4.3h Summary

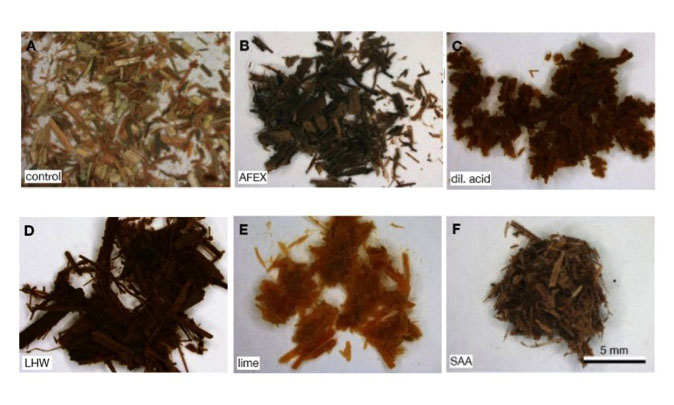

Of the methods we’ve discussed, there are pretreatment options that lead the others (some under commercialization). The current leading pretreatment options include dilute acid, AFEX, liquid hot water, lime, and aqueous ammonia, with dilute acid and water, AFEX, and lime under commercialization. The figure below shows switchgrass before pretreatment and after several pretreatment options, i.e., AFEX, dilute acid, liquid hot water, lime, and soaking in aqueous ammonia (SAA).

Control: mix of yellows and brown sticks

AFEX: dull brown sticks

Dil. Acid: red-brown clumps

LHW: dark brown red sticks

Lime: yellow-brown clumps and sticks

SAA: light brown sticks

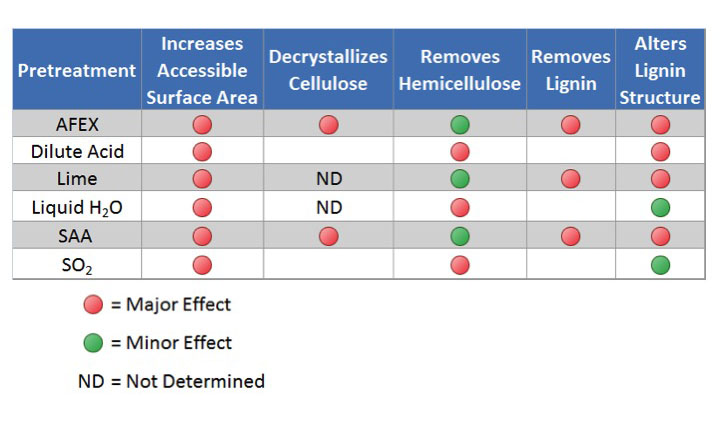

To summarize the methods of pretreatment, the table below shows some of these pretreatment methods and the major and minor effects on lignocellulosic biomass. All methods (AFEX, dilute acid, lime, liquid hot water, soaking aqueous ammonia, and treatment with SO2) have an effect on increasing surface area, removing hemicellulose, and altering lignin structure. Only AFEX, lime, and SAA pretreatment remove lignin, and AFEX and SAA decrystallize cellulose.

| Pretreatment | Increases Accessible Surface Area | Decrystallizes Cellulose | Removes Hemicellulose | Removes Lignin | Alters Lignin Structure |

|---|---|---|---|---|---|

| AFEX | Major Effect | Major Effect | Minor Effect | Major Effect | Major Effect |

| Dilute Acid | Major Effect | Major Effect | Major Effect | ||

| Lime | Major Effect | Not Determined | Minor Effect | Major Effect | Major Effect |

| Liquid H2O | Major Effect | Not Determined | Major Effect | Minor Effect | |

| SAA | Major Effect | Major Effect | Minor Effect | Major Effect | Major Effect |

| SO2 | Major Effect | Major Effect | Minor Effect |

This table shows the conditions for ideal pretreatment of lignocellulosic biomass for dilute acid, steam explosion, AFEX, and liquid hot water.

| Pretreatment Process | Dilute Acid | Steam Explosion | AFEX | Liquid Hot Water |

|---|---|---|---|---|

| Reactive Fiber | Yes | Yes | Yes | Yes |

| Particle Size Reduction Required | Yes | No | Nob | No |

| Hydrolyzate Inhibitory | Yes | Yes | No | Slightly |

| Pentose Recovery | Moderate | Low | High | High |

| Low-Cost Materials of Construction | No | Yes | Yes | Yes |

| Production of Process Residues | Yes | No | No | No |

| Potential for Process Simplicity | Moderate | High | Moderate | High |

| Effectiveness at Low Moisture Contents | Moderate | High | Very High |

Not Known |

a Modified from (86); AFEX ratings from Bruce Dale (personal communication).

b For grasses, data for wood not available.

Credit: Lynd, 1996. Annual Rev. Energy Environ., 21: 403-465