogen, carbon dioxide and hydrogen sulfide.

We make no mistake when we refer to Natural Gas and Petroleum Engineers as Fluid Engineers. This is, engineers that deal with fluids to make a living. Moreover, we specialize in two special fluids whose importance to the society cannot be overstated--indeed, humankind rely on natural gas and crude oil as the premier source of energy that keeps the society operative. As a consequence, we may very well be titled as Hydrocarbon Fluid Engineers. That is everything we are basically about. At every stage of the oil business, a Hydrocarbon Fluid engineer is required. This is, reservoir analyses, drilling operation, production operation, processing, among others, reveal the wide spectrum of areas where an engineer with expertise on hydrocarbon fluids is fundamental.

This said, what can be more important for a Hydrocarbon Fluid Engineer than understanding how these fluids behave?

It is not an overstatement to say that a through understanding of hydrocarbon phase behavior is quintessential for the Petroleum and Natural Gas Engineer. Phase Behavior has many implications in natural gas and petroleum engineering. Pressure, volume, temperature (PVT) relations are required in simulating reservoirs, evaluating reserves, forecasting production, designing production facilities and designing gathering and transportation systems.

Every hydrocarbon molecule in the reservoir is to embark on a fascinating journey from beneath the earth, passing through a great deal of intermediate stages, to be finally dumped into our atmosphere upon combustion (release of energy). Phase Behavior is the part of thermodynamics that gives us the tools for the complete understanding of how fluids behave at any of those stages. Let us be the witnesses of this exciting journey.

Summary

Regardless of the aspect of petroleum extraction process — be it drilling, reserve estimation, reservoir performance analysis, reservoir simulation, tubing flow hydraulics, gathering design, gas-liquid separation, oil and gas transmission, oil and gas metering or quality control — a good predictive knowledge of phase behavior is called for. This course will help you to acquire this knowledge. You may never have to develop computer routines for doing many of the predictive calculations pertaining to hydrocarbon fluid phase behavior; nevertheless, the knowledge base developed in this course will help you develop the understanding needed to be an intelligent user of commercial software packages and ask the right questions that your responsibility as an engineer demands.

Action Item

Write a paragraph or two describing, very briefly, your educational background and practical experience, including your knowledge of phase behavior (if any) and how you apply or have applied this subject matter in your current or recent work assignments. Post your paragraph(s) to the Module 1 Message Board in our online course environment Canvas [1]. From our Canvas course environment, click on the In Touch tab.

- Scroll down to the "Message Boards" section, then click on the link for Module 1 Message Board.

- In the message space provided, type in your paragraph(s) or paste them in if you drafted them first in another application.

- Click on the Save button to post your message.

- Click on the other student postings in the listing of threaded messages to learn more about your fellow classmates.

Phase Diagrams, Part I

Module Goals

Module Goal: To familiarize you with the basic concepts of phase diagrams as a means of representing thermodynamic data.

Module Objective: To highlight the basic description of phase diagrams of single-component systems.

Introduction

One of the primary challenges that we face as engineers is how to communicate large quantities of complex information to our peers and superiors. For instance, we may need to report what thermodynamic changes our working fluid is undergoing. Here, the familiar saying: A picture is worth a thousand words applies. Although most non-engineers believe that the only language an engineer speaks is mathematics, in actuality, the most effective means that engineers use to communicate information involves the use of pictures or diagrams. Phase behavior is not an exception. In phase behavior thermodynamics, phase diagrams are used precisely for this purpose.

Phase Diagram:

A phase diagram is a concise graphical method of representing phase behavior of fluids. It provides an effective tool for communicating a large amount of information about how fluids behave at different conditions.

First of all, let us classify fluids into two broad groups on the basis of the number of components that are present in the system: pure component systems and mixtures.

Two Classes of Fluids

-

Pure-component systems

-

Mixtures

Although this classification may seem trivial at a first glance, it recognizes the paramount influence of composition on the phase behavior of a fluid system. Whereas for a single-component system, composition is not a variable and therefore cannot influence behavior, the behavior of a mixture is strongly controlled by composition. In fact, as the number of components in the system increases, the complexity of the phase diagram increases as well. Therefore, the simplest form of a phase diagram is that of a system made of only one component (a pure-component system).

Pure-component Systems

Let us start with a well-known single component system: water — the most plentiful substance on earth. What is the behavior of water under different conditions of pressure and temperature? Or even more specific, is there a single answer to the question: what is the boiling point of water? Most people would say, “of course, 100 °C”, but a more accurate response would pose a clarifying question: “At what pressure?” It is common knowledge that water boils at 100 °C (212 °F) at atmospheric pressure. By requiring a pressure specification in order to uniquely define the boiling point of water, we are acknowledging that the boiling temperature of a pure substance is pressure-dependent. In reality, we are also implicitly applying a very useful thermodynamic principle, the Gibbs Rule, but this will be the topic for later discussion.

In thermodynamics, we refer to the Normal Boiling Point as the boiling temperature of a fluid at 1 atm of pressure (that is, atmospheric pressure.) Therefore, 100 °C (212 °F) is the normal boiling point of water.

What if we want to communicate this idea? We would like to communicate the concept that the temperature at which water boils varies with pressure. What about a picture to represent this information? Here is our first phase diagram, Figure 2.1. Whereas several sentences may be required to describe the variability of the boiling point of water, the single line shown in Figure 2.1 is adequate. What does Figure 2.1 tell us? It tells us that the boiling temperature of a liquid increases as pressure increases. In other words, it says that the vapor pressure of a liquid increases as temperature increases. That is to be expected because as the temperature increases, more liquid molecules are able to escape into the vapor phase, thus increasing the pressure that the aggregate of all vapor molecules exerts on the system (i.e. vapor pressure).

The curve in Figure 2.1 is called the vapor pressure curve or boiling point curve. The line also represents the dew point curve and the bubble point curve; one on top of the other. This curve represents the transition between the vapor and liquid states.

Definition of Basic Terms

Vapor Pressure: The pressure that the vapor phase of a fluid exerts over its own liquid at equilibrium at a given temperature.

Dew Point: The pressure and temperature condition at which an infinitesimal quantity of liquid (a droplet) exists in equilibrium with vapor. It represents the condition of incipient liquid formation in an initially gaseous system. Notice that it can be also visualized as a “liquid system” where all but an infinitesimal quantity of liquid has been vaporized.

Bubble Point: The pressure and temperature condition at which the system is all liquid, and in equilibrium with an infinitesimal quantity (a bubble) of gas. This situation is, in essence, the opposite of that of the dew point.

Note:

For single-component systems, one single curve represents all three of these conditions (vapor pressure, dew point and bubble point conditions) simply because Vapor Pressure = Dew Point = Bubble Point for unary systems.

In Figure 2.1, once a saturation pressure has been selected, there is one (and only one) saturation temperature associated with it. This is only true for a single component system. In other words, this is the only temperature (at the given pressure), at which liquid and gas phase will co-exist in equilibrium. The rule that governs the uniqueness of this point, for a single-component system, is called the Gibbs Phase Rule. This is the second time we have mentioned this rule, pointing to its great importance in phase behavior. Let us postpone any detailed discussion of the Gibbs Phase Rule until later.

The vapor curve, shown in Figure 2.1, represents the transition between the vapor and liquid states for a pure component. Obviously, this is not the whole story. If we cool the liquid system, it makes sense to expect ice to form (a solid phase). We can communicate this new idea by adding more information to Figure 2.1. In fact, there is a line that defines the liquid-solid transition; it is called the solidification (or melting) curve (see Figure 2.2). Furthermore, even though it is counter-intuitive, it is possible to go from solid to vapor without going through a liquid state, if the pressure is low enough. This information can be added to the diagram by including the sublimation curve. Thus, Figure 2.2 represents a more complete phase diagram for a pure-component system.

See how more and more information can be represented within the limits of the phase diagram. As petroleum and natural gas engineers, we focus our attention on the Boiling Point Curve, as it represents the transition between liquid and gas, the phases with which we deal most often. Let us focus our attention on it.

