Most of the energy used by a refrigerator is used to pump heat out of the cabinet. A small amount is used to keep the cabinet from sweating, to defrost the refrigerator, and to illuminate the interior.

The efficiency of a refrigerator is based on the energy consumed per year for a given size. The efficiency of a refrigerator is expressed in volume cooled per unit electric energy per day. Volume is measured in cubic feet and electrical energy is measured in kilowatt-hours.

Refrigerator Efficiency = Volume Cooled (ft3) / Unit Electrical Energy per day (KWh)

The energy efficiency of refrigerators and freezers has improved dramatically over the past three decades. For example, the energy bill for a typical new refrigerator with automatic defrost and top-mounted freezer will be about 55 dollars / year, whereas a typical model sold in 1973 will cost nearly 160 dollars / year (almost three times the energy consumption).

The Department of Energy (DOE) standards set maximum allowable annual energy consumption for different sizes and classes of refrigerators. These Federal efficiency standards first took effect in 1993, requiring new refrigerators and freezers to be more efficient than ever before. A new set of stricter standards took effect July 1, 2001.

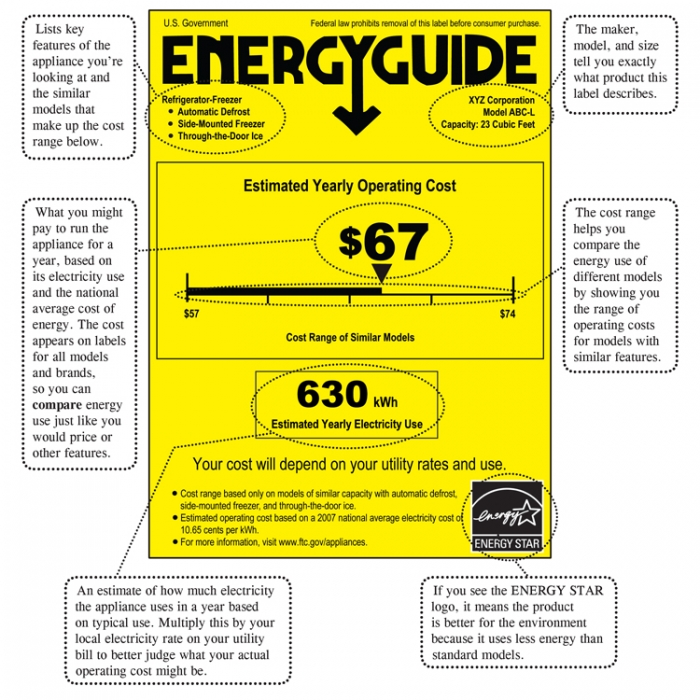

Energy Guide Labels

Refrigerators now come with an EnergyGuide label that tells you in kilowatt-hours (kWh) how much electricity a particular model uses in a year. The smaller the number, the less energy the refrigerator uses and the less it will cost you to operate.

- Full-sized refrigerators that exceed the federal standard by 15% or more (and full-sized freezers that exceed it by 10%) qualify for the ENERGY STAR label.

- Compact refrigerators and freezers must exceed the standard by 20% to qualify for ENERGY STAR.

ENERGY STAR qualified refrigerators provide energy savings without sacrificing the features you want. ENERGY STAR–qualified models have

- High-efficiency compressors

- Improved insulation

- More precise temperature

- More precise defrost mechanisms

These models also use at least 15% less energy than required by current federal standards, and 40% less energy than the conventional models sold in 2001.

Many ENERGY STAR qualified models include automatic ice-maker and through-the-door ice dispensers. Qualified models are also available with top, bottom, and side-by-side freezers.

What to look for in a Refrigerator

When selecting a refrigerator, remember the following:

- Refrigerators with the freezer on either the bottom or top are the most efficient. Bottom freezer models use approximately 16 percent less energy than side-by-side models, and top freezer models use about 13 percent less than side-by-side.

- Through-the-door ice makers and water dispensers are convenient and reduce the need to open the door, which helps maintain a more constant temperature; however, these convenient items will increase your refrigerator's energy use by 14 to 20 percent.

- Mini-doors give you easy access to items most often used. The main door is opened less often, which saves energy.

- Too large a refrigerator may waste space and energy. One that's too small can mean extra trips to the grocery store. Your best bet is to decide which size fits your needs, and then compare the EnergyGuide label on each, so you can purchase the most energy efficient make and model. (filling your refrigerator helps with efficiency, so long as it's not overfilled!)

- A manual defrost refrigerator uses half the energy of an automatic defrost model, but must be defrosted regularly to stay energy efficient.

- Refrigerators with anti-sweat heaters consume 5 percent to 10 percent more energy. Look for models with an "energy saver" switch that lets you turn down—or off—the heating coils (which prevent condensation).

Technology Improvements

The improvement in the energy efficiency over the past three decades is due to the:

- addition of vacuum insulation panels around the freezer section to reduce heat transfer;

- addition of polyurethane foam to the doors to double insulation thickness;

- replacement of AC motors with more efficient DC motors;

- replacement of automatic defrost control with an adaptive defrost that operates only when needed.