7.2.3: Pit Terminology

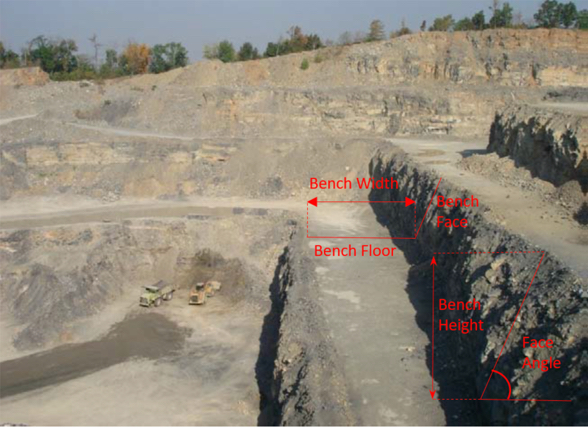

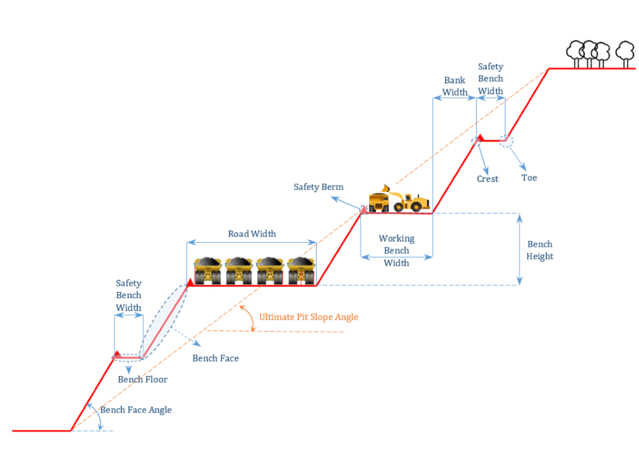

Now, let’s learn the terminology associated with the pits. Using this figure, we can define key elements.

- Bench floor: Horizontal surface of the bench

- Bench face: Vertical surface of the bench

- Face angle (α): The average angle the face makes with the horizontal

- Bench height (H): Vertical distance between upper and lower bench surface

- Toe: Interior vertex formed by the intersection of the bench face and bench floor

- Crest: Exterior vertex formed by the intersection of the bench floor and bench face

- Bench width: The distance between the crest and the toe measured along the upper surface

- Bank width: The horizontal projection of the bench face

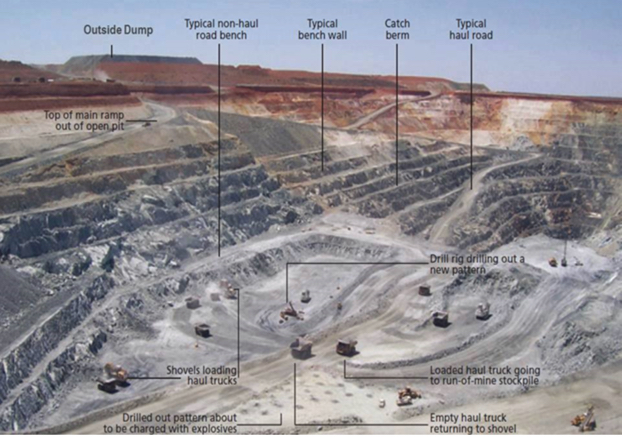

There are two types of benches in each open pit mine: working benches and safety (catch) benches.

Working Benches

Working benches are where unit operations (drilling, blasting, loading, and hauling) are performed. Working benches are wider than safety benches to provide enough room for the mining equipment to perform their tasks.

Safety (Catch) Benches

Safety benches are designed to collect the sliding material from the benches above and stop the downward progress of large rock pieces or boulders.

Bench height

Bench height is one of the first parameters to be determined during the mine design process. Can you guess the parameters that should be taken into account when determining proper bench height?

Bench height depends on several parameters:

Overburden and Ore Properties

We discussed before that ultimate pit slope depends on material (ore and waste) properties. These properties include rock strength and the number and direction of rock discontinuities. Benches are just like smaller pit walls with a much lower height (usually 20 to 50 feet). Therefore, benches should also be designed in such a way that no risk of instability is created due to excessive height of benches. There is a direct relationship between rock strength and safe values for the bench face angle and bench height.

