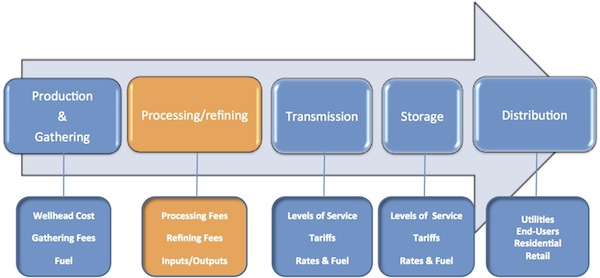

Having made the necessary gathering connections, raw natural gas needs to be purified of all contaminants and inert gases and have heavy hydrocarbons removed to make it safe for commercial use. This takes place at a processing plant where the resultant residue gas is almost 98% pure methane and is what is known as “marketable” natural gas. In addition, processing plants remove the more volatile hydrocarbons, or “natural gas liquids,” (NGLs) which can then be sold separately. This is also a safety issue; end-users of natural gas cannot have more than methane in their supply because explosions could occur.

The following mini-lecture walks through each step of this process and explains the nature of natural gas liquids (NGLs) in detail.

Key Learning Points for the Mini-Lecture: Processing and Natural Gas Liquids (NGLs)

While watching the Mini-Lecture, keep in mind the following key points and questions:

- Natural gas coming out of the ground is in a very "raw" state.

- Processing plants remove heavy hydrocarbons and purify the gas stream for end-use consumption.

- Processed natural gas is known as "commercial grade," or "marketable," gas.

- There are several natural gas liquids (NGLs) that can be extracted from natural gas.

- NGLs vary in molecular structure and have varied uses.