Frame and Spacer Materials

Window frames are available in a variety of materials including aluminum, wood, vinyl, and fiberglass. Frames may be primarily composed of one material, or they may be a combination of different materials such as wood clad with vinyl or aluminum-clad wood. Each frame material has its advantages and disadvantages, as shown in the table below.

| - | Advantages | Disadvantages | How to Improve |

|---|---|---|---|

| Aluminum | Ideal for strength and customized window design | Conduct heat and therefore lose heat faster and are prone to moisture condensation. | Anodizing or coating will prevent corrosion and electro-galvanic deterioration of aluminum frames; thermal resistance can be improved by placing continuous insulating plastic strips between the interior and exterior frame. |

| Wood | Have higher R-values, are not affected by temperature extremes, and do not generally promote moisture condensation. | Require considerable maintenance in the form of periodic painting or staining. If not properly protected, wood frames can swell, which leads to rot, warping, and sticking. | |

| Vinyl (typically polyvinyl chloride (PVC) | Available in a wide range of styles and shapes, have moderate to high R-values, are easily customized, are competitively priced, and require very low maintenance. | Do not possess the inherent strength of metal or wood. | Larger-sized windows are often strengthened with aluminum or steel reinforcing bars. |

| Fiberglass | Some of the highest R-values; excellent for insulating; will not warp, shrink, swell, rot, or corrode. | Relatively new and are not yet widely available. Unprotected fiberglass does not hold up to the weather and therefore is always painted. |

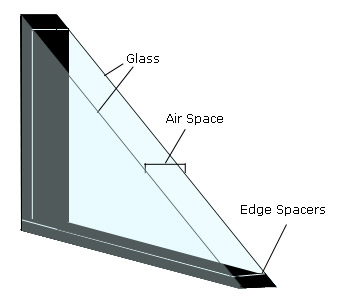

Spacers are used to separate multiple panes of glass within the windows. Although metal (usually aluminum) spacers are commonly installed to separate glass in multi-pane windows, they conduct heat.

During cold weather, the thermal resistance around the edge of a window is lower than that in the center; thus, heat can escape, and condensation can occur along the edges.

Problems with Spacers

The following have been done to alleviate the problems associated with spacers:

- One manufacturer has developed a multi-pane window using a 1/8-inch-wide (0.32 centimeters-wide) PVC foam separator placed along the edges of the frame. Like other multi-pane windows, these use metal spacers for support, but because the foam separator is secured on top of the spacer between the panes, heat loss and condensation are reduced.

- Several window manufacturers now sandwich foam separators, nylon spacers, and insulation materials such as polystyrene and rockwool between the glasses inside their windows.

- A new type of spacer product called warm-edge technology has evolved in the industry to overcome the thermal inefficiency of conventional aluminum spacers. Warm-edge refers to the type of spacer material used to separate the panes of glass (or glazing) in an insulated window unit. If the material conducts less heat or cold than a conventional aluminum spacer at the edge of the glass, it is said to be "warm-edge." Most of these newer spacers are less conductive and outperform pure aluminum. But still they all contain some kind of metal. And metal is highly conductive.

- Available in the market is a NO-metal Super Spacer, which uses no metal and is made up of 100 percent polymer structural foam. Therefore, it is believed to improve the R-Value of the whole window and reduce moisture condensation problems.

Selecting Main Parameters of Windows

General guidelines for selecting the main parameters of windows based on the climate are provided in the table below.

| - | Colder climate | Moderate Climate | Warm Climate |

|---|---|---|---|

| U-Factor | Less than 0.33 | 0.33 | 0.33 |

| Visual Transmittance | 50 percent | >50 percent | >60 percent |

| SHGC | 0.4-0.55 | >0.55 | <0.4 |

| UV-Protection | >75 percent | 75 percent | 75 percent |

| Edge Spacers | Super Spacers | Warm edge spacers | Warm edge spacers |

| Frame | Non-conductive | Non-conductive | Non-conductive |

| Air leakage | <0.3 cfm/sq.ft | <0.3 cfm/sq.ft | <0.3 cfm/sq.ft |

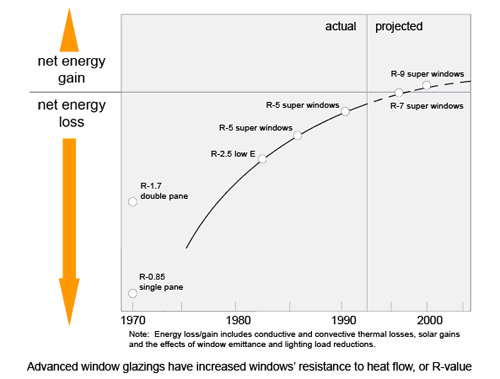

Improvement in Window Performance

The image below shows the improvement in window performance (R-value) with advanced window glazing. It can be seen from the figure that the super windows are losing less heat and are even making progress to gain heat instead of losing heat because of solar heat gains.