The petroleum and natural gas engineering profession is normally divided into three major areas of specialization based on the tasks assigned to the engineer. These areas are: Drilling or Drilling and Completions (D&C) Engineers, Production Engineers, and Reservoir Engineers.

Drilling Engineers, or Drilling and Completions Engineers

Drilling Engineers, or Drilling and Completions Engineers, are responsible for planning, designing, and executing the drilling operations of a well. Drilling a well may take several years to properly plan. This is because of the depths and quality of the steel tubulars (drill pipe, casing, and production tubing) that are required by the oil and gas industry. For example, a ten-well drilling campaign to a total depth of 12,000 ft per well in a high temperature, high pressure, highly corrosive environment will take several miles of high-grade steel tubulars which cannot be purchased “off-the-shelf” from steel manufactures. These items are “Long Lead Time” items in the well design and must be considered years in advance of the actual drilling operations. In fact, an aggressive drilling campaign in a single oilfield may exhaust the world’s supply of a particular steel grade for several years. Coordinating the design of the well with the suppliers of the well components is an integral part of the planning process performed by the drilling engineer.

During drilling operations, the drilling engineer must also determine the appropriate drilling fluids to use to allow for safe drilling operations and select the appropriate drill bits to use to allow for optimal drilling efficiency (cost, speed, etc.). The drilling engineer must also decide on the appropriate depths to set casing and the appropriate steel grades of the casing to protect both the wellbore and the environment (Casing is used to isolate the well from the various geologic rock formations and aquifers that a well encounters and to isolate the individual rock formations from each other.).

Once the wellbore has reached the predetermined total depth and the final casing string has been cemented in place, the drilling engineer works with the production engineer to implement the well’s completion. The well completion is the portion of the well that connects the wellbore to the reservoir. This aspect of the well design has many considerations in order to achieve the long-term objectives of the well. Important considerations of a completion design include: selecting the appropriate size and grade of the production tubing; determining the need to stimulate the reservoir (hydraulic fracturing, acidizing, etc.) to allow for economical production rates from the reservoir to the well, and selecting the appropriate artificial lift system (natural lift, pump, gas lift, etc.) to aid in “lifting” the produced fluids from the reservoir to the surface.

Production Engineer

The role of the Production Engineer is to monitor individual wells or groups of wells to ensure that they are producing (or, in the case of injection wells, injecting) optimally. Over time, downhole equipment may fail, produced hydrocarbons fluids may deposit waxes or asphaltenes on downhole equipment and tubing, minerals in produced water may create a scale on downhole equipment and tubing, steel tubing may corrode or erode, etc. All of these phenomena can negatively affect the performance of the well. In addition, due to changing reservoir conditions, equipment and tubing sizes that were optimal at the beginning of production may be suboptimal at depleted reservoir conditions.

To monitor wells, production engineers may install permanent downhole sensing equipment to continuously observe well performance in real time. In addition, the production engineer may perform discrete tests on the well by sending monitoring tools down the well to observe well performance as a “snapshot in time.” These discrete tests can either be (1) well logs, where tools are sent downhole that measure properties of interest to the engineer such as flow rates, temperatures, internal tubing diameters etc., or (2) well tests, where pressure gauges are sent downhole, well rates are adjusted in a controlled, known manner, and the corresponding pressure responses are recorded and analyzed. The analysis of the pressure responses during a well test provides a valuable insight into the near-well performance of the reservoir.

If a problem is identified with the well, it is then up to the production engineer to determine the appropriate remedial actions to resolve the issue. These well remediations may take the form of simple “wireline workovers” or more complex “major rig workovers (MRWO).” In a wireline workover, all work is performed with tools lowered into the well at the end of an electrical cable (wireline). Using a wireline, perforations (connections to the reservoir) can be added, tubing plugs can be set or retrieved, packers (downhole equipment used to isolate reservoir zones) can be set or retrieved, valves can be opened or closed, etc. In a major rig workover, a drilling rig or specialized workover rig is moved on location above the well and is used to re-enter the well to retrieve the original tubing or completion equipment, cement off depleted reservoir zones (to establish zonal isolation), or to restimulate the well.

In addition to monitoring wells and performing well remediations, production engineers look after the artificial lift systems used in the well. Typical artificial lift systems include beam pumps (see Figure 1.05), downhole electrical submersible pumps (ESPs), or gas lift.

By the nature of their jobs, production engineers interact with oilfield service providers to ensure that the appropriate technologies are applied to optimize well production or injection.

Reservoir Engineers

While production engineers focus on individual wells or groups of wells, Reservoir Engineers attempt to optimize production of the reservoir as a whole. Reservoir engineers work with geologists, drilling engineers, and production engineers to ensure that the entire reservoir system is running optimally. Typical tasks performed by reservoir engineers include: working with geologists to determine the original-oil-in-place in the reservoir and identifying future well locations; identifying the drive mechanisms (the physical phenomena which cause the oil and gas to migrate to the production wells); estimating the reservoir reserves (volumes of oil and gas that can be technically and economically extracted from the reservoir), recommending the appropriate development plans for a reservoir (and recognizing when it is time to modify a plan); forecasting future production and injection rates from the reservoir in its entirety; and determining the need for applying Improved Oil Recovery (IOR) or Enhanced Oil Recovery (EOR) methods.

