Lesson 2.1: Life Cycle of Mines

Modern mining occurs over five stages, which constitute the life cycle of a mine. They are listed here and are summarized in the following paragraphs.

- Prospecting

- Exploration

- Development

- Exploitation

- Reclamation

While the principal activities of each stage are distinct, there can be significant overlap in the tasks comprising the stages as well as the professionals active in the stages.

Prospecting

The crust of the Earth is made of rocks and minerals, and many minerals can be found with little difficulty. In general, the challenge is not finding the mineral of interest; but rather finding an economic concentration of the mineral. Despite the fact that minerals are everywhere, it is a rarity to find most of them in sufficient concentration to justify the cost of developing a mine and extracting the mineral of interest. In most instances, prospecting is about finding geologic anomalies! The professionals that lead this first stage of the life cycle are geoscientists, e.g., geologists, geochemists, and geophysicists.

Geologists often narrow their search by taking advantage of accumulated knowledge, which may be public or proprietary, to narrow the geographic scope of their search. They may use satellite images or aerial mapping techniques as they search for promising indicators. Then the search will continue with on-the-ground investigation using surface-mapping, structural analysis, and other scientific techniques. In many cases, the expertise of geochemists and geophysicists may be required to help in the discovery of an orebody, i.e., a potentially economic concentration of the target mineral(s). Geochemists may glean vital clues by analyzing water or soil samples, for example; and geophysicists may use instruments to detect subtle and localized changes in the electrical or magnetic field, or they may map rock layers deep under the surface using seismic methods.

The goal of this team of geoscientists, and indeed the goal of prospecting, is to discover a concentration of the target mineral that has the potential to be mined at a profit. What do you think determines if it has the potential to be mined at a profit?

While there are many factors that will be considered, there are only a few that are germane at this stage. Those few would include the size and grade of the orebody. If the outcome of the prospecting stage is evidence supporting the presence of an orebody of sufficient size and grade to justify mining, then work will begin on the second stage, known as exploration. The prospecting stage may have cost tens of thousands to millions of dollars. The next stage may be even more expensive, and is only undertaken if there is sufficient evidence to suggest an economic deposit of the target mineral(s).

Exploration

The next stage, exploration, will involve mining engineers as well as geoscientists who were involved in the prospecting stage. The goal of exploration is to define more exactly the size of the orebody, the grade, and the spatial and geotechnical characteristics of the deposit and surrounding rock. I think it is useful to think about exploration as a problem in risk management.

What is the risk that we need to manage? Simply, the risk is that we would spend millions of dollars to develop a mine, only to find that we can’t mine the deposit economically. How could we find ourselves in such a job-ending predicament? Perhaps the size of the deposit is far less than we estimated, or the grade is much poorer than we believed, or maybe there are large areas where the ore disappears or where there are intrusions of unwanted material, or features that make it difficult to extract, and so on. You get the idea – you need to be a good risk manager!

If you are the one to make the decision, to go forward or abandon the project, what can you do to manage your risk? You can seek to obtain as much information as possible about the deposit, although information acquisition comes at a price. It costs money to conduct more studies to learn more about the deposit. How much are you willing to spend? How badly do you want that information? Well, that depends on how much risk you are willing to accept. Hence, the concept of, and need for, risk management. As we continue through this lesson and this course, you will begin to develop a sense for managing the risk associated with these projects.

Our first significant encounter with risk management is in the exploration stage, and our first interest will be to estimate the size of the reserve, i.e., how many tons exist than can be recovered, and the quality of the reserve, i.e., what percentage of the recoverable tons contain the target mineral(s). This first task is known as reserve estimation, and consists of two parts: estimating the quantity and quality of the orebody; and determining how much of that orebody can be recovered utilizing currently available mining practices. Estimating the quantity and quality of the resource requires sampling, usually by drilling, and then analyzing the sampled material. Generally, the more samples that we take, the more certain we can be in our estimates of the quantity and quality of the resource. In other words, the more we sample, the more we reduce the risk of bad outcome. And of course, it costs money to acquire each sample!

However, it is not only about the quantity and quality of the resource. We could have a resource of high quality and enormous size. But that alone is insufficient. We have to be able to extract this resource economically from the earth. This is not always doable, or more likely, it is doable for some but not all of the resource. The technical reasons for this are varied, but during the exploration phase, the team will be interested in far more than simply the size of the resource. They will employ methods to estimate the strength of the rock surrounding the orebody as well as the strength of the ore itself. They will look for geological discontinuities and other features that will affect the extraction of the ore. Investors in an expensive mining project are far more interested in how much ore can be mined, processed, and sold, than how much ore is in the ground! We’ll look at this in more detail in Module 3 when we talk about resource and reserve estimation.

