8.4.2b Sublevel Caving

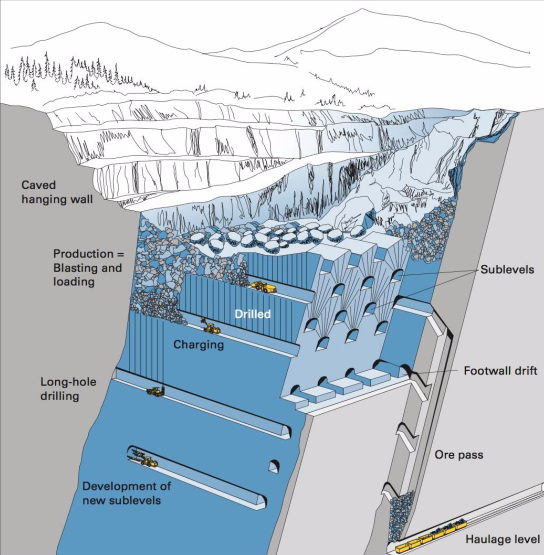

Sublevel caving shares many similarities with block caving, with one notable exception, which is responsible for this method: the orebody is competent and will not cave under its own weight. The host rock, on the other hand, is weak and caves behind the ore as it is extracted. Consequently, the orebody needs to be drilled and shot to extract the ore. Once extracted, the hanging wall caves. Given the similarities, we don’t need to say much, and especially if you look at this diagram of a sublevel caving operation, below. There are a few points to be made, however.

You will notice there is no need to develop and undercut, nor bells and drawpoints. Instead, a series of sublevels is developed, and next, the ore above the sublevel is fan or ring drilled. The holes are charged and fired. The broken ore is then loaded out of the sublevel using an LHD (or rarely, a slusher). The LHD’s travel to ore passes where the ore is dumped and then collected at a lower haulage level.

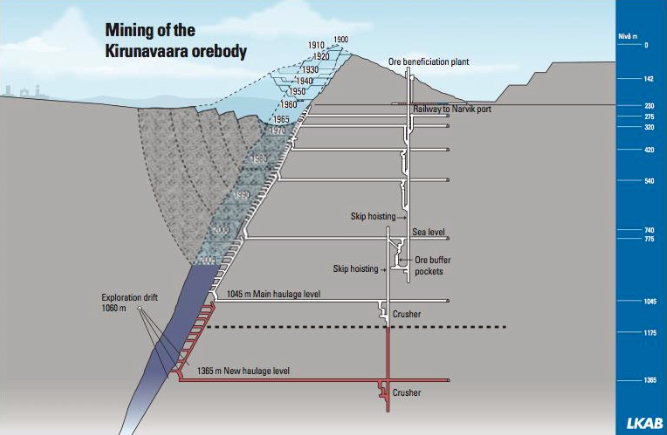

The world’s largest sublevel caving mine is located above the Arctic Circle in Sweden. The Kiruna Mine is mining the Kirunavaara iron orebody. (See figure below.) This mine is famous not only for its size and longevity, but it has been a hotbed of innovation for mining technologies over the years. I really like this figure because it tracks the mine’s development over the decades. You can see that the orebody was mined by open pit for nearly 50 years, and then they went underground. You can trace their progress over the ensuing 50 years up to the present.

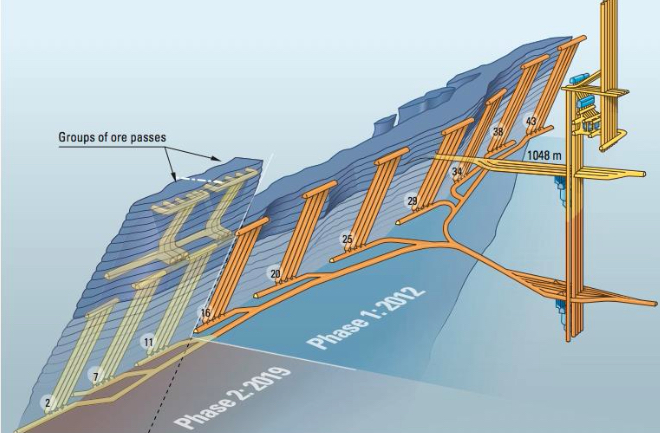

Looking at this next figure, you see the planned workings (sublevels) through 2019.

Block caving and sublevel caving require steeply dipping to nearly vertical deposits to enable the gravity flow of the rock. Longwall mining by contrast does not require this gravity flow of the caved material, and as such, it is well suited for tabular and nearly horizontal deposits.