Figure 2.3 presents a P-T diagram representing the vapor pressure curve and its extremities. Two very important thermodynamic points bound the vapor pressure curve: the Critical Point at its upper end and the Triple Point at its lower end.

The Triple Point is the meeting point of the vapor pressure, solidification and sublimation curves (see Figure 2.2); hence, it represents the only condition at which all three phases of a pure substance (solid, liquid and gas) can co-exist in equilibrium.

At the Critical Point, gas and liquid are in equilibrium without any interface to differentiate them; they are no longer distinguishable in terms of their properties. As we recall, the only location on the P-T diagram where liquid and gas can be found together in equilibrium is along the vapor pressure curve. Hence, the critical point is clearly the maximum value of temperature and pressure at which liquid and vapor can be at equilibrium. This maximum temperature is called the critical temperature (Tc); the corresponding maximum pressure is called the critical pressure (Pc).

Let us conclude this first module by highlighting the most important properties of the critical point of pure substances, as shown below. The next module will be providing more details of interest that are embedded in Figure 2.3.

Properties Of The Critical Point (Tc,Pc) (For Pure Substances):

- Temperature and pressure for which liquid and vapor are no longer distinguishable.

- For T > Tc, liquid and vapor will not co-exist, no matter what the pressure is.

- For P > Pc, liquid and vapor will not co-exist, no matter what the temperature is.

Action Item

Answer the following problems, and submit your answers to the drop box in Canvas that has been created for this module.

Please note:

- Your answers must be submitted in the form of a Microsoft Word document.

- Include your Penn State Access Account user ID in the name of your file (for example, "module2_abc123.doc").

- The due date for this assignment will be sent to the class by e-mail in Canvas.

- Your grade for the assignment will appear in the drop box approximately one week after the due date.

- You can access the drop box for this module in Canvas by clicking on the Lessons tab, and then locating the drop box on the list that appears.

Problem Set

-

Speculate on what the difference would be between phase diagrams (P-T curve) of various pure component systems. Write a paragraph or so on what you believe the differences are and why.

-

What should be the differences in the diagrams in question 1? Are the dew points the same? What about the bubble points? And their critical points?

Phase Diagrams, Part II

Module Goals

Module Goal: To familiarize you with the basic concepts of phase diagrams as a means of representing thermodynamic data.

Module Objective: To familiarize you with the use of P-T and P-v diagrams.

Vapor Pressure Curve

From the last module you will recall that the vapor-pressure curve (Figure 2.3) and its extremities were examined. That figure is presented in this module in Figure 3.1. We concluded that two very important thermodynamic points bound the vapor pressure curve: the Critical Point at its upper end and the Triple Point at its lower end.

Now let us take a second look at this figure. We can better understand the information represented by the vapor pressure curve by looking at the process of isobaric heating. This is illustrated by line ACB in Figure 3.2. The term “isobaric” pertains to a constant pressure process. By isobaric heating process, we then mean a “constant pressure addition of heat into a system.”

Such a process can be described as follows. Starting at point A and moving towards point C at constant pressure, we add heat to the system. By adding this heat, we cause a temperature increase in the system (Temperature at C > Temperature at A.). At point C, which lies above the vapor pressure or boiling point curve, we encounter a phase change. To the left of point C, at lower temperatures, exists only liquid. To the right of point C, at higher temperatures, there is only vapor. Therefore, a sharp discontinuity in density exists at point C. During this transition, from liquid to vapor, we will notice that the heat that we add to the system does not cause any temperature increase, and in fact, temperature and pressure conditions remain constant during the transition represented by the vapor curve. In other words, even though we are adding heat, the system remains at the pressure and temperature associated with point C until the whole phase transition has taken place — i.e., until all the vapor is converted to liquid. Instead of working to increase liquid temperature, this heat serves to move liquid molecules apart until all liquid has become vapor.

Up to this point, we saw that the heat added before the system reached the phase transition was used to raise the temperature of the substance. However, the heat that we are adding right now, during the phase transition, is not causing any temperature increase (hence it is said to be hidden heat or latent heat of vaporization). Therefore, we differentiate between two kinds of heat: sensible heat and latent heat.

Sensible Heat: Its main purpose is to cause an increase in temperature of the system.

Latent Heat: It serves only one purpose: to convert the liquid into vapor. It does not cause a temperature increase.

In fact, the name “latent” suggests “hidden.” Here, we are adding heat to the system but are not seeing its effect in terms of temperature increase. The heat that is needed to transform one mole of saturated liquid into vapor is known as the latent molar heat of vaporization:

Once we have converted all the liquid into vapor (i.e., we supplied all the necessary latent heat to accomplish this), we may continue to add more heat. If we do so, the temperature will rise again and we will end at point B (Figure 3.2). This heat is also sensible since it is causing the temperature of the system to rise.

It is interesting to note that, in order to reverse the process from point B to point A, we will have to remove the exact amount of heat that we had added before. This is a basic consequence of an energy balance principle. We call such a reverse process an isobaric cooling process. We will have to remove some sensible heat in order to cool the vapor from point B to C, and then we will remove all the latent heat of the vapor to condense it into liquid (transition at point C). Finally, we will also need to remove more sensible heat from the system for the cooling of the liquid from point C to point A.

In the previous two processes, from A to B or vice versa, we had to cross the phase boundary represented by the vapor pressure curve. However, this is not the only thermodynamic path that is available for us to go from A to B. Figure 3.3 depicts another possible path.

Instead of doing the whole process isobarically, we may devise a new path that may also accomplish the goal of taking the system from a condition ‘A’ to a condition ‘B.’ Consider the path ADEB that is shown in Figure 3.3.

Sequence of Paths

- Path AD: Isothermal compression

- Path DE: Isobaric heating

- Path EB: Isothermal expansion

There is something remarkable about this new path. Unlike the previous path, notice that we do not cross the phase boundary at all. The consequences of taking this new road may seem astonishing at first glance: we went from an all-liquid condition (point A) to an all-vapor condition (point B) without any sharp phase transition. In fact, along the path ADEB there is NO phase transition because we never crossed the phase boundary. Since the phase boundary represents a sharp discontinuity in density (and other physical properties), the fact that we are not crossing it tells us that as we go, there is actually a gradation in density (from a liquid like, or high-density at point A to a gas like, or low-density at point B) instead of a sharp change from the high liquid density to the low gas density.

We were able to do so because we went above the critical conditions. In the vicinity of and beyond critical conditions, we are no longer able to distinctly label the single-phase condition as either “liquid” or “gas”. Under these conditions, any transition takes place gradually without any differentiation between a ‘liquid’ and a ‘gas’ phase. We call this fluid, which we cannot define either as a liquid or as a gas, a supercritical fluid. In terms of density, a supercritical fluid may be described, at the same time, as a light liquid (its density is not as high as the liquid density) and a heavy gas (its density is not as low as the typical gas density of the given substance). The behavior of fluid around this area is an active and interesting area of current research.

In summary, for a pure substance, you can avoid having an abrupt phase transition (such as the one described by the path ACB) by going around the critical point (path ADEB). Keep in mind that any path that crosses the vapor pressure curve (ACB) will undergo a phase transition.

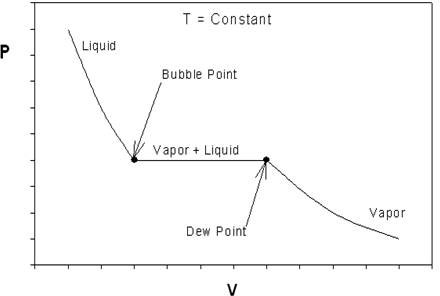

PV Diagram for Pure Systems

In the previous discussion, we used the P-T diagram and were not concerned about changes in the volume of the system. If we want to follow changes in volume, we may construct P-v or T-v diagrams, in which we hold temperature (T) or pressure (P) constant. Let us consider the case of a P-v Diagram (Figure 3.4).