There is one of two likely outcomes from the exploration stage: a decision to continue development on a project that appears promising or a decision to abandon the project. If the decision is to move forward with the project, then work will advance to the development stage.

Development

Essentially, the development stage includes all of the activities necessary to prepare for extraction of the ore. These activities begin with the engineering studies that immediately follow the exploration stage through the construction of the physical plant to access and process the ore. In the case of a surface mine, the development work to access the orebody may consist of removing vegetation and the overburden, which covers the orebody; whereas in the case of an underground mine, the development work will conclude with the construction of the shaft or other means of connecting the surface with the orebody that is located some distance beneath the surface.

A significant amount of capital must be available to open a mine. In many cases, this money must be raised from investors, and on some cases the company will have the capital to invest in the project. In either case, additional engineering studies will be conducted to establish the feasibility of opening a mine. A company with its own capital, will have many competing projects for that money, and they will want to allocate it to the project that best meets their criteria for a return on their capital. Investors on the other hand, will also want to understand the income potential of their investment. And in either scenario, both will want to understand the risks associated with the project. In Module 4 we will look at the engineering studies that are performed to address these concerns. For now, you should be aware that a prefeasibility study is nearly always conducted as the first task in this stage; and that the requirements for conducting and reporting on this prefeasibility study are prescribed by legal documents and are regulated by various government agencies around the globe. It is a requirement that these studies, completed according to the applicable standard, be published as part of an effort to raise funds for the project on any of the stock exchanges.

The selection of the mining method will be made during the prefeasibility study, as this is an essential consideration when determining how much of the in-place resource can be extracted. The selection is based on an evaluation of several factors that we will examine in Module 4; often the choice of a method will be guided by the practices found in other mines in the region that are mining some the same commodities.

The prefeasibility study will determine in most cases whether or not a viable project exists. If so, the development work will continue. Rights to the land and the deposit will be acquired, detailed engineering studies will be completed, bid packages will be prepared, and construction will begin on surface facilities, such as offices and labs, warehouses, shops, and the mineral processing plant, among others. Land clearing and other surface infrastructure construction, including roads, electric power, water, and so on will be ongoing during the development stage. As described previously, the development stage is largely completed with those tasks that allow direct access to the orebody. Once the orebody has been made accessible, the extraction process can begin.

Exploitation

One definition of this word, according to the dictionary, is the process of making the fullest and most profitable use of a natural resource. Indeed, the process of extracting the ore from the surrounding rock and processing it to make the valuable components available to society is the goal of the exploitation stage. Essentially, this stage consists of the extraction activities, in which we remove the ore and move it to a plant for the beneficiation activities, in which we separate and concentrate the valuable minerals from the run-of-mine materials coming from the mine and going into the mineral processing (beneficiation) plant. An important concern is the handling and disposal of these tailings, which remain after the valuable components have been removed. We will say little about the mineral processing other than these two points: the design and operation of mineral processing is beyond the scope of this course; and the mining engineer, in the selection and use of a particular mining method, along with the associated unit operations, can impact significantly the cost of the mineral processing operation. We will concern ourselves with the latter point, when we talk about the selection of the mining method and some of the unit operations.

The mining method will have been chosen well before exploitation begins, although the method may be altered or occasionally changed if conditions change significantly. Over time the equipment and practices may be changed to achieve economic, environmental, or safety goals. After all, many mines will be in the exploitation stage for several decades, and during this time the available mining technology and state-of-the-art practices will certainly change, even if mining conditions at the mine have not changed significantly from the day that the mine was opened. It is not unusual to find mines that began as surface mines, and then after the resource could no longer be recovered economically by surface mining, an underground mine was developed.

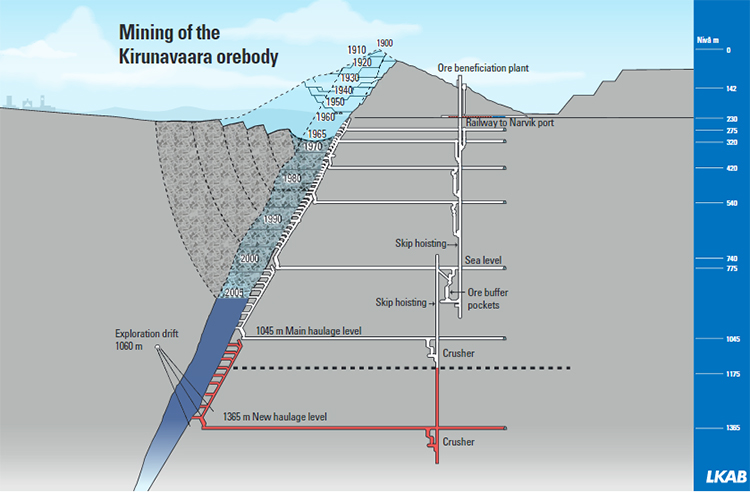

Mining of the Kirunavaara iron orebody in Kiruna, Sweden is a famous example of this, and as you will note in the Figure 2.1.1, below, that mining began in 1900 as a surface mining operation, and continued as such for 65 years. At that point in time, the cost of removing the overburden to access the ore became greater than the value of the ore that was being uncovered. This is known as the breakeven stripping ratio, and when this ultimate pit limit has been reached, mining will stop or alternatively, an underground mine will be developed; and that is what happened at this mine. Nearly 125 years after the initial mining, the mine still has many years of life remaining.