Production Rate

Production rate of a mine is a parameter that is usually determined by market demand and selling capacity. When the required production rate is determined based on the market situation, then the annual mine production rate that includes ore and waste extraction is determined in such a way that enough product for the sale purposes is guaranteed. Higher benches are normally required to achieve higher production rates.

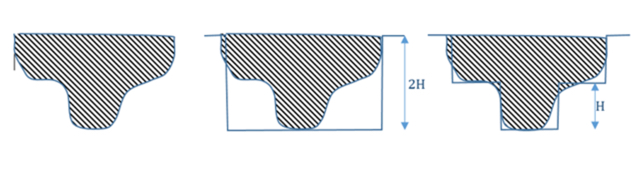

Degree of Selectivity

We discussed selectivity in the last lesson, and the definition of the parameter is unchanged. However, insofar as bench height is concerned, there is a selectivity issue, which is illustrated with these three figures, below. These figures (are attempting to) illustrate local variations in grade, and the effect of different bench sizes on the selectivity.

As you can see, the smaller bench height results in better selectivity. Better selectivity means less waste is mined, loaded, hauled, and run through the mineral processing plant; and this translates into lowered mining and processing costs. These mineral beneficiation plants are designed to work best when the characteristics of the feedstock into the plant lie within a specified range. If your feed into the plant is outside of the range, the plant’s efficiency will suffer. You may not recover all of the mineral, for example. Operating mines will use a blending strategy, where on a truck-by-truck basis, they will blend higher-grade and lower-grade ores to achieve a feed that is within the specified range. The more selectivity you have, the more effectively you can blend.

Size and Type of Equipment to Meet the Production Requirements

After the annual production rate of the mine is determined, the required daily and even hourly production rates will be calculated based on assumptions about the number of working days per year and the number of shifts per day. Then mining equipment is selected so that these production requirements can be met. Loading equipment is usually the first to be selected; next, appropriately sized trucks are chosen to match with the loader, and then the complete fleet of loading and hauling equipment will be specified. The maximum reach of the loading equipment should be roughly the same as the bench height.

Regulatory Limits

Federal and state regulatory agencies have regulations that limit bench height for specific mining operations, depending on the commodity, to ensure the safety of mine workers and equipment inside the pit. The engineering calculations may indicate that a greater bench height is safe, but it is unlikely that the regulatory agency would allow an exception to their rule.

Bench Face Angle

Bench face angle is ultimately limited by geotechnical considerations, as we generally want to have as steep of an angle as we can sustain without an unacceptable risk of a slope failure. Despite excellent engineering and slope monitoring, failures can occur. This photo was taken in 2013 shortly after the slope failure at the Bingham Canyon Mine. Look at the shops and warehouses in the picture to appreciate the size of this failure. It is truly a miracle that no one was killed – the potential was there for massive loss of equipment and multiple fatalities.

Please watch the following video (20:11). It will give you a good overview of the open pit mining method, as well as a bit more background on the slope failure. The first half of the video presents an interesting historical perspective, and the last half shows contemporary mining practices.

Safety Berm

A safety berm is a pile of broken material constructed along the crest to form a “guard rail” to prevent trucks or other equipment from inadvertently driving over the edge of the haul road. It also serves to catch falling rocks. The height of the safety berm should be greater than or equal to the tire radius of the largest truck. These berms are required by federal regulation, but even with berms, accidents can happen. The picture on the left shows a haul truck, or what remains of it, after going over the highwall; and the one on the right shows a piece of rock that slid off the highwall and landed on a truck below. The former most certainly resulted in a fatality, whereas the latter probably did not, in this instance.

Haul Roads

These are added to the pit walls to provide access between benches and the plant next to the pit. Open pit haul roads have a gradient up to 15%. The width of the haul road is designed based on the width of the largest truck that travels in the pit and the number of the lanes that are required to provide proper access for haul trucks, auxiliary equipment such as explosives trucks and water trucks, and smaller vehicles, such as pickup trucks, while minimizing congestion.

Now, let’s review the bench geometry concepts and open pit elements by looking at two annotated photographs.