In this case temperature is being held constant; our substance is undergoing an isothermal compression process. Starting at E (all-vapor condition), an increase in pressure will result in a rather significant reduction in volume since the gas phase is compressible. If we keep compressing isothermally, we will end up at point F, where the gas will be saturated and the first droplet of liquid will appear. We have come to the two-phase condition, where liquid (L) and vapor (V) co-exist in equilibrium, for the first time, albeit an infinitesimal amount of liquid.

Once we reach the two-phase condition, what happens is not intuitive. While we keep on compressing by decreasing the volume (path F-G,) the pressure of the system remains constant; this condition continues until all the vapor has become liquid. Point G represents the last condition of liquid and vapor (L+V) coexistence, saturated liquid condition (liquid in equilibrium with an infinitesimal amount of vapor.) Once we have only liquid, if we keep on compressing (i.e., attempting to reduce liquid volume) we will observe a rapid increase in pressure, as indicated by the steep slope in the P-v diagram. This is because liquid is virtually incompressible, hence, a great deal of pressure is needed to cause a small reduction in volume.

It is important to recognize some points of this process. If we recall our previous definitions of basic concepts, we will recognize point F, where only a tiny quantity of liquid exists in an otherwise completely gaseous system (the dew point of the system at the given temperature). Similarly, Point G is the bubble point; only an infinitesimally small bubble of vapor exists in an otherwise liquid system.

But wait a second. Let us try to compare Figure 3.4 with Figure 3.2. Can we relate them to each other? Where is path F-G in Figure 3.4 represented in Figure 3.2 (repeated below)?

The answer is, path F-G is represented by one point in Figure 3.2; that is, point C. Recall, for a single-component system, dew points and bubble points are identical. During a phase transition, both pressure and temperature must remain constant for pure components.

Now, if we want to generate all the possible points that make up the vapor pressure curve in Figure 3.2, we would need to repeat the experiment for different temperatures. We would end up with a family of isotherms (each similar to the one presented in Figure 3.4). This is represented in Figure 3.5.

The zone where the isotherms become flat delineates the two-phase region. It is clearly seen that by plotting all the pairs in that zone (P1,T1), (P2,T2)… (Pc, Tc) we will be able to reproduce Figure 3.2.

If we now draw a line through all the Bubble Points in Figure 3.5, and then draw a line connecting all the Dew Points, we will end up with the Bubble Point Curve and the Dew Point Curve, respectively. It is clear that the two curves meet at the critical point (Pc, Tc). Furthermore, the two curves delineate the phase envelope, which contains the 2-phase region inside. If we “clean” Figure 3.5 a little, we end up with the phase envelope that is shown in Fig. 3.6.

If you carefully follow the trend of the critical isotherm (@ T = Tc in Fig. 3.5), you will realize that it has a point of inflexion (change of curvature) at the critical point. Furthermore, the critical point also represents the maximum point (apex) of the P-v envelope. Mathematically, this information is conveyed by the expressions:

$$\left(\frac{\partial P}{\partial \vec{V}}\right)_{P C, T C}=\left(\frac{\partial^{2} P}{\partial \vec{V}^{2}}\right)_{P C T C}=0$$

which are usually known as the criticality conditions. These conditions are always satisfied at the critical point. We will comment more on this after we begin the discussion on Equations of State (EOS) — semi-empirical relationships that mathematically model the P-v-T behavior of fluids.

Action Item

Answer the following problems, and submit your answers to the drop box in Canvas that has been created for this module.

Please note:

- Your answers must be submitted in the form of a Microsoft Word document.

- Include your Penn State Access Account user ID in the name of your file (for example, "module2_abc123.doc").

- The due date for this assignment will be sent to the class by e-mail in Canvas.

- Your grade for the assignment will appear in the drop box approximately one week after the due date.

- You can access the drop box for this module in Canvas by clicking on the Lessons tab, and then locating the drop box on the list that appears.

Problem Set

- Explain in your own words (no more than a paragraph) why the 2-Phase segment of the P-v isotherm should correspond to one single point in the P-T diagram.

- What about the critical point in the P-T diagram? Which P-v isotherm could that correspond to?

- Take two different hydrocarbons (say, C1 and C2) and compare their P-T vapor pressure curves. What do you notice? As you saw in the previous module, those P-T curves will be found at different conditions of pressure and temperature. But more than that, what can you comment about the slopes of both curves? Are they different? Why? Speculate.

Phase Diagrams, Part III

Module Goals

Module Goal: To familiarize you with the basic concepts of Phase Diagrams as a means of representing thermodynamic data.

Module Objective: To introduce you to the additional complexity brought about by the presence of one or more additional components.

Binary Systems

Thus far, we have focused our attention on single-component systems (also called unary, one-component, or pure-component systems). However, real-life systems are never single-component; they are multicomponent systems. The simplest of this category is the binary system. The good news, however, is that the behavior of multicomponent systems are quite similar to that of binary systems. Therefore, we will focus on binary systems, since they are easier to illustrate.

Let us place two gases (A and B) in an isothermal cell. As we did before, we will keep temperature constant during this experiment (shown in Fig. 4.1)

If we move the piston down, we would compress the gasses, causing a decrease in volume. In such a scenario, an increase in pressure would occur. The process starts at point A, as shown in Figure 4.2, an all-vapor condition.

Nothing here is new regarding the compression of the vapor itself. As pressure increases, volume decreases accordingly. After some compression, the first droplet of liquid will appear. That is, we have found the dew point of the mixture (point B). We then proceed with compression. As we further compress the system, more liquid will appear and the volume will continue to decrease.

It would appear that we are seeing here the same features as those of the single-component system that we studied in the previous modules. But wait a minute, is that so?

Actually, there is a difference. During the phase transition, pressure does not remain constant in this experiment. In fact, as compression progresses and more liquid is formed, pressure keeps rising — although not as sharply as in the single-phase vapor region. When the entire system has become liquid, with only an infinitesimal bubble of vapor left, we are at point C — the bubble point of the mixture. Please note that, for binary mixtures (as is the case for multicomponent mixtures,) the dew point and bubble point do not occur at the same pressure for isothermal compression. If you recall, for the single-component system, the dew point and the bubble point coincide. This is not true for binary and multicomponent systems. Compare Figure 4.2 with Figure 3.4 (repeated below from Module 3) to see this point.

WHY?? Why is pressure increasing during the phase transition? At this point, we start to realize the ways in which composition plays a fundamental role in the behavior of mixtures.

In a single-component system, both liquid and vapor in the two-phase region have the same composition (there is only one chemical substance within the system). Now, when a mixture exists in a two-phase condition, different molecules of different species are present and they can be either in a liquid or vapor state (two-phase condition). Some of them would “prefer” to be in the gas phase while the others would “prefer” to be in the liquid phase. This “preference” is controlled by the volatility of the given component. When we reach point B (Figure 4.2) and the first droplet of liquid appears, the heaviest molecules are the ones that preferentially go to that first tiny droplet of liquid phase. For ‘heavy’ molecules, given the choice, it is more desirable to be in the condensed state.

As we keep on forming more liquid (by compression), mainly light molecules remain in the vapor phase. However, at the end point of the transition (point C in Figure 4.2) we have forced all of them to go to the liquid state — they no longer have a choice. This enforcement requires greater pressure. If you compare a sample of liquid at dew point conditions (point B in Figure 4.2) to one taken in the middle of the transition, it is clear that the former would be richer in heavy components than the latter. The properties of the heaviest component would be most influential at the dew point (when the liquid first appears); while the properties of the lighter component would be most influential at the bubble point (when the last bubble is about to disappear.)

In the two-phase region, pressure increases as the system passes from the dew point to the bubble point. The composition of liquid and vapor is changing; but — watch out! — the overall composition is always the same! At the dew point, the composition of the vapor is equal to the overall composition of the system; however, the infinitesimal amount of liquid that is condensed is richer in the less volatile component. At the bubble point, the composition of the liquid is equal to that of the system, but the infinitesimal amount of vapor remaining at the bubble point is richer in the more volatile component than the system as a whole.

