Please watch the following video: 4:47

PRESENTER: In Pennsylvania, we're very fortunate to have many different sources of energy, some of them renewable, some of them non-renewable. In fact, every geographic province of the state has access to a wide variety of different types of energy and different ways in which we can complete a pretty well-balanced pie with the different options that were presented. However, it is very easy to become a little bit complacent when we're talking about renewables and look at the end game, instead of looking at what the individual steps that takes us to producing energy do.

So in this module, we're going to be talking about life cycle analysis. In life cycle analysis, we break out the different parts of the system in a way in which the inputs and outputs of each one of the steps are going to be easily measurable. For example, when you think about production of hydropower, you think about a lot of its positive. You know that there is basically no carbon emissions, and you know that it's renewable. And you know that, in some ways, you're not affecting the water in the dam to a very large extent.

But you're ignoring a number of other possibilities. And you're ignoring things like the effect of sedimentation behind the dam or the effect that putting that kind of discharge will have in the biota of the water downstream.

You're also ignoring many social aspects. In particular, in this dam, a Native American population was displaced in order to build it. Therefore, being able to see this area as a system and putting on the life cycle analysis along with the other components of economic and social analysis, will give us a much better picture of what we're getting for our renewables.

This stream has been exposed to extensive acid mine drainage, as you can see. So that brings us to an end of the pipe solution, quite literally. And one of the main questions that we face when we try to remediate a system that has been extensively disturbed, is what is it that we're trying to achieve?

What is our ultimate goal? Do we want to return this system to its original state? And if that is our goal, what is that original state that we're searching for?

We can also take a more pragmatic approach and decide that we want to just basically clean up and remediate, get rid of the major contaminants, get rid of whatever hazardous materials that might be present. But even under those conditions, we face the challenge that this maintenance needs to occur in a long-term perspective.

So if we think about different companies coming and extracting some of these resources, many of those companies are not able to commit to cleaning up and to maintain the local environment in the long-term. So a lot of these responsibilities end up falling in the hands of the government. And the long-term management has also been something that has been managed by governments, as a general rule.

Clearly, this needs to change, and this changes, through application of life of cycle analysis, where you're understanding the consequences of each one of the different processes that are taking place in the chain of production from the time of extraction to the time that you're disposing your product, and the fact that you might have many different endpoints, depending on how many different sources of materials and services you are needing in order to produce a certain end result.

In Module 2, we discussed the challenges faced while trying to assess the degree to which sustainability has been attained for a large system. The larger and more complicated a system is, the greater the challenge to create meaningful ways to measure it. In response to these challenges, we can use the Mess-Problem and thermodynamics frameworks to define product systems and to follow them from the initial stages in which raw resources are extracted from natural systems to end-of-life management. We term this period as the Life Cycle of a product.

Stages of the life cycle of a product

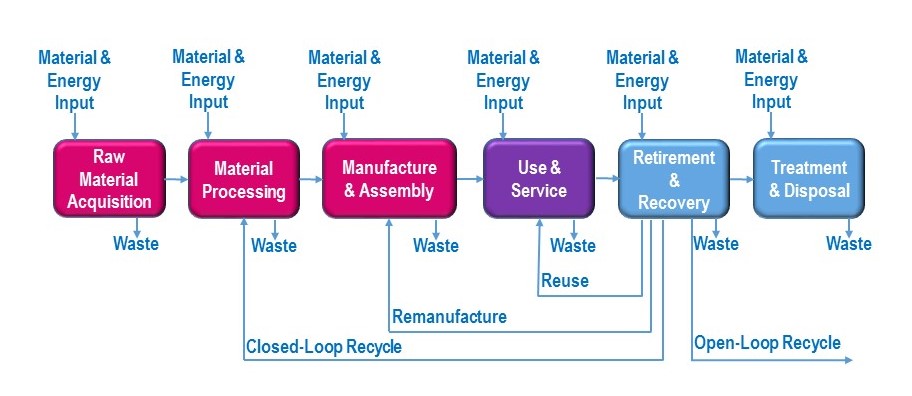

This image shows a series of stages in the life cycle of a product. From left to right, the stages are as follows:

- Raw Material Acquisition

- Material Processing

- Manufacture & Assembly

- Use & Services

- Retirement & Recovery

- Treatment & Disposal

Into each stage is fed Material and Energy, and output from each stage is Waste.

A Closed-Loop Recycling process may include output from the Retirement & Recovery stage that is put into the Material Processing stage.

A Remanufacturing process may include output from the Retirement & Recovery stage that is put into the Manufacture & Assembly stage.

A Reuse process may include output from the Retirement & Recovery stage that is put into the Use & Service stage.

An Open-Loop Recycling process may include output from the Retirement & Recovery stage that is sent elsewhere for use.

The different stages of this life cycle are shown above, in Figure 4.1. In this figure, inputs, outputs, and relationship among the different stages of the life cycle are shown. Traditionally, the flow of materials and energy progresses in a nearly linear fashion, with virgin raw materials in one end and disposal out the other end. Some treatment and mitigation may occur at the very end of the life of the product. This approach is commonly known as end-of-the-pipe. If recycled materials are re-incorporated into the processing stage, the cycle becomes shorter, indicating environmental gains. Larger gains are obtained from remanufacturing. Finally, the largest environmental gains are made by reusing. The other end-member of recycling is open-loop recycling, in which materials that have been collected, sorted, and in many cases purified, are not re-incorporated into the production loop. Instead, they often end up in landfills. The reason for this large waste of resources generally has to do with recycled materials not being economically competitive if compared with virgin, raw materials.

Life Cycle Analysis (LCA) of a product system follows and connects the different material and energy flows from a material's production, to manufacturing, use/service, and finally to disposal, as represented in the figure below.

- Transparency in the methodology.

- Scientific confidence and co-operation.

- Development of recommended factors and methodologies with uncertainty described.

- Development of methodology for impact categories with specific relevance for developing countries (salinisation, erosion, soil depletion).

The focus of an LCA is preeminently environmental - economic and social implications are outside the scope of this tool. Because of this focus, data collected as part of an LCA come from the physical and life sciences.

After its development in the 1960-1970, LCA has become a method widely implemented by industry in developed countries. Attempts to disseminate this technique to developing countries have been pioneered by the United Nations. In 2002, the United Nations launched the Life Cycle Initiative under the Program for Sustainable Consumption. This program aims: "To develop and disseminate practical tools for evaluating the opportunities, risks, and trade-offs associated with products and services over their whole life cycle."