Whether it is in five, fifty, or five-hundred years, the exploitation stage will come to an end. The orebody for which the company has the rights to mine may have been exhausted, it may be uneconomical to continue mining, or the perhaps the market for the commodity no longer exists. Regardless of the cause, at the conclusion of active mining, the company cannot simply “walk away” from the operation; although well into the beginning of the 20th century that was the common practice. That irresponsible practice has left us with a legacy of abandoned mines, numbering in the thousands. Even though most of these were very small operations, some were large, and regardless of their size, many of them present public safety and environmental hazards. There may be, for example, shafts that hikers could unwittingly fall into, pollutants draining from old workings, or unsightly piles of tailings. This is a serious issue for society, and it is a major reason why mining has a negative public image.

The conclusion of active mining signals the beginning of the fifth and final stage in the mine’s life cycle, known as reclamation.

Reclamation

The goal of this final stage is to return the mine site to its original condition. In the case of an underground mine, we can do that rather completely. In the case of a surface mine, we cannot in many cases return it to original condition because so much material will have been removed and sold. However, we can take steps to ensure that the area is reclaimed to be free of safety and environmental hazards in all cases, and that the end result is aesthetically pleasing in many cases. The latter is simply impossible in the case of large open pit mines, as the volume of material removed over the years is so large that the remaining pit dimensions cannot be covered over. The number of these operations is a very small fraction of all surface mines, and the majority of these are located in rather remote and rugged areas. However, to be clear, even in those cases, the obligation to leave an area free of safety and environmental hazards is unchanged.

Overall, and during the reclamation stage, it will be necessary to remove completely all of the surface physical plant, e.g., buildings, power lines, and so on. Returning the land to original contours and/or ensuring that options for land use after mining are as good or better than the use prior to mining is important. This work may include grading and revegetation, among other steps. In most cases, the final outcome of the reclamation stage is a site on which the land is once again available for public or private use, free of hazards, and often more attractive and useful than prior to mining.

Of course, it is not just left to the social conscience of the company to ensure that reclamation is completed: there are laws, regulations, and multiple government agencies to ensure that the reclamation is completed. In fact, you will have to prepare and submit your plan for reclamation before you have started mining. And, in virtually all cases, you will have to put up a bond to ensure that the reclamation can be completed, even if you go out of business before the site has been fully reclaimed. These bonds are funded at a level to ensure that the work can be completed if the company defaults on its obligation. The cost of bonds can run into the millions of dollars very quickly, and the money is not returned to the company until the work covered by that bond is completed and approved by the government agency. In some cases, a company may need to operate a water treatment plant in perpetuity to ensure, for example, that groundwater drainage from an abandoned underground mine does not pollute the local streams. In such a case, the company will be required to post a bond of sufficient value that the government could continue to operate the plant if the company should go out of business.

Such planning and actions are consistent with the 21st century goal of sustainability. Whether we’re meeting humankind’s need for food or minerals, for example, we have a societal obligation to do so in a sustainable manner. This is generally accepted to mean that in meeting our current needs, we will use practices that will not compromise future generations’ ability to meet their needs. Further, it is implied that these practices will not compromise the environment nor the health of future generations. Sustainable practices are based on recognition that resources are finite. Consequently, we design mines to maximize the extraction ratio so that we can meet our production goals while disturbing as little of the resource as possible. In contrast, years ago, some mines might only recover less than half of the in-place reserve, but in the process, they would “sterilize” the remaining resource, i.e., the remaining resource could not be safely recovered in the future because of the way that the previous mining was conducted.

The five stages of a mine’s life cycle as presented in this lesson are a convenient way to describe the sequence of activities that define a modern mining operation. As you have no doubt realized, the boundary between each stage is not as crisp as this lesson might have implied. Not only is there overlap, but also at different times and in different places, parts of the cycle may repeat. For example, as the exploitation of a deep metal mine continues, new exploration activities will be initiated, but not from the surface. Instead, they will be conducted deep within the mine, where the geologists have a “front row seat” to observe and characterize the orebody in greater detail.

In the next lesson, we’ll look at the body of laws that apply to these stages of mining.