8.2.3: Excavation Terms

These terms describe the types of openings that are created to facilitate mining of the deposit. The adjectives primary, secondary, and tertiary are used to characterize some of the terms. This is to indicate the relative importance of the opening in the same sense as saying interstate highways are primary roadways, two-lane streets in a city are secondary roadways, and the alleys between some streets are tertiary roadways. Some of these terms are specific to certain mining methods, and when we study those methods, they will become clearer. I want you to understand all of them, but for right now, focus on the ones that I have highlighted in red.

- Bell: Funnel-shaped excavation formed at the top of a raise to move bulk material by gravity from a stope to a drawpoint.

- Bleeder: Exhaust ventilation lateral.

- Chute: Opening from a drawpoint, utilizing gravity flow to direct bulk material from a bell or orepass to load a conveyance.

- Crosscut: Tertiary horizontal opening, often connecting drifts, entries, or rooms; oriented perpendicularly to the strike of a pitching deposit; also breakthrough.

- Drawpoint: Loading point beneath a stope, utilizing gravity to move bulk material downward and into a conveyance, by a chute or loading machine; also boxhole.

- Drift: Primary or secondary horizontal or near-horizontal opening; oriented parallel to the strike of a pitching deposit.

- Entry: Secondary horizontal or near-horizontal opening; usually driven in multiples.

- Finger raise: Vertical or near-vertical opening used to transfer bulk material from a stope to a drawpoint; often an interconnected set of raises.

- Grizzly: Coarse screening or scalping device that prevents oversized bulk material from entering a material transfer system; constructed of rails, bars, beams, etc.

- Haulageway: Horizontal opening used primarily for materials handling.

- Lateral: Secondary or tertiary horizontal opening, often parallel or at an angle to a haulageway, usually to provide ventilation or some auxiliary service.

- Level: System of horizontal openings connected to a shaft; constitutes an operating horizon of a mine.

- Loading pocket: Transfer point at a shaft where bulk material is loaded by bin, hopper, and chute into a skip.

- Manway: Compartment of a raise or a vertical or near-vertical opening intended for personnel travel between two levels.

- Orepass: Vertical or near-vertical opening through which bulk material flows by gravity.

- Portal: Opening or connection to the surface from an underground excavation.

- Raise: Secondary or tertiary vertical or near-vertical opening, driven upward from one level to another.

- Ramp: Secondary or tertiary inclined opening, driven to connect levels, usually in a downward direction, and used for haulage.

- Room: Horizontal exploitation opening, usually in a bedded deposit.

- Shaft: Primary vertical or near-vertical opening, connecting the surface with underground workings; also vertical shaft.

- Slope: Primary inclined opening, usually a shaft, connecting the surface with underground workings.

- Slot: Narrow vertical or inclined opening excavated in a deposit at the end of a stope to provide a bench face.

- Stope: Large exploitation opening, usually inclined or vertical, but may also be horizontal.

- Sublevel: Secondary or intermediate level between main levels or horizons, usually close to the exploitation area.

- Transfer point: Location in the materials-handling system, either haulage or hoisting, where bulk material is transferred between conveyances.

- Tunnel: Main horizontal or near-horizontal opening, with access to the surface at both ends.

- Undercut: Low horizontal opening excavated under a portion of a deposit, usually a stope, to induce breakage and caving of the deposit; also a narrow kerf cut in the face of a mineral deposit to facilitate breakage.

- Winze: Secondary or tertiary vertical or near-vertical opening, driven downward from one level to another.

If you haven’t done so already, this would be a good time to look at the figures.

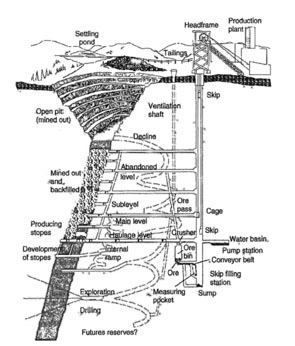

This figure from the text illustrates the basic infrastructure for a mine in a steeply pitching deposit. Generally, these mines are spatially complex.

The footwall and hanging walls are not labeled, but I am sure you can identify them after our previous discussion. The answer to the question of why the permanent structures such as the shaft are located in the footwall side of the deposit is: as areas are mined out within the deposit, it is likely that some caving will occur, and the caving can be a consequence or cause of fractures propagating through the hanging wall, and potentially ending at the surface. If there were any structures such as a shaft in the hanging wall of the deposit, they would be destroyed by the normal mining operation.

You’ll note the main levels versus the sublevels, and don’t miss the decline. Also, take note of the exploration-drilling program that is ongoing throughout the life of the mine.

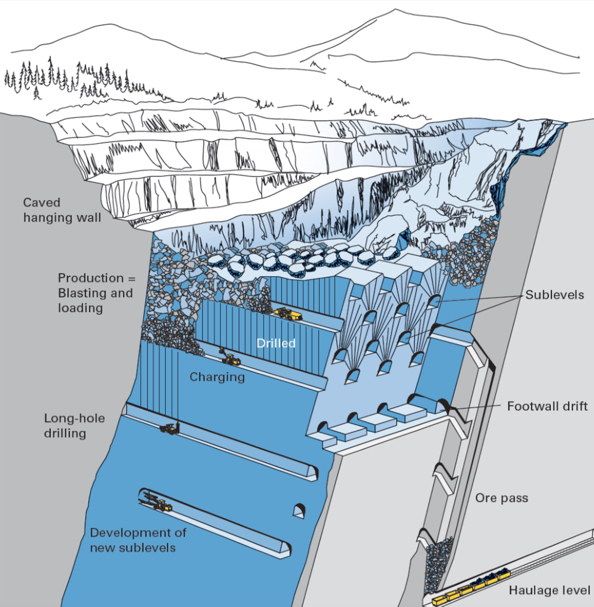

I like the next figure because it shows the footwall drift clearly as well as the sublevels and some of the unit operations within the sublevels. The ore passes down to the haulage level are easy to see in this figure, too.

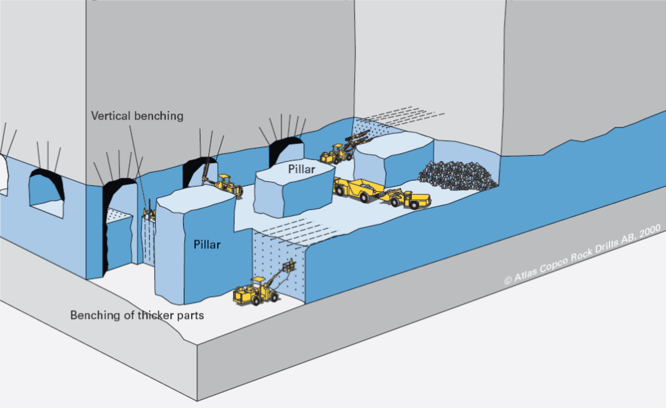

Finally, this third figure allows me to illustrate and elaborate on more of the terms. In thick-bedded deposits, it is often necessary to mine the bed in multiple steps known as lifts or benches. In this example, they are taking the seam in two lifts, and you can see the work underway on the benches. Specifically, you should be able to identify the locations where they are breast stoping, underhand stoping, and overhand stoping. You can also see the pillars that are being left behind to support the overlying strata.

Now that we have a common vocabulary to describe the elements of underground mines, as well as an understanding of these basic elements, we are ready to look at the underground mining methods. In the next two lessons, we will look at the methods. I think it is useful to put the methods into a context of their usage within the industry. That is to say, some methods are rarely applied, and others are frequently applied. Let’s finish up this lesson by taking a closer look at this.