5.4. Management of food waste and composting technologies

Food waste accounts for 14.5% of all generated waste in the US according to EPA report, and only a small portion of it is recovered (1.6%). At the same time, food waste contains loads of nutrients that can be returned to the environment, but it should be done the right way. Disposing of the organic waste in the landfill results in the generation of methane, which can pose a threat or contribute to the greenhouse effect. Hence, developing composting technologies is an important part of a sustainable waste management system.

Compost is a stable organic mixture resulting from the breakdown of organic components; it is typically dark brown or black and contains humus which provides a soil-like, earthy smell. Compost is widely used as fertilizer and soil amendment in agriculture. It is created by piling organic wastes (garden waste, leaves, food waste, manure) with bulking agents (e.g., wood chips) to provide an environment for anaerobic bacteria and fungi to manage the chemical decomposition process. Compost is stabilized through maturation and curing process.

According to US EPA, there are a number of benefits of the composting process. These include:

- reduction and elimination of the need for chemical fertilizers;

- increasing of crop yields;

- facilitation of reforestation, wetland restoration, and habitat revitalization by amending contaminated, compacted, and marginal soils;

- cost-effective remediation of soils contaminated by hazardous waste;

- absorption and removal of solids, oil, grease, and heavy metals from stormwater runoff;

- avoidance of methane and leachate formation in landfills;

- decreased need for water, fertilizers, and pesticides in agriculture;

- serving as a marketable commodity and as a low-cost alternative to standard landfill cover;

- capturing and destruction of 99.6 percent of industrial volatile organic chemicals (VOCs) in contaminated air;

- more cost-effective soil, water, and air remediation compared to conventional technologies;

- extension of municipal landfill life by diverting organic materials from landfills.

Certain physical conditions need to be provided for proper composting process. There are different types of processes, which are overviewed in the following reading.

Reading Assignment:

EPA Website: Types of Composting, US Environmental Protection Agency, 2013.

Watch this short video that illustrates an industrial-scale composting facility in the UK. This is only one of the ways to do it. Which type of composting (from those listed by EPA) is this facility using?

Video: Hi-Tech Composting Plant (5:40)

LEON MEKITARIAN: Organic recycling is a mucky business. There's no point in being precious about it, yeah? It's dirty. It's smelly. It's basic. It's elemental. Linking what we do back to agriculture is nothing new. The Norfolk four course rotation, on which agricultural fertilizing has been founded since time immemorial, is based on returning organic manures and materials to land as fertilizers. We just got lazy in the last 40 years and bought them from an oil pipeline instead. Currently, food waste is rejected from restaurants, hotels, school canteens, and the kitchen table, put into the domestic refuse bag, and taken away and sent to landfill. Food waste in landfill generates methane. Methane is 18 times more damaging to the ozone layer than CO2 emissions. So every kilogram of food waste that ends up in landfill has the potential to dramatically increase greenhouse gases. Recycling of food waste is one of the most important things you can do. It's better for the environment than changing your car for a hybrid. The great thing about this process is it's self-heating. It's called autothermal thermophilic aerobic digestion. That's a bit of a mouthful. It basically means it's a self-heating compost heap. So, we use minimal energy here and let the bugs do all the work. This is a controlled natural reaction. All we're doing is capturing that reaction, harnessing it, and supercharging it. This plant operates at 75 degrees centigrade, which is a temperature that pasteurizes the food waste material, eliminating all risks of disease and pathogens. It does that by using the naturally occurring bacteria, which we harness in these digestive vessels, and process the waste very efficiently under its own steam. So, there's no artificial heat used in this process, unlike a lot of other technologies, to comply with the regulations which we operate under. We made a conscious decision to locate inside the greater London area. London has a huge food waste problem. There is over a million tons per year. Most of the food waste isn't collected. It goes to landfill. What is collected is transported 60 miles out to Kent and Bedford for treatment. The road miles into our plant are typically eight miles. Waste is delivered into the site, tipped into the silo. The silo moves it to the shredder. The shredder grinds up into little bits. Metals and plastics are extracted. We end up with a thick porridge. These vessels are aerated. And we establish a colony of naturally occurring bacteria, which break down and digest the food waste. At the end of the process, it's stabilized and fully treated. We put it through a de-watering plant and turn it into a solid fertilizer that looks like compost. Our process here is carbon positive in operation. And that stands alone in all technologies that are currently deployed in the UK today. And we achieved that in the main from our end product. Our process in itself is very efficient and has a high throughput, occupies a small footprint and low land use. That's all good. An existing building is also carbon beneficial. But the key element of our carbon positivity is in our end product. Fertilizer that Vertal produces contains all the essential nutrients that are required to grow a commercial crop, be that wheat, be that barley, be that oilseed rape. Displacing the use of petrochemical and derived inputs, which are reliant on oil and gas for their production, and as a result are intensely carbon negative, has huge environmental benefits. Most of the food that is consumed in the world is produced because of the advances made in agriculture since the Second World War. We're now in the post-development phase, where the consequences of the success and the profligacy of the last 50 years are coming home to roost. The world is at a carbon crossroads. Major strategic decisions have got to be made right across the world. What we can do is to start to address the carbon imbalance. We're diverting waste from landfill, reducing carbon emissions in transport. And we're making fertilizer. Waste is a dirty business. People don't want to know, generally. Before recycling, it was all in landfill. It was all causing an environmental hazard. It was causing a smell. It was something that didn't want to be discussed. That's now starting to change. People are much more interested in what happens to the waste. Much more interested in the environmental impacts of waste treatment. And people are becoming more informed. And that's only a good thing. This is part of the sustainable loop. Our process completes the recycling circle. What you scrape off the plate is helping to grow your next meal, your next loaf of bread. It's as simple as that.

