In my experience in this course, students have difficulty understanding the difference between materials scientists and materials engineers. In the reading for this lesson, materials science is defined as investigating relationships between structures and properties of materials, and concern with the design/development of new materials. Materials engineering is defined as the creation of products from existing materials in the development of new materials processing techniques. I would restate the roles of material scientists and materials engineers as:

- Materials scientists study materials and create new materials.

- Materials engineers use materials and create new processes.

Now, these statements of the roles for material scientists and engineers are, of course, oversimplifications. As I think you will see in the following video (5:34) produced by the Penn State Department of Materials Science and Engineering we believe that cutting-edge materials research and development require a thorough understanding of both materials science and engineering.

To Watch

GARY L. MESSING: Materials Science and Engineering at Penn State is one of the larger departments of Materials Science in the country. By virtue of that we are able to offer a full spectrum of research and teaching in the field of materials. We're strong in all aspects of materials - ceramics, metals, polymers, composites, semi-conductors. That brings a certain uniqueness to the education of a Penn State graduate.

R. ALLEN KIMEL: We've tried to basically give the students a very strong core into the fundamentals of Materials Science and Engineering which are structure, property, relationships, but because of the breadth and depth of the expertise in this department they can choose to take courses that go towards interest which brought them here in the first place. They could choose to focus in biomaterials or they could choose to focus in energy - it really allows a student to make their own Materials Science and Engineering degree.

ANGELA LEONE: Being at Penn State you get the large university feel where you are one in thousands of students at the same time you get the experience of the small college where everyone in the Materials department knows you by name. I'm currently studying the corrosion of nuclear waste glass fibers with Dr. Pantano. I found out that he's studying glass and I'm really interested in glass. So I just set up a meeting with him and about a week later he was showing me his labs. I think the most special thing I've done is to get involved in glass blowing. I really enjoying doing it it's very unique and I don't think I'd have that experience anywhere else. A lot of the professors look for undergrads to do research for them, to give them a feel and it helps you choose if you want to go on to grad school or go into industry.

JAME ADAIR: At any given time I'll have four to six undergraduates working in my laboratory right now i have about six. I bring both my research into my lectures for the undergraduates and my lectures into my research. The curriculum focuses on cutting edge technology We also run a very strong research experience for undergraduate programs - it's a summer science program where we bring in undergraduates from all over the United States, including Penn State, into our laboratories. We're at the cutting edge in terms of early detection of cancer and much more benign delivery chemotherapeutics, as well as a host of new surgical instruments based on our ceramic powder processing.

R. ALLEN KIMEL: We even take it beyond the department and this country have our own international internship program. We have relationships with fourteen different universities in Europe and Asia and we send our students there to join research groups for a semester and actually perform research - so it's not a study abroad, take classes, but it's actually going there with a research question in mind and then joining a research group and actually performing that research. So it's getting involved in the research enterprise - and it's global.

STEPHEN WEITZNER: I've traveled to Germany with the department's International Internship in Materials Science Program. That was great, I was in Germany for seven months doing research at the Technical University of Darmstadt, where I was also doing some work with computational modeling and provided a nice background for coming back to campus and starting my senior thesis.

GARY L. MESSING: Materials at Penn State is actually a very big enterprise not only do we have the Department of Materials Science and Engineering, but we also have the Materials Research Institute The Institute represents all of the faculty on campus that are working in the field of materials. The Institute brings the strength of community as well as the research facilities.

MICHAEL HICKNER: At Penn State, we have great opportunities for high-level research in Materials Science. Penn State has a long history in solving real-world problems in industry, we have over a hundred million dollars of research that the entire university does with companies per year and we work with both large companies like General Electric and Dow Chemical Company as well as small startup companies either in State College or in Silicon Valley, and so I think that the research and the ideas here are flexible. We have a lot of unique capability.

JOAN REDWING: The research that we are doing at Penn State in the area of low dimensional materials is impacting the field of material science by providing new routes for the synthesis of low dimensional materials and also providing new insights into how these materials behave and ultimately how we can integrate them into devices. It feeds into other activities here at Penn State that are focused on on the fabrication of devices so their faculty members in Electrical Engineering who are using the low dimensional materials to fabricate transistors or other types of electronic devices.