Typically, petroleum engineering students have the option to choose which of these areas of specialization they would like to undertake during their careers; however, the Law of Supply and Demand also works in the petroleum and natural gas engineering job market. For example, a company in need of the services of Production Engineers will hire engineers with this particular skill set. Consequently, some degree of flexibility among these three areas of specialization is required when searching for an entry-level position in the oil and gas industry.

The modern approach to crude oil and natural gas extraction is the Reservoir Management approach. Reservoir Management is a team based methodology in which all disciplines (geologists, drilling engineers, production engineers, reservoir engineers, and other petroleum professionals) work together toward the common goal of efficient, safe, and environmentally friendly production of oil and gas.

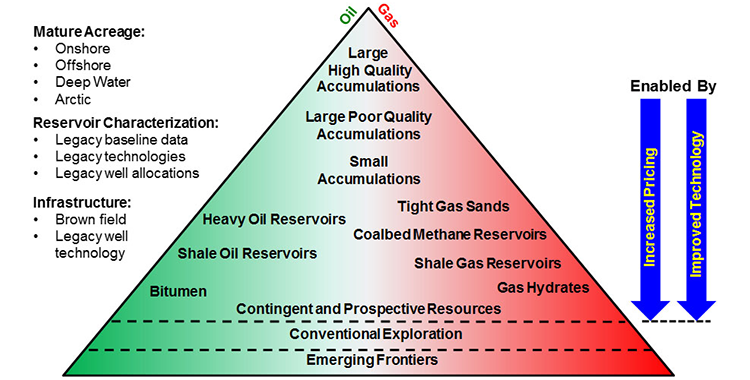

Current status and future challenges of Reservoir Management can be summarized with the Resource Triangle [1]. Figure 1.06 shows the current status of Reservoir Management in the Resource Triangle. In this figure, the easy-to-produce resources (crude oil and natural gas) are at the top of the triangle. These resources are characterized by good, high-quality reservoir rock (high storage capacity and ability to easily transmit fluids) which are saturated with highly mobile (easily flowing) fluids. The base of the triangle represents the more difficult-to-produce or yet to be discovered resources. While the resources at the base of the triangle are more difficult to find and extract, they can still be produced at higher energy prices (allowing for more capital to be spent to find, drill, and apply cutting-edge technologies for their extraction) or with improvements in current technology.

Figure 1.06 also illustrates the status of producing assets in known, mature basins. Due to the time-scales of oil and gas production, we are still producing from fields that were discovered in the early to mid-twentieth century. Consequently, some of the equipment installed in the field may be legacy equipment (then-current technologies) and all of the pre-production, baseline data for these fields were acquired using legacy data acquisition technologies. This is the situation in which many newly graduated petroleum and natural gas engineers may find themselves. Consequently, these engineers must be well versed in past, present, and emerging production technologies and analysis techniques.

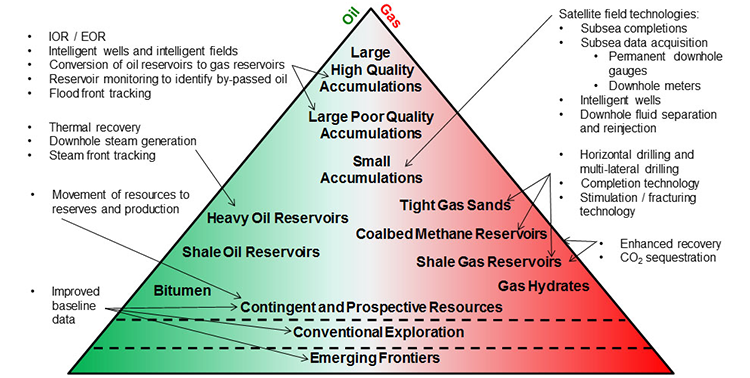

The Resource Triangle can also be used to illustrate the future challenges in Reservoir Management, as in Figure 1.07.

Figure 1.07 shows the same “easy-to-produce” and “difficult-to-produce” resources as in Figure 1.06. All of these resources, including the “easy-to-produce” resources, have various challenges associated with them. It is the role of petroleum and natural gas engineers to devise cost-effective solutions to these challenges.

Typically, even in the best quality reservoirs, only one-third of the original-oil-in-place can be recovered using conventional production technologies (typically 30 – 35 percent recovery efficiencies). Recovery efficiencies for natural gas reservoirs are normally much greater (typically 65 – 85 percent recovery efficiencies). The remaining in-place oil and gas after the application of conventional production technologies, therefore, represents a significant target for additional recovery.

[1] Reference: MRS Bulletin: Factors That Will Influence Oil and Gas Supply and Demand in the 21st Century