In general, when two different species are mixed, some of the behaviors of the individual species and their properties will change. Their usual behavior (as pure components) will be altered as a consequence of the new field of molecular interactions that has been created. While kept in a pure condition, molecules only interact with like molecules. On the other hand, in a mixture new interactions between dissimilar molecules occur.

Our next step, in order to continue this discussion in a coherent manner, is to draw the complete P-V diagram for this binary mixture by delineating the two-phase region. In the same way as we did previously, we delineate the two-phase region by drawing a complete family of isotherms in the P-V diagram. Figure 4.3 illustrates this.

Again, the line connecting all of the bubble and dew points will generate the bubble and dew point curve, both of which meet at the critical point. Notice that the critical point does not represent a maximum in the P-V diagram of a mixture. Also note that bubble point pressures and dew point pressures are no longer the same.

Again, the isotherms through the two-phase region are not horizontal but have a definite slope. This must have an implication. In fact, it does. What if we now want to plot the P-T diagram for this mixture? Will we have only a single line, where bubble and dew point curves lie on top of each other, as we had for a single-component system? Of course not. Instead of both curves being together, the bubble point curve will shift to the upper left (higher pressures) and dew point curve will shift to the lower right (lower pressures) — both of them meeting at the critical point. Figure 4.4 shows us a typical phase envelope for a mixture.

Notice the enormous difference between the P-T curve of a multi-component system (binary system in this case, Fig. 4.4) and the P-T curve of a pure (single) component (Fig. 3.1 of Module 3, repeated below). The only system for which the bubble point curve will coincide with the dew point curve is a single component system, where we have a single line for the P-T diagram (for example, the boiling point curve represented in Fig. 3.1). In Fig 3.1, the critical point represents the maximum set of (P,T) values that you could find in the P-T graph.

This is not all. There are some other implications. Can we say now that the critical point is the maximum value of pressure and temperature where liquid and gas can coexist? Look at Figure 4.4 again. Obviously not. The critical point is no longer at the apex or peak of the two-phase region; hence, vapor and liquid can coexist in equilibrium at T > Tc and P > Pc. In fact, we can identify two new maxima: condition Pcc is the maximum pressure and condition Tcc is the maximum temperature at which L+V will be found in equilibrium. We assign special names to these points. There are the cricondenbar and cricondentherm, respectively.

Clearly, the only definition that now can still hold for the critical point — both for mixtures and pure components — is the one shown below.

Critical Point (Pc,Tc): The temperature and pressure for which liquid and vapor are indistinguishable.

Again, this definition is applicable both for mixtures and pure-component systems; it does not make any reference to maximum values in the curve. These maximum values, as we said, have special names in the case of mixtures. Thus, for mixtures, we have to additionally define:

Cricondentherm (Tcc):

- The highest temperature in the two-phase envelope.

- For T > Tcc, liquid and vapor cannot co-exist at equilibrium, no matter what the pressure is.

Cricondenbar (Pcc):

- The highest pressure in the two-phase envelope.

- For P > Pcc, liquid and vapor cannot co-exist at equilibrium, no matter what the temperature is.

In the case of the unary system, besides dew and bubble point curves lying on top of each other, it is clear that cricondentherm, cricondenbar, and critical conditions are also represented by a single point (that is, the critical point itself.) This is clear from all three previous definitions. Thus, as we saw before, the definition for critical point in unary systems encompasses all three of the definitions given above.

For pure substances only:

Cricondentherm = Cricondenbar = Critical Point.

Retrograde Phenomenon

Regarding multi-component mixtures (where the binary system is the simplest case), some interesting phenomenon profoundly differentiate their behavior from the behavior of single-component systems. We are now talking about retrograde phenomena.

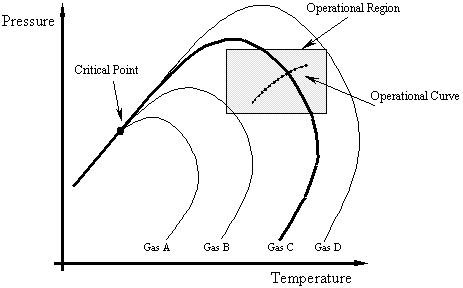

In the previous section, we learned how the “critical point” for a single-component system meant everything: the highest pressure and temperature at which two phases can exist and the point for which liquid and vapor phases are indistinguishable. Then we learned that this is not the case for multicomponent systems. Although the critical point for these systems is the common point between the dew and bubble point curves (the point for which liquid and vapor phases are indistinguishable), in general, this point neither represents the maximum pressure nor the maximum temperature for vapor-liquid coexistence. In fact, we gave new names to these maxima: cricondenbar (for the maximum pressure) and cricondentherm (for the maximum temperature). Let’s look at this again in Figure 4.5, where the critical point (Pc, Tc), cricondentherm (Tcc), and cricondenbar (Pcc) are highlighted.

Please recall that the bubble point curve represents the line of saturated liquid (100 % liquid with an infinitesimal amount of vapor) and the dew point curve represents the line of saturated vapor (100 % vapor with an infinitesimal amount of liquid). These conditions are all shown in Figure 4.5.

Let us now consider the isothermal processes taking place at T = T1 and T = T2, represented in Figure 4.6.

Figure 4.6 shows us two cases of isothermal compression for two different temperatures T1 and T2. Notice that these temperatures are such that T1 < Tc and Tc < T2 < Tcc.

It is common knowledge that an isothermal compression (increasing pressure while temperature is held constant) causes the condensation of a vapor (steam, in the case of water). That is the normal or expected behavior of a vapor under compression: the more you compress it, the more liquid you get out of it after the saturation conditions have been reached. This is always true for a pure-component system, such as water.

Well, that is exactly what is happening for our first case, the isothermal compression at T = T1. At point A, we are in an ALL VAPOR condition (0 % liquid) and we are starting to cross over into the two-phase region. As we compress from point A to B, more and more liquid is formed until the entire system has been condensed (point B). We went all the way from 0 % liquid to 100 % liquid, as we expected, by compressing the vapor. How liquid yield progresses with pressure is shown in Figure 4.7.

Again, there is nothing contrary to expectations here, and we would get the same result as long as T < Tc. However, there is something very interesting going on within the region Tc < T < Tcc.

In the second case (Tc < T2 < Tcc), we have a different behavior. At point C (Figure 4.6), we are starting in an ALL VAPOR condition (0 % liquid); by increasing pressure, we force the system to enter the two-phase region. Thus, some liquid has to drop out; we expect that as the pressure keeps increasing, we will produce more and more liquid. That is true to some extent… BUT, look at the final point of our journey, point D: although we are producing liquid, our final condition (dew point) requires us to have 0 % liquid in the system again.

How so?? This is telling us that, as we are entering the two-phase region, we will start to produce some liquid; but, there will be a point (of maximum liquid yield) where that liquid will start to vaporize (point C’). In other words, even though we are compressing the system, liquid will vaporize and not condense. Isn’t this contrary to expectations? Yes, and that is why we call this a retrograde (contrary to expectation) behavior.

Figure 4.8 shows a typical curve for the variation of the liquid volume percentage with pressure. This curve can be also referred to as the liquid dropout curve.

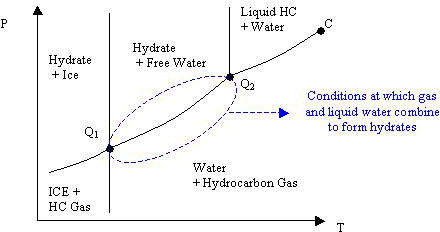

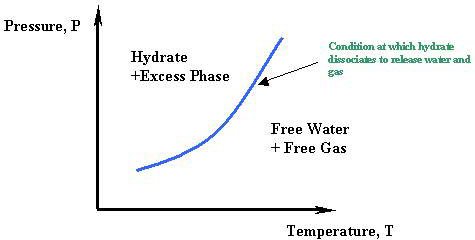

The increase in the liquid fraction with decreasing pressure between points C and D is exactly the opposite of the normal trend. This behavior, however, is typical of gas condensate systems. Retrograde conditions may be encountered in deep-well gas production, as well as in reservoir conditions.

