Water Management Practices for Shale Energy Production

The utilization of the abundant natural gas from shale formations is desirable as a cleaner-burning form of domestically-produced energy, however, there are environmental challenges with its development, including water resource management. The approximate volume of water used during the well construction process is 100,000 gallons, primarily for drilling mud and cement. As you'll recall once the well drilling is complete, hydraulic fracturing is used to increase the permeability of the otherwise dense, tight shale to allow the hydrocarbons to be released from the shale and flow into the well. The hydraulic fracturing process involves injecting a mixture consisting of mostly water and sand along with a small proportion of other additives under high pressure through perforations in the steel casing that are connected to the surrounding shale to open up fractures. The volume of hydraulic fracturing fluids required for a horizontal well is typically about 1 to 1.5 million gallons per thousand feet of the well being fractured, so may amount to over ten million gallons per well.

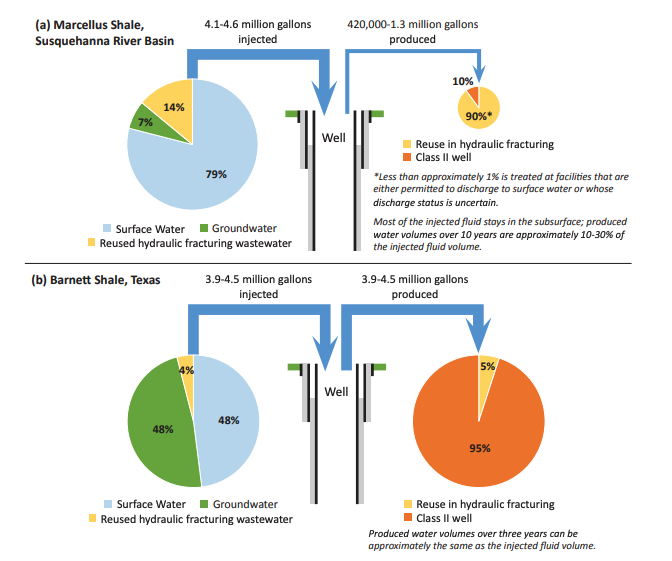

The sources of water used for drilling and hydraulic fracturing are approved by state and/or river basin commission regulators and are withdrawn from surface waters (streams, rivers, ponds, lakes, reservoirs, etc), aquifers, purchased from municipal supplies or may be sourced from municipal or industrial wastewater discharges. The amount of water that is permitted for withdrawal is typically quite small compared to the stream's or aquifer's available water to ensure that there are sufficient water resources for other uses as well as to sustain natural surface flow or groundwater levels. Different regions of the country use different sources of water for hydraulic fracturing as shown in the graphic below that compares the Marcellus shale, where mostly surface water is used, to the Barnett shale of Texas, where a mix of surface water and groundwater is used. Also, note that the Marcellus shale retains much of the fluids injected into it while the Barnett shale produces almost all of the injected fluids.

- 4.1-4.6 million gallons injected into well

- 79% Surface Water

- 14% Reused hydraulic fracturing wastewater

- 7% Groundwater

- 420,000 - 1.3 million gallons produced from well

- 90% Reuse in hydraulic fracturing*

- *Less than approximately 1% is treated at facilities that are either permitted to discharge to surface water or whose discharge status is uncertain. Most of the infected fluid stays in the subsurface; produced water volumes over 10 years are approximately 10-30% of the injected fluid volume

- 10% Class II well

- 90% Reuse in hydraulic fracturing*

B) Barnett Shale, Texas

- 3.9-4.5 million gallons injected into well

- 48% Surface Water

- 4% Reused hydraulic fracturing wastewater

- 48% Groundwater

- 3.90 - 4.5 million gallons produced from well

- 5% Reuse in hydraulic fracturing

- 95% Class II well

- Produced water volumes over three years can be approximately the same as the injected fluid volume.

The picture below shows a typical surface water intake from northern Pennsylvania. Similar surface water intakes provide about 80% of the freshwater used for shale energy development.

The video below describes water intakes for hydraulic fracturing supply. Please take a couple of minutes to watch it.

