Produced Fluids Management

When hydraulic fracturing has taken place on a well, a portion of the injected fluids (typically about 5-25%), along with naturally occurring brine in the formation, will initially flow up through the well to the surface, commonly called flowback fluids. During this period, which may last for several days to a week or more, the well is allowed to flow to allow hydrocarbons to begin to be produced efficiently. Once the well has been brought on-line and producing oil or gas, the brine will be co-produced along with the hydrocarbons during a well’s productive life, and are known as produced fluids. A well will typically produce 5-10 barrels of fluids (or more) for every barrel of oil or for every million cubic feet of gas. The produced fluids typically have high concentrations of total dissolved solids (TDS). TDS may include higher concentrations of salts and metals such as barium and strontium while containing lower levels of organics and radionuclides such as radium-226. The table below provides a summary of the flowback water quality from Marcellus wells in Pennsylvania.

| Parameter | Drinking Water Standards1 | Approximate Median Concentration in Typical Pennsylvania Groundwater2 | Approximate Median Concentration in Typical Marcellus Wastewater3 |

|---|---|---|---|

| pH | 6.5 to 8.5 | 7.50 | 6.60 |

| Total Dissolved Solids | < 500 | 163.0 | 67,300 |

| Total Suspended Solids | - | 1.0 | 99.0 |

| Barium | < 2.0 | 0.070 | 686 |

| Iron | < 0.30 | 0.20 | 39 |

| Manganese | < 0.05 | 0.01 | 2.63 |

| Sodium | - | 6.87 | 18,000 |

| Hardness/td> | - | 86.1 | 17,700 |

| Strontium | - | 0.26 | 1,080 |

| Chloride | < 250 | 5.3 | 41,850 |

| Sulfate | < 250 | 18.0 | 2.4 to 106 |

| Nitrate-Nitrogen | < 10 | 0.50 | 0.1 to 1.2 |

| Bromide | - | 0.016 | 445 |

| Dissolved Organic Carbon | - | < 1.0 | 62.8 |

| Dissolved Methane | - | No data available | No data available |

| Oil & Grease | - | < 5.0 | 6.3 |

TDS levels may be 2 to 10 times the levels found in seawater, therefore they must be properly managed so they can be reused or treated to meet state regulatory requirements before discharge where allowed. Innovations in the recycling of wastewater for reuse in hydraulic fracturing have significantly reduced the volume of flowback and produced fluids that would otherwise be disposed of via surface discharge or disposal wells. Currently, it is estimated that the industry is recycling over 90% of the produced fluids for hydraulic fracturing in the Marcellus, while other basins may only see 10-20% of these fluids recycled for hydraulic fracturing. This video provides a brief overview of brine management in the Marcellus shale.

Video: Brine Production and Management (2:34)

Along with the gas that's produced out of these wells, you get brine; that is, saltwater. Keep in mind that the Marcellus was an ancient sea deposit, so there are salts trapped in the shale itself, along with deeper fluids that were injected up into the shale from a great depth, which also contained a lot of salt. So, in essence, the shale is just about saturated with salt. So when you inject the fracturing fluids down into the shale it mixes with the shale, flushes or dissolves the salt out of the shale, and as you produce gas, you're also producing brine. So for every million cubic feet of gas you produce, you produce about nine to ten barrels of brine. So in every barrel, there are 42 gallons. So you're looking at producing about 400 gallons of brine along with every million cubic feet of gas that's produced from a well. That's an awful lot of brine.

What's the industry doing with it? Keep in mind that this brine may be anywhere from two to ten times saltier than the oceans, so it can't be just dumped on the ground. The regulations dictate that the industry must either find a treatment facility that can handle the brine, use disposal wells to reinject the brine deep into the earth or recycle the brine in hydraulic fracturing operations.

Here in Pennsylvania, the industry's adopted the practice of recycling the brine. So about 85 to 90 percent of the brine that returns out of these wells can be used on another well that will be hydraulically fractured in the future. The tanks in the background actually store the brine that's produced from the wells. The gas comes out of the wells, goes through a gas water separator, and then the brine is introduced into these tanks. Whereas the gas is then introduced into the pipes, which is ultimately taken to the marketplace. The moisture must be removed from the gas so it can be used within the marketplace. So they're actually on site dehydrators, which remove as much of the moisture as possible. And then, once the gas is taken to a compressor station, there's an additional layer of dehydration. So by the time the gas reaches the marketplace, the gas is ready for use.

The benefit of recycling the produced fluids for hydraulic fracturing is that less fresh water is necessary to be withdrawn, and less water needs to be treated or disposed of. The produced fluids are separated from the oil or gas in the field and stored in tanks and then often trucked to another site for recycling or treatment, such as shown in the picture below.