For production operations, usually the objective is to maintain pressure so as to achieve maximum liquid dropout. The initial PVT conditions of the well may correspond to a point above point D. If the conditions at the wellhead are then maintained near point C’, liquid recovery is maximized at the surface. However, maximum liquid dropout is not always sought. At reservoir conditions, the presence of liquid is not desirable in a gas reservoir, because liquids have negligible mobility (at low saturations) and thus, the hydrocarbon would be — for practical purposes — lost forever. Liquid also impairs gas mobility; hence, liquid production at reservoir conditions is to be avoided at all times in a gas reservoir. This is often achieved by repressurization or lean gas injection.

It is also important to see that a similar behavior is to be expected within the region Pc < P < Pcc. In this case, we talk about retrograde vaporization since we will be moving from a 100 % liquid to another 100 % liquid condition (both on the bubble point curve) in an isobaric heating.

Action Item

Answer the following problems, and submit your answers to the drop box in Canvas that has been created for this module.

Please note:

- Your answers must be submitted in the form of a Microsoft Word document.

- Include your Penn State Access Account user ID in the name of your file (for example, "module2_abc123.doc").

- The due date for this assignment will be sent to the class by e-mail in Canvas.

- Your grade for the assignment will appear in the drop box approximately one week after the due date.

- You can access the drop box for this module in Canvas by clicking on the Lessons tab, and then locating the drop box on the list that appears.

Problem Set

-

Compare and contrast the definition of critical point for a single component system and a mixture. What is common between these two systems and what is not? Explain.

-

Do the cricondentherm and cricondenbar play a similar role as the critical point? If not, why? What is the difference?

- In a couple of sentences, speculate on the physics of why we have retrograde phenomena.

- Compare and contrast the 2-Phase segment of the P-v isotherm for single components and the P-v isotherm for a binary system. What is the difference?

Phase Diagrams, Part IV

Module Goals

Module Goal: To familiarize you with the basic concepts of Phase Diagrams as a means of representing thermodynamic data.

Module Objective: To familiarize you with the process of extracting quantitative compositional information from phase envelopes.

Effect of Composition on Phase Behavior

Let us try to reconcile the P-T graphs for the binary mixture with what we know from P-T graphs for single-component systems. At the end of the day, a mixture is formed by individual components which, when pure, act as presented in the P-T diagram shown in Fig. 3.1 [Module 3, repeated below]. We would, therefore, expect that the P-T diagram of each pure component will have some sort of influence on the P-T diagram of any mixture in which it is found.

In fact, it would be reasonable to think that as the presence of a given component A dominates over B, the P-T graph of that mixture (A+B) should get closer and closer to that of A as a pure component.

What this is telling us is that a new variable is coming into the picture: composition. So far we have not considered the ratio of component A to component B in the system. Now we are going to study how different ratios (compositions) will give different envelopes, i.e., different P-T behaviors.

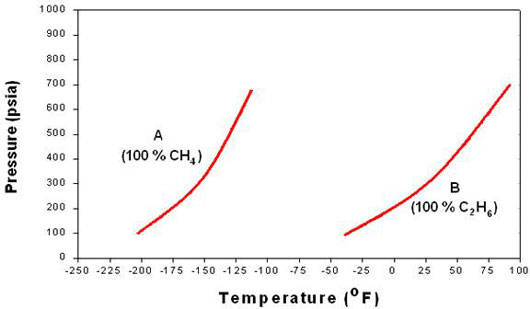

Let us say that we have a mixture of components A (Methane, CH4) and B (Ethane, C2H6), where A is the more volatile of the two. It is clear that for the two pure components, we would have two boiling point curves for each component (A and B) as shown in Figure 5.1.

Please notice that the position of each of curve with respect to the other depends on its volatility. Since we are considering A to be the more volatile, it is expected to have higher vapor pressures at lower temperatures, thus, its curve is located towards the left. For B, the less volatile component, we have a boiling point curve with lower vapor pressures at higher temperatures. Hence, the boiling point curve of B is found towards the right at lower pressures.

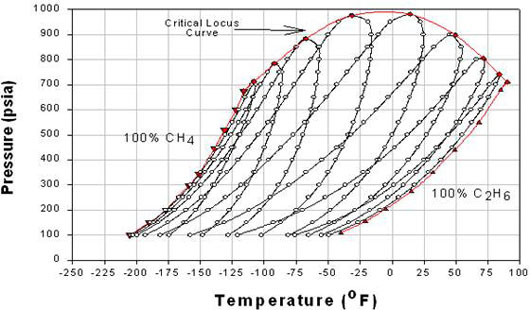

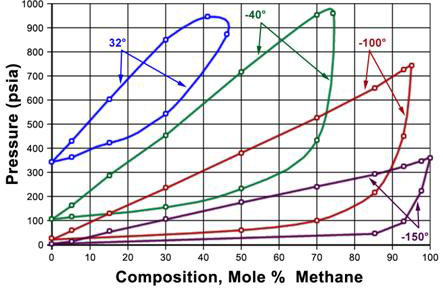

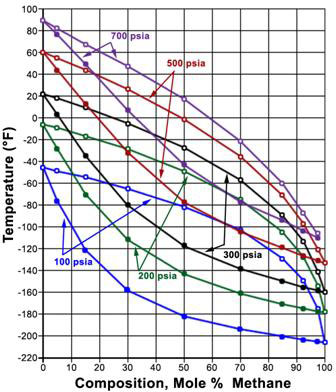

Now, if we mix A and B, the new phase envelope can be anywhere within curves A and B. This is shown in Figure 5.2, where the effect of composition on phase behavior of the binary mixture Methane/Ethane is illustrated.

In Figure 5.2, each phase envelope represents a different composition or a particular composition between A and B (pure conditions). The phase envelopes are bounded by the pure-component vapor pressure curve for component A (Methane) on the left, that for component B (Ethane) on the right, and the critical locus (i.e., the curve connecting the critical points for the individual phase envelopes) on the top. Note that when one of the components is dominant, the curves are characteristic of relatively narrow-boiling systems, whereas the curves for which the components are present in comparable amounts constitute relatively wide-boiling systems.

Notice that the range of temperature of the critical point locus is bounded by the critical temperature of the pure components for binary mixtures. Therefore, no binary mixture has a critical temperature either below the lightest component’s critical temperature or above the heaviest component’s critical temperature. However, this is true only for critical temperatures; but not for critical pressures. A mixture’s critical pressure can be found to be higher than the critical pressures of both pure components — hence, we see a concave shape for the critical locus. In general, the more dissimilar the two substances, the farther the upward reach of the critical locus. When the substances making up the mixture are similar in molecular complexity, the shape of the critical locus flattens down.

Px and Tx Diagrams

In addition to considering variations with pressure, temperature, and volume, as we have done so far, it is also very constructive to consider variations with composition. Most literature on the subject calls these diagrams the “P-x” and “T-x” diagrams respectively. However, a word of caution is needed in order not to confuse the reader. Even though “x” stands for “composition” — in a general sense — here, we will see in the next section that it is also customary to use “x” to single out the composition of the liquid phase. In fact, when we are dealing with a mixture of liquid and vapor, it is customary to refer to the composition of the liquid phase as “xi” and use “yi” for the composition of the vapor phase. “xi” pertains to the amount of component in the liquid phase per mole of liquid phase, and “yi” pertains to the amount of component in the vapor phase per mole of vapor phase. However, when we talk about composition in general, we are really talking about the overall composition of the mixture, the one that identifies the amount of component per unit mole of mixture. It is more convenient to call this overall composition “zi”. If we do so, these series of diagram should be called “P-z” and “T-z” diagrams. This is a little awkward in terms of traditional usage; and hence, we call them “P-x” and “T-x” where “x” here refers to overall composition as opposed to liquid composition.

A P-x diagram for a binary system at constant temperature and a T-x diagram for a binary system at a constant pressure are displayed in Figures 5.3 and 5.4, respectively. The lines shown on the figures represent the bubble and dew point curves. Note that the end points represent the pure-component boiling points for substances A and B.

