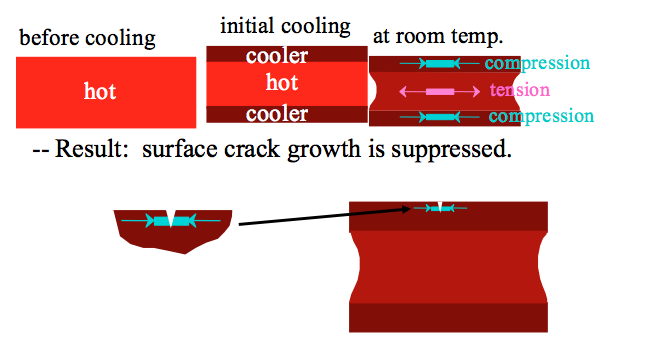

When fabricating glass, it is usually vitally important to control the cooling of the fabricated pieces. Due to the brittle nature of ceramics, failure to remove internal stress in the glass either introduced during fabrication or due to uneven cooling will likely result in catastrophic structural failure of the piece. There are two basic types of heat treatments applied to glasses. In annealing, cooling is controlled in an effort to remove (or minimize) the internal stress in the glass. This is in contrast with tempering. In tempering, compressive stress is intentionally introduced into the surface of the piece as shown in the figure below. This compressive stress can prevent surface scratches and cracks from growing, which would likely fracture the glass.

In the next section, we will discuss sintering, which is very important for particulate forming of ceramics.