Improved Oil Recovery (IOR) and Enhanced Oil Recovery (EOR) Methods are methods used to target the resources not capable of being produced with conventional production methods. IOR is defined as any recovery method used to improve oil recovery above the use of non-stimulated, naturally-flowing vertical production wells (Please note that with this definition, each reservoir will have a different baseline because each reservoir will respond differently to the application of these wells). This baseline represents the simplest production technology available to the petroleum and natural gas engineer and was a common development option up to the 1960s – 1970s and often resulted in recovery efficiencies of less than ten percent.

This definition of IOR encompasses a wide variety of production technologies including additional vertical wells (infill drilling) or complex well designs (deviated, or slanted, wells; horizontal, or single-lateral, wells; multi-lateral wells), well stimulation (hydraulic fracturing and acidizing), artificial lift (beam pumps, ESPs, and gas lift), secondary recovery methods (waterflooding and gas flooding), and EOR (thermal recovery, miscible displacement, and chemical flooding).

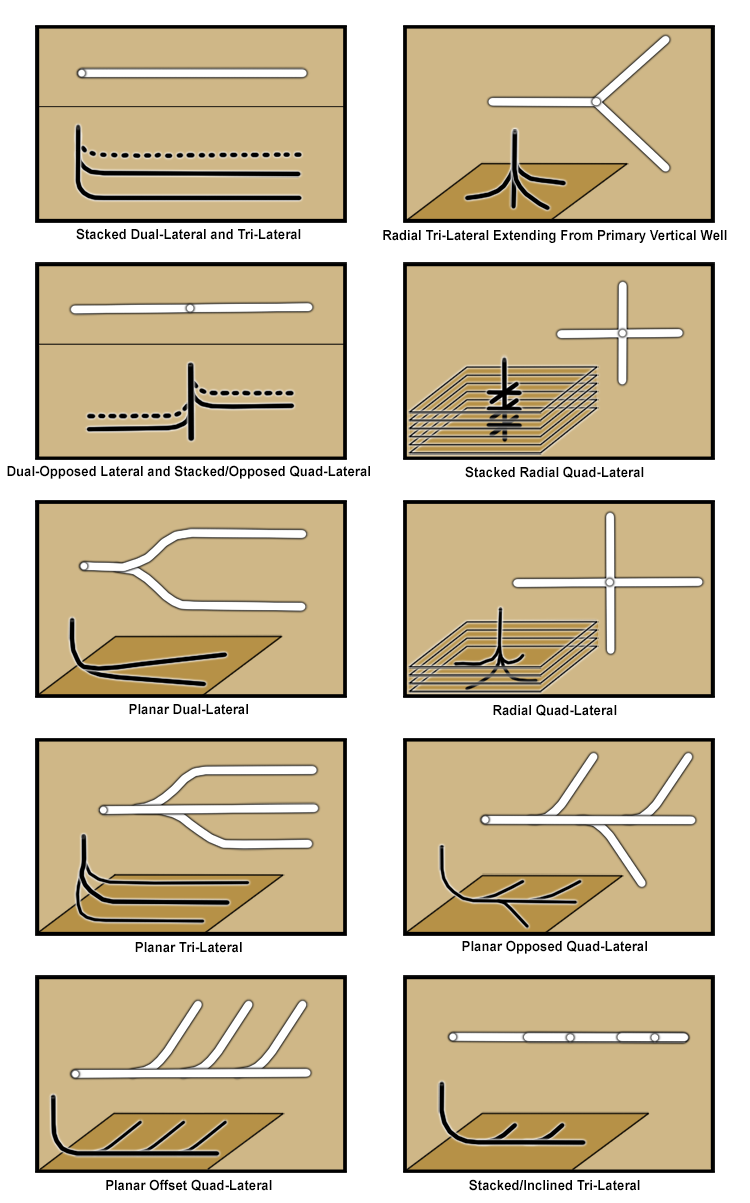

This definition of IOR allows for the use of additional vertical wells for greater well coverage (infill drilling) than considered in the initial development plan or the use of more complex well designs to improve well performance from a single surface location. Figure 1.08 shows some of the more advanced well designs used in the current Reservoir Management. As discussed earlier, the design and execution of these complex wells is the task of the drilling engineer.

Well Stimulation

Well stimulation is an IOR technology that is used to clean well perforations and improve the flow capacity of the reservoir rock in the near-well vicinity. The two most common well stimulation methods are hydraulic fracturing and acidizing. Hydraulic fracturing, or frac’ing, refers to the high-pressure injection of a fracturing fluid, typically water (slickwater), gas, or gel, into a reservoir causing the rock to mechanically fail or fracture. Injection of the fracturing fluid is normally followed by the injection of a proppant slurry, composed of natural sand or man-made ceramic beads, used to prop-open the induced fractures once pressure is relieved after the well stimulation treatment. Hydraulic fracturing can be applied to most rock lithologies, including sandstones, carbonates (limestones and dolomites), coals, and shales.