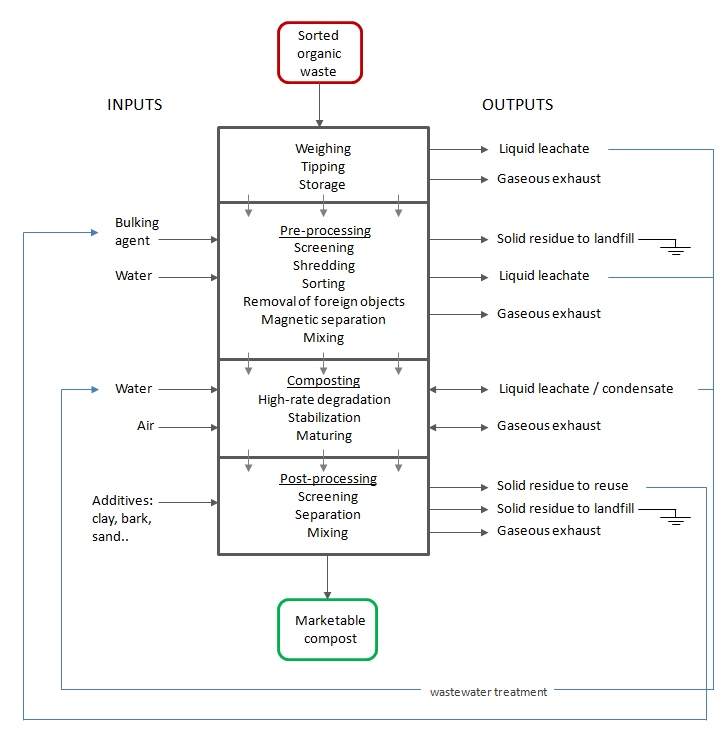

While having obvious benefits, composting is far from being environmentally clean. When organic components are mixed and concentrated during waste collection, they create aggressive gases and liquid effluents, which should be carefully controlled. In the diagram in Figure 5.3. The side inputs and outputs accompanying the composting process are shown. The pre-composting weighing and pre-processing stages generate liquid leachate, gas exhausts, and solid residue as by-products. The composting stage requires input of air and water, while generating more potentially polluting exhaust and effluents. Some of the residue is reusable, but some is not and need to be disposed of as non-recyclable waste.

Criteria that usually play a role in environmental and economic assessment of composting process are: energy use, transportation, land use, air quality. An example of multi-criteria analysis is presented in the “composting versus landfill case study, referenced below:

Reading Assignment:

Book Chapter: Solid Waste Technology & Management, Christensen, T., Ed., Wiley and Sons., 2011. (See E-Reserves via Canvas.)

Chapter 3.2. Christensen, T.H., LCA in Waste Management: Introduction of Principle and Method, Section 3.2.4.1. pp. 153-155.

Please study this example, and while reading try to get answers to the following questions:

- What are the pros and cons of composting compared to landfill?

- Which factors need to be taken into account to make composting a low-impact practice?

- What criteria / metrics did authors use in their assessment?

Supplemental Reading:

Book Chapter: Solid Waste Technology & Management, Christensen, T., Ed., Wiley and Sons., 2011

Chapter 9.2. Krogmann, U., Korner, I., Diaz, L., Introduction to Waste Management, pp. 533-565.

Interested in more technical details of composting technology? Refer to this reading material, which contains much of the technical information needed for specialists in this area.

This book is available online through PSU Library system.