(Courtesy of ©LOMIC, INC)

In a P-x diagram (Figure 5.3), the bubble point and dew point curves bound the two-phase region at its top and its bottom, respectively. The single-phase liquid region is found at high pressures; the single-phase vapor region is found at low pressures. In the T-x diagram (Figure 5.4), this happens in the reverse order; vapor is found at high temperatures and liquid at low temperatures. Consequently, the bubble point and dew point curve are found at the bottom and the top of the two-phase region, respectively.

The Lever Rule

P-x and T-x diagrams are quite useful, in that information about the compositions and relative amounts of the two phases can be easily extracted. In fact, besides giving a qualitative picture of the phase behavior of fluid mixtures, phase diagrams can also give quantitative information pertaining to the amounts of each phase present, as well as the composition of each phase.

For the case of a binary mixture, this kind of information can be extracted from P-x or T-x diagrams. However, the difficulty of extracting such information increases with the number of components in the system.

At a given temperature or pressure in a T-x or P-x diagram (respectively), a horizontal line may be drawn through the two-phase region that will connect the composition of the liquid (xA) and vapor (yA) in equilibrium at such condition — that is, the bubble and dew points at the given temperature or pressure, respectively. If, at the given pressure and temperature, the overall composition of the system (zA) is found within these values (xA < zA < yA in the T-x diagram or yA < zA < xA in the P-x diagram), the system will be in a two-phase condition and the vapor fraction (αG) and liquid fraction (αL) can be determined by the lever rule:

(5.1a)

(5.1b)

Note that αL and αG are not independent of each other, since αL + αG = 1. Figure 5.5 illustrates how equations (5.1) can be realized graphically. This figure also helps us understand why these equations are called “the lever rule.” Sometimes it is also known as the “reverse arm rule,” because for the calculation of αL (liquid) you use the “arm” within the (yA-xA) segment closest to the vapor, and for the vapor calculation (αG) you use the “arm” closest to the liquid.

At this point you will see clearly why we needed to make a clear distinction among “xi” and “yi” and “zi”. Expressions (5.1) can be derived from a simple material balance. Can you prove it? [Hint: The number of moles of a component “i” per mole of mixture in the liquid phase is given by the product “xiαL”, while the number of moles of “i” per mole of mixture in the gas is given by “yiαG”. Since there are “zi” moles of component “i” per mole of mixture, the following must hold: . Can you proceed from here?]

Ternary Systems

The next more complex type of multi-component system is a ternary, or three-component, system. Ternary systems are more frequently encountered in practice than binary systems. For example, air is often approximated as being composed of nitrogen, oxygen, and argon, while dry natural gas can be rather crudely approximated as being composed of methane, nitrogen and carbon dioxide. We can also have pseudo 3-component systems, which consist of multicomponent systems (more than 3 components) that can be described by lumping all components into 3 groups, or pseudo-components. In this case, each group is treated as a single component. For example, in CO2 injection into an oil reservoir, CO2, C1, and C2 are often lumped into a single light pseudo-component, while C3 to C6 form the intermediate pseudo-component, and the others (C8+) are lumped together into a single heavy pseudo-component.

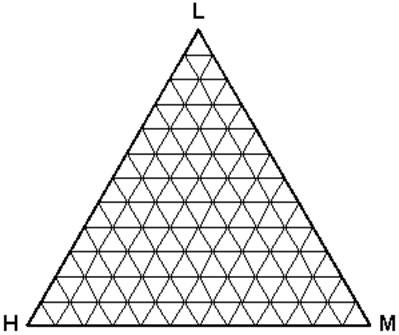

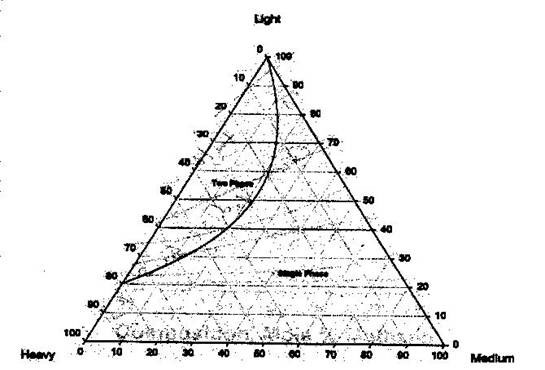

Intuitively, having more than two components poses a problem when a pictorial representation is desired. A rectangular coordinate plot, having only two axes, will no longer suffice. Gibbs first proposed the use of a triangular coordinate system. In modern times, we use an equilateral triangle for such a representation. Figure 5.6 shows an example of a ternary phase diagram. Note that the relationship among the concentrations of the components is more complex than that of binary systems.

Features:

- Any point within this triangle represents the overall composition of a ternary system at a fixed temperature and pressure.

- By convention, the lightest component (L) is located at the apex or top of the triangle. The heavy (H) and medium (M) components are placed at the left hand corner and right hand corner, respectively.

- Every corner represents a pure condition. Hence, at the top we have 100 % L, and at each side, 100 % H and 100 % M, respectively.

- Each side of the triangle represents all possible binary combinations of the three components.

- On any of those sides, the fraction of the third component is zero (0%).

- As you move from one side (0 %) to the 100 % or pure condition, the composition of the given component is increasing gradually and proportionally. At the very center of the triangle, we find 33.33 % of each of the component.

To differentiate within the two-phase region and single-phase region in the ternary diagram, pressure and temperature must be fixed. There will be different envelopes (binodal curves) at different pressures and temperatures. The binodal curve is the boundary between the 2-phase condition and the single-phase condition. Inside the binodal curve or phase envelope, the two-phase condition prevails. If we follow the convention given above (lights at the top, heavies and mediums at the sides), the two-phase region will be found at the top. This can be seen more clearly in Figure 5.7.

The binodal curve is formed of the bubble point curve and the dew point curve, both of which meet at the plait point. This is the point at which the liquid and vapor composition are identical (resembles the critical point that we studied before). Within the two-phase region, the tie lines are straight lines that connect the compositions of the vapor and liquid phase in equilibrium (bubble point to the dew point). These tie lines angle towards the medium-component corner. It can also be recognized that any mixture on a tie line has the same liquid and vapor compositions.

Finally, to find the proportion of liquid and vapor at any point on the tie line, we apply the lever rule.

Multicomponent Mixtures

For systems containing more than three components, pictorial representation becomes difficult, if not impossible. Simple diagrams can be obtained if the mole fractions of all but two or three components remain constant, and the variation of the two or three varying components with temperature and pressure are shown.

In practical applications, the mole fractions of all components can be expected to vary. For such systems, direct calculations based on physical models are the only way to obtain reliable information about the system phase behavior. This is the ultimate goal of this series of modules, and these calculations will be studied in detail as the course progresses.

Action Item

Answer the following problems, and submit your answers to the drop box in Canvas that has been created for this module.

Please note:

- Your answers must be submitted in the form of a Microsoft Word document.

- Include your Penn State Access Account user ID in the name of your file (for example, "module2_abc123.doc").

- The due date for this assignment will be sent to the class by e-mail in Canvas.

- Your grade for the assignment will appear in the drop box approximately one week after the due date.

- You can access the drop box for this module in Canvas by clicking on the Lessons tab, and then locating the drop box on the list that appears.

Problem Set

-

Figure 5.2 shows the P-T phase envelopes for eight binary mixtures of Methane and Ethane at eight different compositions. The data was experimentally generated at IGT (Institute of Gas Technology) and presented in the Research Bulletin No. 22. The vapor pressure curves of Methane and Ethane bound the phase envelopes of the eight binary mixtures of Methane and Ethane at different proportions. From left to right, these proportions (molar compositions) are:

P-T phase envelopes for eight binary mixtures of Methane and Ethane at eight different compositions Mixture Composition Mixture 1 97.50% CH4 and 2.50% C2H6 (closest to 100% pure Methane vapor pressure curve) Mixture 2 92.50% CH4 and 7.50% C2H6 Mixture 3 85.16% CH4 and 14.84% C2H6 Mixture 4 70.00% CH4 and 30.00% C2H6 Mixture 5 50.02% CH4 and 49.98% C2H6 Mixture 6 30.02% CH4 and 69.98% C2H6 Mixture 7 14.98% CH4 and 85.02% C2H6 Mixture 8 5.00% CH4 and 95.00% C2H6 (closest to 100% pure Ethane vapor pressure curve) Using this phase behavior data, generate the P-x and T-x diagram for Methane/Ethane mixtures at T = – 40 F and P = 500 psia respectively.