Acidizing

Acidizing is a well technology that uses the injection of an acid solution into a porous reservoir to dissolve any residual drilling fluids or natural sediments in the well perforations and the near-well vicinity. These residual drilling fluids may impair fluid flow to the well. Several variations of the acidizing process are used to stimulate a well including: matrix acidizing where the acid solution is pumped into the reservoir below the fracture pressure (or parting pressure) to clean pores near the well and acid-fracturing where an acidic fracturing fluid is injected above the fracture pressure in order to simultaneously fracture the reservoir and dissolve the formation (creating flow channels linking the rock to the fracture). Matrix acidizing is typically used in sandstone and carbonate reservoirs; while acid-fracturing is used in carbonate reservoirs which are susceptible to breakdown by acid.

Artificial Lift

Artificial lift was discussed briefly and is defined as an IOR technology used to ”lift” reservoir fluids once they enter the well. Early in the life of a well, the natural pressure in the reservoir is great enough to overcome gravity and to push fluids to the well and up the well to the surface. This is referred to as natural flow or natural lift.

As pressure is depleted from the reservoir by the withdrawal of oil, gas, and water (comparable to letting the air out of a balloon), the natural energy in the reservoir can no longer overcome the weight of the produced fluids and cannot force them up the production tubing. At this point, the application of artificial lift is required to keep the well flowing. A second situation may also occur which requires the application of artificial lift. As oil and gas are produced from the reservoir, these fluids are often replaced by increasingly greater volumes of produced water. The produced water is a much heavier fluid than the oil and gas and the fluid column in the well may become too heavy to flow by natural means. When this occurs, artificial lift is required to continue to produce the well. As discussed earlier, the tasks of well stimulation and artificial lift fall to production engineers.

Secondary Recovery

Secondary Recovery is an IOR process used for increasing the recovery efficiency of many oilfields. In this context, Primary Recovery refers to Reservoir Management processes which deplete the reservoir energy from the natural drive mechanisms associated with the reservoir. In secondary recovery, water or natural gas are injected into the reserve to provide an external source of reservoir energy. Waterflooding is the most common form of secondary recovery used for crude oil production.

The terms, Primary Recovery and Secondary Recovery, refer to the historical order in which oil production techniques were applied. Primary recovery was typically applied as a first stage of development to take advantage of the natural drive mechanisms in the reservoir; while secondary recovery was applied at a later stage of development to supplement the depleted natural drive mechanisms. Reservoir Engineers typically determine the design and timing of the secondary recovery operations. Most oil reservoirs require some form of secondary recovery to achieve recovery efficiencies in the range of 30 – 35 percent.

Enhanced Oil Recovery, or Tertiary Recovery

In Figure 1.07, Enhanced Oil Recovery (EOR), or Tertiary Recovery, is also applied to large reservoirs. EOR involves the injection of fluids into the reservoir, which aids in crude oil production by means other than simply supplying external reservoir energy. The baseline for EOR is the incremental production after primary and secondary production. Note that this definition of the baseline for EOR differs from that for IOR. As the terminology implies, “Tertiary Recovery” technologies were historically used after primary and secondary recovery.

The type of EOR technology to be applied to a given reservoir depends on the nature of the reservoir and the fluids that it contains: polymer solutions can be used to improve the efficiency of a waterflood; miscible fluids or surface active agents (surfactants, or soup solutions) can be injected to reduce capillary forces (one of the forces that entrap crude oil in the capillaries in the reservoir); or steam can be injected into heavy oil reservoirs to reduce the viscous forces (another force that entraps crude oil) required to displace the oil. Again, the design and timing of an EOR project typically fall to the reservoir engineer.

Figure 1.07 also illustrates a current trend in Reservoir Management: the use of “Smart Technologies.” Smart technologies are capable of sensing changing reservoir conditions and modifying production characteristics in real time to continuously improve reservoir performance.

The very base of the Resource Triangle, “Emerging Frontiers,” may sound somewhat exotic; however, the last “emerging frontier” in the oil and gas industry occurred in western Pennsylvania. This was the Shale Boom that began in the mid-2000s.

It was the application of hydraulic fracturing, in conjunction with the application of the more complex, multi-lateral well designs, which made shale reservoirs commercially viable. One such shale formation, the Marcelus shale, is a massive oil and gas bearing formation located in western Pennsylvania, Ohio, West Virginia, and New York. Oil and gas production from the Marcellus shale, along with the Barnett shale (Texas), Bakken shale (North Dakota), and the Eagle Ford shale (Texas) have significantly reduced the dependency of the United States on foreign energy sources during the last decade and is projected to continue to produce for decades to come. As with all aspects of energy production, the longevity of the shale boom will depend on future oil and gas prices.