9.4 Design of Algae Farms

Site selection is an important area to investigate. The best areas to grow algae are areas with adequate sunlight year round, with tropical and subtropical climates. In the US, this includes the following states: Hawaii, California, Arizona, New Mexico, Texas, and Florida. This also means that the temperature will moderate year-round. There also has to be adequate land availability (for open-pond systems) and close proximity to CO2 (i.e., near a power plant or gasifier). To keep costs at a minimum, water and nutrients must be available at lower costs and manpower kept at reasonable rates.

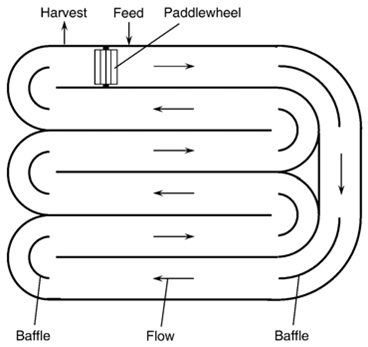

There are two main types of culturing technologies: open systems and closed systems. Open systems include tanks, circular ponds, and raceway ponds. Closed systems include three different types: flat-plate, tubular, and vertical-column enclosed systems. The figures below show several different examples of open and closed systems.

Open systems can be in natural waters or specifically engineered to grow algae. Natural water systems include algae growth in lakes, lagoons, and ponds, while the engineered systems are those described in the previous paragraph: tanks, circular ponds, and raceway ponds. Of course, there are going to be advantages and disadvantages of open systems. The main advantages are that open systems are simple in design, require low capital and operating costs, and are easy to construct and operate. However, disadvantages include little control of culture conditions, significant evaporative losses, poor light utilization, expensive harvesting, use of a large land area, limited species of algae, problems with contamination, and low mass transfer rates. One of the more common designs is the raceway pond. It has existed since the 1950s and is a closed-loop for recirculation channel for mass culture. The design includes a paddlewheel for mixing and recirculation, baffles to guide the flow at bends, and algal harvesting is done behind the paddlewheel. Cyanotech has a field of raceway ponds located in Kona, Hawaii, with a wide variety of algae.

So, what are some of the design features to keep in mind with algae systems? Algal systems are phototrophic, which means they need to obtain energy from sunlight to synthesize organic compounds. Therefore, the growth rate depends on light intensity, temperature, and substrate concentration, as well as pH and species type.

There are also factors that affect how specific systems are designed. Open pond design is affected by factors including the pond size, the mixing depth, the paddle wheel design, and the carbonator. The carbonator is how the carbon is added to the algae - it can be done in a number of ways, including carbonaceous seed materials, but utilizing CO2 from power systems (generated from the combustion of carbon-based materials) is one of the more common for algae growth - it also mitigates generation of GHG. We will not go into ways to design these systems, as that is above the level of this course.

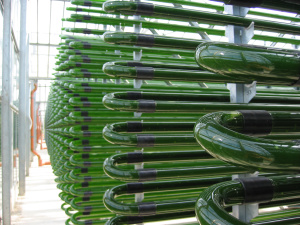

There are also a variety of closed systems. One type of system is the photobioreactor (PBR). Advantages of a system such as this include 1) compact design, 2) full control of environmental conditions, 3) minimal contamination, 4) high cell density, and 5) low evaporative losses. The disadvantages include: 1) high production costs, typically an order of magnitude higher than open ponds, 2) overheating, and 3) biofouling. A company that has systems such as this is Algatechnologies. They have a plant located in Kibbutz Ketura, Israel. The figure below shows a picture of the various algae they have growing in Israel.

There are three types of designs for the PBRs: flat plate, tubular, and vertical column. Advantages of the flat plate PBR include 1) large surface area, 2) good light path, 3) good biomass productivity, and low O2 build-up. However, the drawbacks include 1) difficulty in scaling up, 2) difficulty in controlling temperature, and 3) algae wall growth. A flat plate PBR is shown in the third figure. For the tubular PBR, advantages include 1) good biomass productivity, 2) good mass transfer, 3) good mixing and low shear stress, and 4) reduced photoinhibition and photooxidation. Tubular PBRs also have disadvantages: 1) gradients of pH, dissolved O2 and CO2 along the tubes, 2) O2 build-up, 3) algae wall growth, 4) requirement of large land area, and 5) a decrease in illumination surface area upon scale-up. The two previous figures are examples of tubular PBRs. Vertical column PBRs have different advantages and disadvantages. The positive features include 1) high mass transfer, 2) good mixing and low shear stress, 3) low-energy consumption, 4) high potential for scalability, 5) easy sterilization, and 6) reduced photoinhibition and photooxidation. The negative features are: 1) small illumination surface area, 2) need for sophisticated materials for construction, and 3) decrease in illumination surface area upon scale-up. The figure below shows a vertical column PBR.

We can compare open and closed systems by looking at various parameters and providing general comparisons of these systems. The table below provides a list of parameters to compare for each type of system. Open systems tend to cost less, but process control is difficult, and the growth rate is lower. Closed systems are a much higher cost, but control is much better and productivity is therefore higher.

| Parameters | Open systems | Closed systems |

|---|---|---|

| Contamination | High | Low |

| Process control | Difficult | Possible |

| Species control | Not possible | Possible |

| Mixing | Not uniform | Uniform |

| Foot-print | Extremely high | Very low |

| Area/volume ratio | Low (5 to 10 m-1) | High (20-200 m-1) |

| Capital cost | Low | High |

| Operation cost | Low | High |

| Water losses | Very high | Low |

| Light utilization | Low | High |

| Productivity | Low | High (3-5 times) |

| Biomass conc. | Low | High (3-5 times) |

| Mass transfer | Low | High |