Well Pad Development

Once an energy company has taken care of the exploration work, leased the land they are interested in drilling on, selected the initial drilling sites and has applied for and received their drilling permits they can begin to prepare a site for the drilling process, referred to as the well pad. The site preparation work itself may take several months and cost several hundred thousand dollars to construct pending on how much earth-moving work needs to be completed for the well pad. The area needed for a well pad which typically ranges from 5-10 acres in size, depending on how many wells may ultimately be drilled on it, which may be just one or more than twenty. Where the topography is more sloped it will likely take more excavation work in order to grade out the well pad, which needs to be flat and stable to accommodate the drilling rig and fracturing equipment. The design of the well pad needs to be consistent with state regulations as described in the previous section, and be engineered to handle stormwater, contain spills while maintaining slope stability. In addition, environmental factors such as the presence of wetlands, proximity to surface water, and sensitive wildlife habitat need to factored into the site selection and construction process to minimize any impacts.

This video describes the well pad and the reason for their size.

Video: Well Pad Size (00:38)

The size of the well pad behind me is typically about four to five acres. That's large enough to bring in the drilling rig and the associated equipment. And then once the wells are drilled, the drilling rig moves on to the next well pad, and the hydraulic fracturing equipment is brought in. So you need about that much space to actually accommodate all of that equipment. Once the wells are fractured and brought online, and are producing gas, then about half of the well pad can be reclaimed.

The series of pictures below show the stages of building a well pad, from tree clearing, earth moving, and final construction ready for drilling.

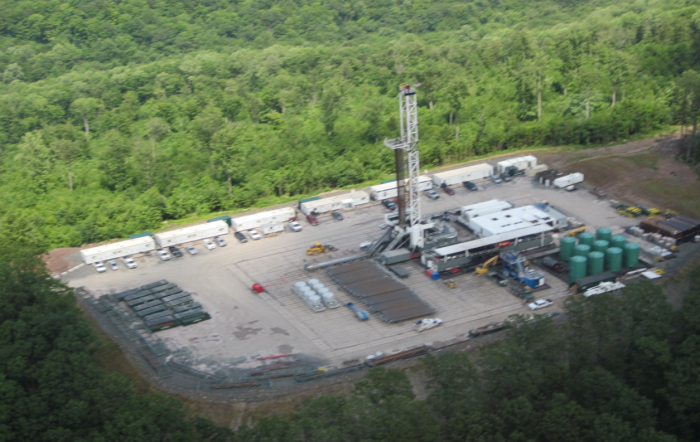

Once the well pad is constructed, the drilling rig can be brought in to begin to install a well or multiple wells off of the same well pad. The picture below shows a well pad with an active drilling rig. Notice that the drilling rig is on a well pad surrounded by forest, therefore there's no power or other infrastructure at the site. This means the drilling company must bring in their own power generators, compressors, and other equipment they need to run the rig and supporting operations, as shown below.

During the drilling and hydraulic fracturing stages, there are numerous drilling and fracturing fluid additives stored on the well pad that should not be released into the environment. Spill prevention precautions are always taken but in the case of an accidental release of chemicals, drill sites are protected by an impermeable liner with bermed edges to prevent contaminants from penetrating into the ground or running offsite as shown below. Even minor spills must be reported to the Pennsylvania Department of Environmental Protection (DEP) to ensure they are properly cleaned up.

Drilling or production fluids flowing from the subsurface during operations are stored temporarily in tanks on the pad until they can be reused or properly disposed of offsite and have secondary containment as shown in the photo below.

Now that the well pad has been constructed with the proper engineering and spill control measures in place the drilling rig can be brought on site, as summarized in the next module.