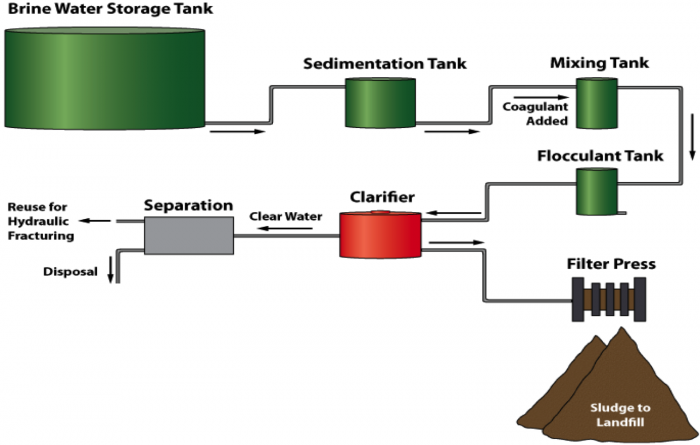

When the fluids are treated for recycling for hydraulic fracturing, they may either be treated in the field or transported to a centralized treatment facility via tanker truck. Typically the produced fluids are treated to the extent that they can be injected back down into the shale without plugging up the formation or otherwise negatively impacting oil or gas production. Often the treatment may be as simple as running the water through a filter to remove sediment, or using chemicals to remove metals via precipitation but leaving the salts in the solution. If higher levels of treatment are required to discharge to a stream or river then a desalination technique such as thermal distillation may be required to remove salts that would otherwise be toxic to freshwater species. The diagram below shows a typical treatment system for produced fluids.

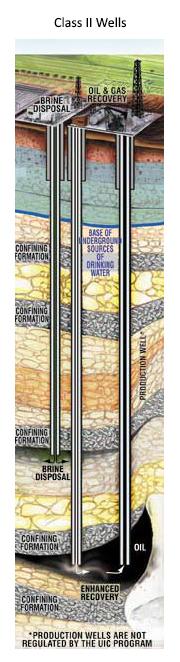

As mentioned above, not all the produced fluids can be efficiently recycled and therefore at some point will require disposal. If treated to sufficient levels, these fluids could be discharged to a stream or river if the proper permits are in place. However, this is not common in many states. A more typical way to dispose of these fluids is through deep disposal well injection, a process regulated and permitted under the EPA’s Safe Drinking Water Act. For more info go EPA: Class II Oil and Gas Related Injection Wells. Wells that are used to inject any fluid into the earth are known as Underground Injection Control (UIC) wells and are divided into six different classes. Class II wells involve oil and gas operations and include:

- Disposal wells

- Enhanced recovery wells

- Hydrocarbon storage wells

The graphic below shows Class II disposal and recovery wells. It is estimated there are about 180,000 Class II wells in the US, approximately 80% are recovery wells and 20% are disposal wells, collectively accepting 2 billion gallons per day of produced fluids.

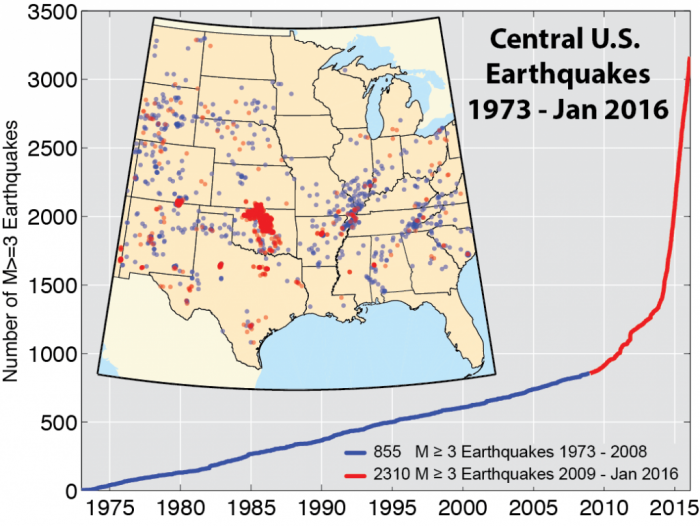

Class II disposal wells (or Class IID wells) are used to dispose of oil and gas wastes, primarily produced fluids, i.e. salt water, and are often called saltwater disposal wells. The injection rate and pressure for all injection wells must be carefully monitored to ensure fluids do not migrate into undesirable zones. When geologic faults are close enough to an injection well and the injection pressure is too high it can cause the fault to slip and thus cause an earthquake large enough to be felt at the earth’s surface. In the last several years there has been a significant increase in seismicity in some parts of the country, as shown by this USGS graphic.

In Induced Earthquakes: Myths and Misconceptions, the EPA provides a good overview of the facts and myths surrounding induced seismicity with injection wells and hydraulic fracturing.

Clearly, we need to make sure that oil and gas development is occurring using the best available technologies to reduce the industry’s overall environmental footprint, yet meet our society’s energy needs. We will explore some of the environmental impacts that oil and gas development can have and the best management practices to prevent them.