- If a certain amount of the mixture 40% C1 – 60% C2 is kept in a vessel at 500 psia, determine the temperature at which the vessel has to be subjected if at least 50% of the substance is required to be in the liquid state. How would your answer change if we were now required to have 10% of liquid in the vessel? How would it change if the overall composition is now considered to be 60% C1 and 40% C2 ?

- 10 lbmol of an equimolar C1/C2 mixture is confined inside a vessel at conditions of – 60oF and 500 psia. What is the percentage of liquid inside the vessel? What is the composition of the liquid and vapor at such condition?

- What would be the composition of the first bubble that appears in a isothermal expansion of a liquid at – 40oF? At which pressure would this bubble appear? What would be the pressure at which the first droplet appears in a isothermal compression of a vapor at – 40oF? What is the composition of such a droplet?

- Can you apply the lever rule to in a ternary diagram? If not, why not? What about a multicomponent system?

PT Behavior and Equations of State (EOS), Part I

Module Goals

Module Goal: To introduce you to quantification in fluid phase behavior.

Module Objective: To quantitatively and qualitatively compare ideal and real gas behavior.

Introduction

The ultimate purpose of this course is to build a firm knowledge of the phase behavior of fluids. With this understanding, we will be able to establish the basis and rationale upon which phase behavior applications in production systems are grounded. We are using the word production in a generic sense, that is, where it pertains to reservoir, pipeline, and the surface production (of any produced fluid).

So far, we have seen that much of the importance that we place on understanding phase behavior comes from the ability that it gives us to predict how a given system will behave at different conditions. We need phase diagrams to look at what the state of the system that we are dealing with is; that is, what is its original state. As a matter of fact, if we look at petroleum production, we often talk about a thermodynamic process that is taking place, involving a process path similar to one that we have seen in any basic thermodynamics course.

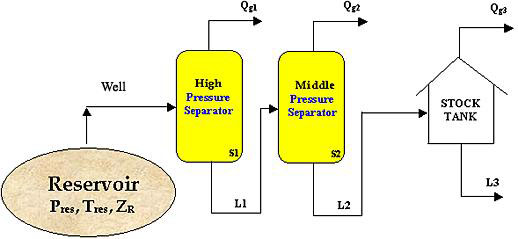

Just to give an illustration, consider Figure 6.1.

Production, as defined above, involves taking the reservoir from an initial condition (PA , Tf) to final state of depletion (PB , Tf), (PD , Tf), (PE , Tf) or even (PF , Tf). Once the end points of our thermodynamic path are fixed, the single most important question is determining the path that leads to such an end point. This path dictates whether or not you have the maximum recovery possible from the system.

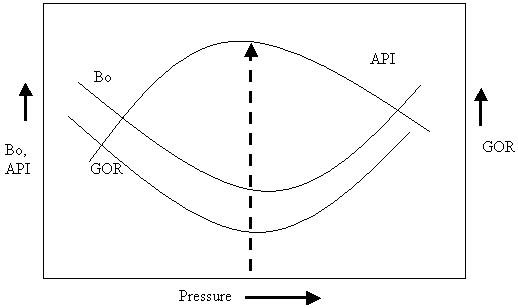

When we talk about gas cycling, we are generally referring to the practice of injecting gas back into the reservoir. This is done in order to optimize the thermodynamic path we have chosen to take. In a typical condensate system, you generally produce a wet gas from the system with a high liquid yield at the surface. At the surface, you pass this gas through a series of separators; during this process liquid is going to drop out. The liquid that drops out will be rich in the heavier components. Hence, the gas that comes out of the separator will be dry (i.e., very light). If you inject this lean gas back into the reservoir, there will be a leaching process. All you are trying to do from the point of view of the phase diagram is to move the phase boundary and dew point towards the left (lower temperatures zones). Let me explain this in more detail.

Let us say that we have the phase envelope for the reservoir fluid shown in Figure 6.1, with the given path of production. If we were to follow the path from (A , Tf) to (E , Tf), we would enter the two-phase region and end up having liquid in the reservoir. However, you do not want liquid in the reservoir because its low mobility dictates that it would not be recovered! Next, you want to move that phase diagram to the left by injecting a lighter gas. When you inject a lighter gas, the phase envelope shifts to the left; your production path will be free of liquid dropout at reservoir conditions. By injecting the gas, we are making the overall composition of the reservoir fluid lighter. The effect of composition on phase behavior was discussed in the previous module (see Figure 5.2 in Module 5). This example demonstrates the importance of phase diagrams as tools that help us produce a reservoir in an optimal way.

So, we recognize that we needed phase behavior data for this particular system. The question now is how do we get the data? We can collect data in at least two ways: from laboratory measurements and from field measurements. Lab experiments are expensive, and we cannot hope to generate data for every foreseeable condition we may encounter. Just to give you an idea, generating a single phase envelope may cost at least $120,000. This is not something you want to be doing all the time. On the other hand, if you went to the field, you would lose valuable resources or have to stop operations to make your observations. On a routine basis, you don’t want to use the field or a lab as your main sources of phase behavior data. These options mean a lot of lost revenue and a great deal of expense. Is there a third option? Yes, indeed. We can rely on prediction, by which we produce a model that can do this work for us. In fact, we will be dealing with, and developing, this option in this course.

The basis for such a model is what is called an Equation of State (EOS). Hence, the central part of this course is EOS, since they are the basis of what we do in phase behavior.

There are several other examples that illustrate very vividly why we need to study equations of state. For instance, let us think about the concept of equilibrium.

In petroleum production, we generally make the assumption that, at every stage, the system is in equilibrium. When you think about equilibrium, you generally think about a system that is static, that is, not moving. When a system is moving, it cannot, in actuality, be in equilibrium. Nevertheless, the best approach we have so far is to describe it using equilibrium thermodynamics. While we usually assume equilibrium, we recognize that it is not a perfect assumption, but that it is a reasonable one.

This means that in the course of producing the reservoir, a process which always involves movement, I am assuming that everywhere the gas and the liquid are in equilibrium. With this assumption, we are free to use equilibrium thermodynamics, so we are able to employ EOS in describing the state of the system.

Consider the reservoir in Figure 6.1, in an entirely gaseous condition at (A, Tf), and having a known fluid composition zri (i=1,…n). As we produce this reservoir through a pipeline, we take the fluid from reservoir conditions through a battery of separators. Generally speaking, we deal with a series of separators, but for the sake of this discussion we will assume that we have just a single separator.

This separator does not care about the pressure and temperature of the reservoir. It only cares about its own pressure and temperature condition: Ps, Ts. The composition of the fluid at the separator inlet is assumed to be the same as that of the reservoir fluid, although this is strictly true only for single phase conditions.

The fluid exits the separator in two streams: a vapor stream and a liquid stream. As a petroleum engineer, we want to know how much gas, how much liquid, and the quality (compositions) of both streams. That is, we need quantitative and qualitative information. As we shall study in Module 12, we can perform a material balance around each separator to calculate the amount of vapor and liquid that is to be recovered. We will need the properties of both streams (such as density and molecular weight) in order to express flow rates in suitable field units.

How do we generate all this? We need a tool; that tool is an Equation of State! Why do we need an Equation of State? We need EOS to define the state of the system and to determine the properties of the system at that state. That is why it is called an equation of state. As you may have noticed, something critical in this series of lectures is the ability to establish links within all the material we are studying. We will not look at each topic simply as an isolated compartment, but instead, we must think in terms of how each piece of information fits into the overall picture that we are developing.

