Pipeline Safety

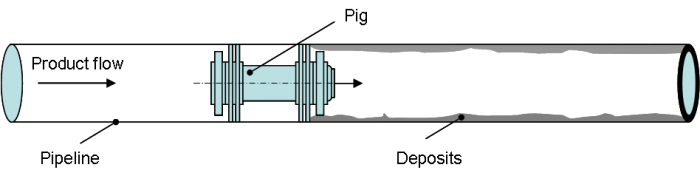

To ensure the efficient and safe operation of natural gas pipelines, pipeline operators routinely inspect their pipelines for corrosion and defects. This is done through the use of equipment known as pigs. Pigs are robotic devices that are propelled down pipelines to evaluate the interior of the pipe. Pigs can test pipe thickness and roundness, check for signs of corrosion, and detect leaks and other defects along the interior of the pipeline that may either impede the flow of gas or pose a safety risk for the operation of the pipeline. Sending a pig down a pipeline is fittingly known as “pigging” the pipeline.

In addition to inspection with pigs, a number of safety precautions and procedures are in place to minimize the risk of accidents. A few of the safety precautions associated with natural gas pipelines include:

- Aerial patrols: Planes are used to ensure that no construction activities are taking place too close to the route of the pipeline, particularly in residential areas. Unauthorized construction and digging is the primary threat to pipeline safety in many areas.

- Leak detection: Natural gas detecting equipment is periodically used by pipeline personnel on the surface to check for leaks. This is especially important in areas where the natural gas is not odorized.

- Gas sampling: Routine sampling of the natural gas in pipelines ensures its quality and may also indicate corrosion of the interior of the pipeline or the influx of contaminants.

- Preventive maintenance: This involves the testing of valves and the removal of surface impediments to pipeline inspection.

- Emergency response: Most pipeline companies have emergency response teams that train for the possibility of a wide range of potential accidents and emergencies.