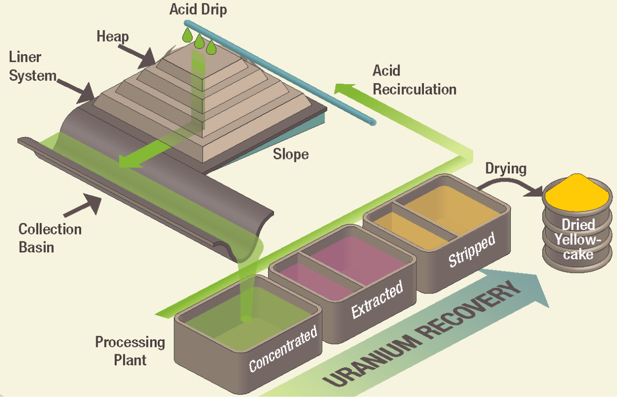

7.4.5: Heap Leaching Method

Heap leaching was first used to extract very low grades of metal ore from piles of plant tailings or waste rock. In the case of copper, for example, a solution of sulfuric acid was released at the top of the pile and allowed to percolate down through the pile. The effluent was collected and washed over scrap tin. The copper would precipitate out on the tin, the tin would then be smelted, and the copper would be separated from the tin. All-in-all, it was a fairly clever and economic process to extract metal from material that otherwise would have been discarded as waste. Unfortunately, there was no thought given to the consequences of the effluent seeping into the ground, and in the end, this practice resulted in massive pollution around the mine site. The old Anaconda Copper Company mine in Butte, Montana, for example became an EPA Superfund Site! Today, heap leaching is practiced, but with proper engineering controls in place to ensure that it proceeds with no damage to the environment. Among other precautions, extensive containment barriers are constructed with multiple levels of redundancy.

Today low-grade ores are “mined” on the surface and placed on these containment pads so that the valuable metal can be leached out of these “heaps.” This is an important method for recovering gold from low-grade ore that could not be economically processed by any other means. The mining of the low-grade ore is usually by large dozers, front loaders, and trucks. Usually, the depth of the excavation is quite limited, and two of the reasons for this are that as the deposit depth increases, the grade may improve to allow economic exploitation by another mining method; and the cost of excavating this low-grade ore increases with the depth, and quickly it becomes uneconomic. The time required for the leaching to be completed can vary from weeks to years, with the latter being more common; and during this period, bacterial action, as from metal oxidizing bacteria for example, is critical to the success of the process. A variation of heap leaching involves constructing the “heap” in a dump, and calling it dump leaching. Large containment vessels are being used on a limited basis as well.

Both heap leaching and borehole mining have become the favored exploitation methods for recovering uranium. This figure illustrates a heap leaching operation.

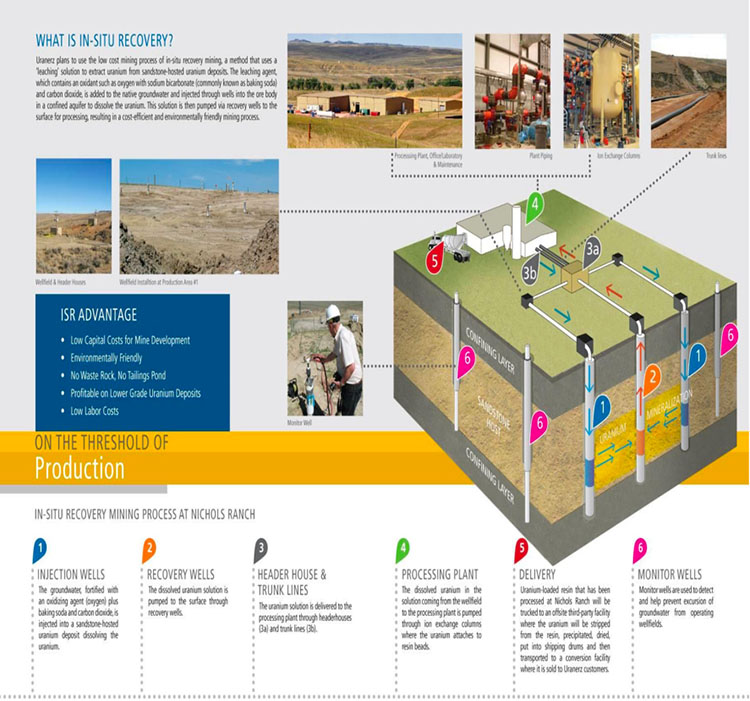

This figure illustrates the process at Uranerz’s Nichols Ranch Mine. This is a good example of how a borehole mining method is employed for in-situ recovery of a mineral.