P-V-T Behavior

We embark now on a rather ambitious journey. Given a fluid, we would like to develop mathematical relationships for predicting its behavior under any imaginable condition of pressure, temperature and volume (P-V-T). In other words, we want to describe the P-V-T behavior of fluids in general.

As we stated earlier, this is a very challenging problem. The way science approaches these sorts of problems is to introduce simplifications of the physical reality. In other words, we formulate a set of assumptions and come up with a base model that we might call ideal. From that point on, once the base model has been established, we look at a real case by estimating how close (or far) it performs, with respect to the base (ideal) case, and introducing the corresponding corrections. Such corrections will take into account all the considerations that our original assumptions left out.

Let us discuss our base case for fluids (the simplest fluid we may deal with): the ideal or perfect gas.

Ideal Behavior

An ideal gas is an imaginary gas that satisfies the following conditions:

- Negligible interactions between the molecules,

- Its molecules occupy no volume (negligible molecular volume),

- Collisions between molecules are perfectly elastic — this is, no energy is lost after colliding.

We recognize that this fluid is imaginary because — strictly speaking — there are no ideal gases. In any fluid, all molecules are attracted to one another to some extent. However, the ideal approximation works best at some limiting conditions, where attraction forces can be considered to be weak. In fact, ideal behavior may be approached by real gases at low pressures (close to atmospheric) and high temperatures. Note that at low pressures and high temperatures, the distance between any pair of gas molecules is great. Since attraction forces weaken with distance, we have chosen a condition where attraction forces may be neglected. In conclusion, we consider a gas ideal when each molecule behaves as if it were alone — molecules are so far apart from each other that they are not affected by the existence of other molecules.

The behavior of ideal gases has been studied exhaustively and can been extensively described by mathematical relationships.

For a given mass of an ideal gas, volume is inversely proportional to pressure at constant temperature, i.e.,

(6.1)

This relationship is known as Boyle’s Law. Additionally, volume is directly proportional to temperature if pressure is kept constant, i.e.,

(6.2)

This relationship is known as Charles’ Law. By combining both laws and recognizing “R” (the universal gas constant) as the constant of proportionality, we end up with the very familiar equation:

< (6.3)

This represents the equation of state (EOS) of an ideal gas. Numerical values of “R” depend on the system of units that is used:

If we construct the P-v diagram for an ideal gas at a given temperature, we end up with the isotherm shown in Figure 6.2.

The ideal gas model predicts two limiting fluid behaviors: first, that the volume of the gas becomes very large at very low pressures as , a concept that agrees with what we know from our experience in the physical world). And second, as (the volume of matter just “vanishes” if the pressure is high enough: this concept we would not be as willing to accept). These two behaviors are a consequence of the assumptions made in the ideal gas model.

Real Gases

In reality, no gas behaves ideally. Therefore, the ideal EOS is not useful for practical applications, although it is important as the basis of our understanding of gas behavior. Even though the ideal model is not reliable for real engineering applications, we have to keep in mind that the ideal gas EOS is the starting point of all modern approaches.

If we look back at Figure 6.2 and recall our discussions about P-v behavior of pure substances, something should catch your attention. Figure 6.3 shows us the typical P-v behavior of a pure substance to facilitate our discussion.

What can we conclude about the ideal EOS while contrasting Figure 6.2 to 6.3? The curve in Figure 6.2 is continuous; Figure 6.3 has an obvious discontinuity (at the vapor+liquid transition). Hence, one thing we can already say is that the ideal EOS is at least qualitatively wrong. For a real substance, as pressure increases, there must be a point of discontinuity that represents the phase change. Ideal gas will not condense, no matter what pressure it is subjected to, regardless of the temperature of the system. In other words, we cannot hope to reproduce the P-v behavior of Figure 6.3 using the ideal equation (6.3) since no discontinuity is to be found. However, the real P-v isotherm can be approximated by ideal behavior at low pressures, as we can see from the plots.

We can also establish some quantitative differences between ideal and real PVT behavior. For example, for most conditions of interest at a given volume and temperature, the ideal gas model over-predicts the pressure of the system:

(6.4)

We can explain this difference by recalling that a real gas does have interaction forces between molecules. Secondly, we recall that the concept of “pressure” of a gas is a consequence of the number of molecular collisions per unit area against the wall of the container. Such number of collisions is, in turn, a measure of the freedom of the molecules to travel within the gas. The ideal gas is a state of complete molecular freedom where molecules do not even know the existence of the others. Hence, a hypothetical ideal gas will exert a higher pressure than a real gas at any given volume and temperature. When molecules come together (real gas), it reduces the available free space for the molecules and pressure is reduced.

Additionally, the ideal model assumes that the physical space that the molecules themselves occupy is negligible. In reality molecules are physical particles and they do occupy space. Once we find a way of accounting for the space that the molecules themselves occupy, we would be able to compute a “real” free volume available for the molecules to travel through the gas. In the ideal case, this free volume is equal to the volume of the container itself since molecular volume is not accounted for. In the real case, this free volume must be less than the volume of the container itself after we account for the physical space that molecules occupy. Therefore:

(6.5a)

(6.5b)

Summary

The ideal gas EOS is inaccurate both quantitatively and qualitatively. Quantitatively, ideal gas will not condense no matter what pressure and temperature the system is subjected to. Quantitatively, pressures and volumes used by the ideal gas model are higher than the values that a real gas would have. These are the primary reasons that scientists have made an effort to go beyond the ideal gas EOS, simply because it does not apply for all the cases of interest.

Action Item

Answer the following problems, and submit your answers to the drop box in Canvas that has been created for this module.

Please note:

- Your answers must be submitted in the form of a Microsoft Word document.

- Include your Penn State Access Account user ID in the name of your file (for example, "module2_abc123.doc").

- The due date for this assignment will be sent to the class by e-mail in Canvas.

- Your grade for the assignment will appear in the drop box approximately one week after the due date.

- You can access the drop box for this module in Canvas by clicking on the Lessons tab, and then locating the drop box on the list that appears.

Problem Set

-

Under what conditions should a real gas behave as an ideal gas?

-

Can we manufacture an ideal gas?

- Write a paragraph on what you think we should do with the ideal gas equation to make it applicable to real gases. Describe all the considerations that you feel must be accounted for.

PT Behavior and Equations of State (EOS), Part II

Module Goals

Module Goal: To introduce you to quantification in fluid phase behavior.

Module Objective: To introduce you to the concept of Z-factor and the van der Waals equation of state.

Z-Factor

From the last module, it is very likely that one question is left in our minds. How can we adjust the ideal model to make it suitable for real gases? Well, we already have the answer. We said that once we have established a base (ideal) model, we look at a real case by estimating how close (or far) it performs with respect to the base (ideal) case, and introducing the corresponding corrections. Again, such corrections will take into account all the considerations that our original assumptions left out.

For the case of gas behavior, we introduce a correction factor to account for the discrepancies between experimental observations and predictions from our ideal model. This correction factor is usually referred to as the compressibility factor (Z), and is defined as:

(7.1)

In the previous equation, V is the real volume occupied by the gas and VIdeal is the volume that the ideal model predicts for the same conditions. The ideal volume is given by:

(7.2)

Hence, the equation of state for real gases is written as:

(7.3)

Engineers are very much familiar with this equation, to the extent that it is usually recognized as Engineering EOS. Please note that for Z = 1, this equation collapses to the ideal gas model. In fact, unity is the compressibility factor of any gas that behaves ideally. However, please note that Z = 1 is a consequence of ideal behavior, but this is not a definition.

Something to think about:

Is it possible to have a real gas at a condition at which Z=1 without being ideal (far removed from the ideal-gas theory assumptions)?

For natural gases, the most enduring method of estimating Z has been the Katz-Standing Method. However, we are now living in a computer-driven era, where thermodynamic estimations are very rarely taken from graphs or plots, as was common in the past.

Definition of Equation of State (EOS)