Video: Water Intake (2:28)

I'm standing along Pine Creek, which is a tributary to the Susquehanna River. Pine Creek's Valley actually forms what's known as the Pennsylvania Grand Canyon and this is an area that receives a lot of attention for its recreational opportunity. So you see people fishing and boating in the creeks, as well as hunting and hiking through the woods here. But up on the ridges along either side of the creek, there's actually been quite a bit of shale energy development, and so there are dozens of wells on top of the ridges around here. So one of the concerns is that the drilling activities could impact the water quality. And another concern is the amount of water that they actually withdraw from the creek here to serve as the water for hydraulic fracturing purposes.

The Marcellus Shale has very low permeability, but it also contains a lot of natural gas. So in order to release that natural gas from the shale, the process known as hydraulic fracturing is required to actually open up fractures in the shale and therefore allow the gas to flow out of those fractures into the wellbore and up to the Earth's surface, where it's then captured in pipes and transported to the marketplace.

A typical well site may use up to five to ten million gallons of water per well. And each well pad may have anywhere from four to ten or more wells. The millions of gallons of water used per well to fracture the shale is typically derived from surface water sources, such as Pine Creek. In fact, about 80 percent of the water used in hydraulic fracturing across Pennsylvania comes from surface water sources.

So the industry does have a permit to withdraw water from this particular location. The regulators, in this case, the Susquehanna River Basin Commission, will look at the proposed withdrawal, look at the overall flow of the stream, and determine what is a safe amount of water to withdraw from the stream, while also protecting the streams aquatic health and allow for enough water for any downstream users. Once the river's flow drops below a certain level, the industry is no longer allowed to withdraw water until the rainfall brings river flows back up to some normal level, where the industry then can resume their withdrawal practices.

Once the water is withdrawn, it is either piped or trucked to the well site for storage in steel tanks or a lined impoundment or as shown below. Modular above ground water storage facilities are becoming more prevalent as they can be erected in a short period of time (several days), and do not require as much earth-moving thus have a smaller surface footprint. The image below shows a lined impoundment that stores millions of gallons of fresh water for hydraulic fracturing operations. Once the necessary volume of water is transferred to the well site it is then withdrawn from the tanks or impoundment for use in the hydraulic fracturing process.

This video describes the use of water storage impoundments. Please take a couple of minutes to watch it.

Video: Fresh Water Impoundment (2:18)

We're standing alongside a freshwater impoundment, where the industry stores its water prior to hydraulically fracturing a well. It takes about five to ten million gallons of water to hydraulically fracture a single well. Each truck that might bring a load of water up, might bring up about 40,000 gallons of water. So if you do the math, the number of water trucks running up and down the roads here to supply enough water to fracture one well might equate to about a thousand truck trips. By piping the water, rather than trucking the water, you can save a lot of truck traffic along with the fuel to drive the trucks up and down the roads here. Not to mention the fact that, that many trucks would cause quite a disruption to anybody who's trying to enjoy the great outdoors.

So whether the water is trucked or piped, ultimately the water will need to be transferred to the nearest well pad. Oftentimes, temporary over-land pipes will be used to draw the water out of the impoundment and take it to the well pad, which might be a mile or more down the road. Another advantage of using the impoundments is that during times of drought you might not be able to draw water out of the stream or the river and therefore the industry can pull water out during higher flows, such as during the spring, and fill up these impoundments, and when they need the water later in the season, the water is already there.

You'll notice that the impoundment has a black liner. The purpose of that is to prevent the infiltration of any of that water back into the subsurface, so it's more effective at actually storing the water. Though on a sunny day like this, you may have some evaporative losses.

These freshwater impoundments are designed to do just that, store fresh water. There are certain circumstances in which the industry can store brine, that is the salt water that occurs naturally in the earth, in these impoundments. But they must have double liners, have leak detection systems, have monitoring wells, and be much more strongly engineered than just a freshwater impoundment, which really has very little potential impact on the environment.

You'll notice that the impoundment has a fence around it and that's to keep out wildlife and humans from injuring themselves.

Once the hydraulic fracturing process is complete, the well can begin to produce hydrocarbons, but also will produce a significant volume of brine from the formation during the life of the well. The next section will address how these fluids are managed to avoid impacts to water quality.