MICHAEL HICKNER: The of material science that we do at Penn State is really creating new opportunities and pushing new frontiers in material science. Our research that we do in our labs everyday makes a big difference to new types of batteries or new types of medical devices or new types of structural steels that had better corrosion resistance, or are harder, or more ductile. And so I think that we both make a difference in real-world problems, but also, we open up new ways to think about science and new ways to think about materials.

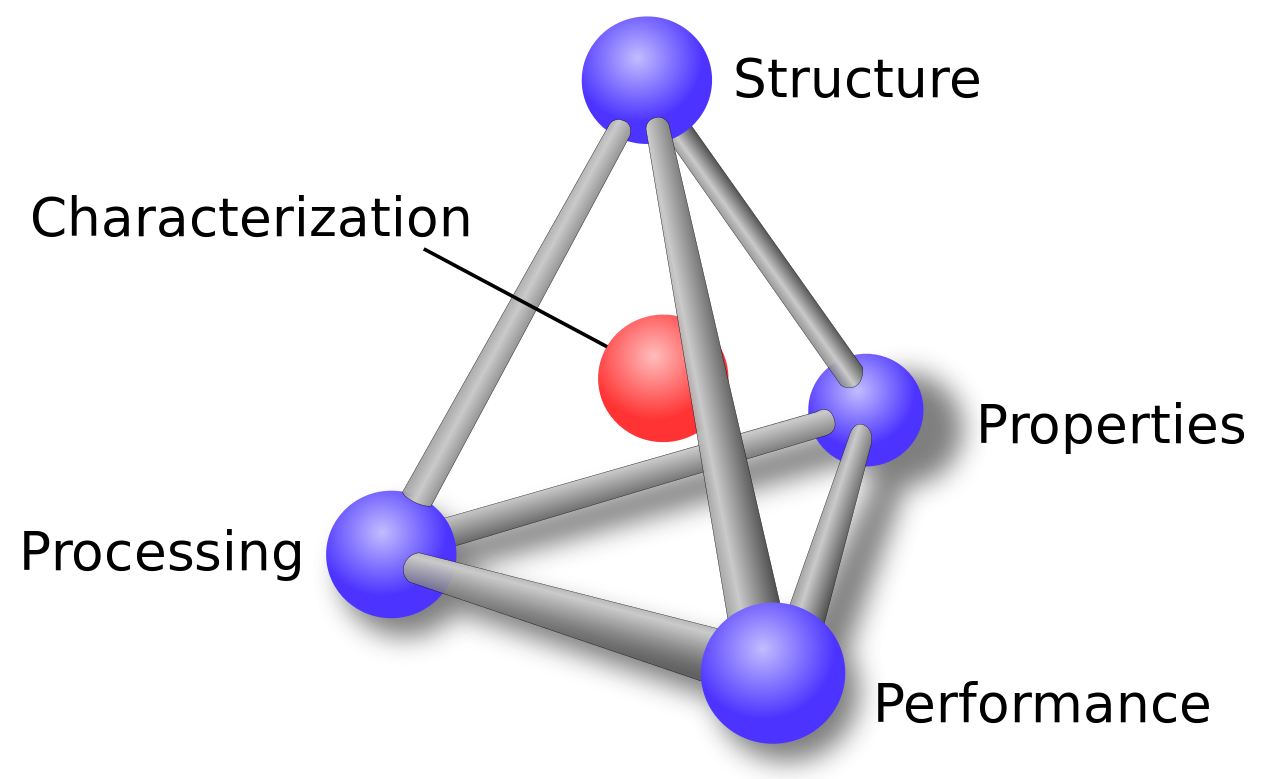

When utilizing a material, one needs to understand that the structure, properties, processing, and performance of the material are interrelated. This is represented by the materials science tetrahedron shown in the figure above. If one alters the processing, there is a direct connection with the structure, properties, and performance of the material. Adjusting any one of the factors will have varying degrees of impact on the other three factors. Characterization is the heart of the tetrahedron, signifying its role in monitoring the four components.

In this course, we will be looking at the four components (structure, properties, processing, and performance) of materials, beginning with properties. Properties of materials can be classified into six categories: mechanical, electrical, thermal, magnetic, optical, and deteriorative. We will start by looking at mechanical properties in lesson four and electrical properties in lesson 12. Unfortunately, we will not have time in this course to look at the other four properties. In lessons 3, 5, 7, and 8 we will look at structure, both atomic and micro-structure. Lesson 10 will be concerned with the processing of materials, and performance of material will be addressed throughout the course.