Protecting Water Resources and the Environment

The development of shale energy resources has created concern about potential impacts on the environment, while also leading to a societal awakening for the protection of our natural resources, especially water resources. There are potential impacts to the environment, for example, if a spill of fracturing fluids occurs or a shale gas well is not constructed properly, water resource impacts could occur. On the other hand, shale gas has a lower carbon and water footprint than other forms of fuel. So while not perfect, it can be argued that it is a cleaner source of energy if developed properly.

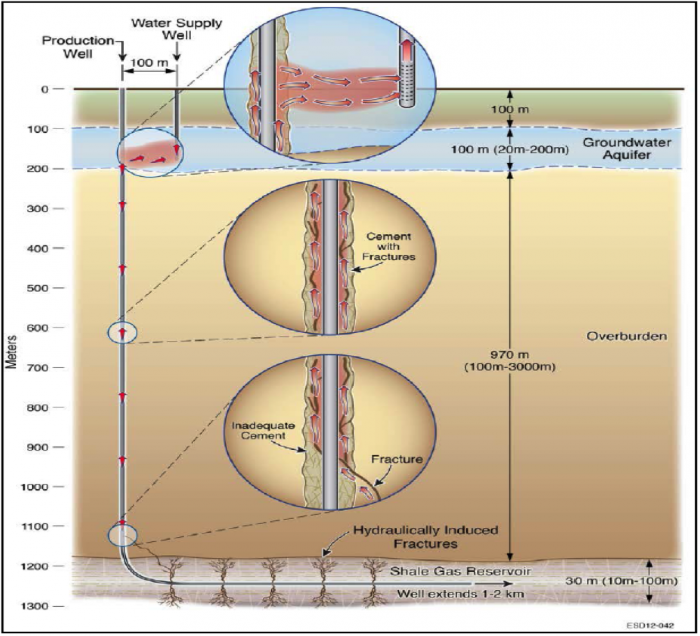

There are multiple waste streams that result from shale energy development. These include solid wastes such as drilling cuttings and sludge from wastewater treatment and liquid waste streams such as flowback and produced fluids. Therefore proper treatment and disposal are critical. There are also phases during the drilling and fracturing operations that could lead to water contamination. For example, the shale gas drilling and well construction process have led to methane migration, where private wells have increased levels of methane originating from shale wells that were not properly sealed, thus allowing methane to get into groundwater. The picture below shows how methane migration could occur when the cement seal is not properly emplaced.

Methane migration (aka stray gas) has been especially problematic in some of the early Marcellus shale wells drilled in northeastern Pennsylvania. In this area, shallow gas was present in the upper 3000’ feet of the Earth, but not adequately sealed off during shale gas well drilling, and leaked off into private wells in some cases. Through 2015 about 38 shale gas wells had impacted approximately 108 private wells in Pennsylvania, however stronger well construction regulations has led to no new cases of methane migration in the last several years. To put this in context, there are approximately 11,500 shale wells currently drilled in Pennsylvania. Therefore 99.7% of the wells drilled had no reported methane migrations issues, but the 0.3% that required remediation was surely a major inconvenience to those homeowners involved. Remediation typically involves injecting cement into the leaking zone to seal off the leaking methane. Here is a picture of someone’s groundwater supply that had been impacted by methane, as well as potentially by drilling foam in NE Pennsylvania. Surely you would not want to drink this!

The United States Environmental Protection Agency (EPA) has studied the risks to drinking water from hydraulic fracturing as summarized in the report Hydraulic Fracturing Study - Final Assessment 2016. To date, there have been no documented cases of hydraulic fracturing fluids migrating up from the zone in the shale where fracturing occurs and leaking into a drinking water supply. However, there is no shortage of public concern about this occurring. There are other risks that are real and have been documented. Perhaps the biggest risk to impacting water resource quality from shale energy development is surface spills of fracturing or produced fluids. There are large volumes (millions of gallons) of fluids being handled during a fracturing job and spills can occur, whether via mechanical failure or human error. While any form of drilling and oil and gas production does have inherent risks, there are many engineering practices that can minimize these potential risks. This video by Dr. Terry Engelder discusses the risks with shale energy development.

Video: Water Risks (1:23)

David Yoxtheimer: A common concern by the general public is the potential for hydraulic fracturing to impact drinking water supplies. Is there really significant concern to be had there?

Terry Engelder: The answer is yes and no. First, let me say that there is a significant chance for contamination to occur and that occurs because of surface spills. And agencies, like the Department of Environmental Protection in Pennsylvania, worked very hard with the operators to mitigate and prevent surface spills. And the reason for surface spills being an issue is that water typically flows downhill, downward into the ground. So then the second half of the question, of course, is, "Will water down two kilometers below the surface of the earth flow upward from the hydraulic fracture treatment and contaminate groundwater?", and it's very important to appreciate that water does not flow uphill and is very unlikely to contaminate groundwater from below. And this is the reason why the Pennsylvania Department of Environmental Protection spends so much time working with the operators to prevent those surface bills. They're the ones that can potentially contaminate groundwater, not water coming from below flowing uphill. Water doesn't do that.

One of the most important means to ensure oil and gas development does not impact someone’s water supply is to collect pre-drilling water samples from their supply to establish baseline conditions. If there is a suspected problem after drilling or fracturing, then additional samples can be collected to determine if there is an issue related to the oil and gas operation. If high levels of certain parameters associated with shale gas development occur in a private water supply after nearby oil and gas development, such as methane, chlorides, barium, strontium, or other parameters, then there may have been some impact and remedial measures would need to be taken immediately. Again, although this is not common, it is much easier to prevent contamination than to clean it up. Some of the best management practices that the industry are now using to prevent spills and contamination include pre-drilling water supply monitoring, lining well pads to capture spills, and better well construction practices. As a citizen, if there is potential for drilling in your area become engaged in the process by contacting your regulator, attending public meetings, and being aware of drilling operation locations. Allow the oil and gas company contractors to sample your water at their cost and pay attention to the appearance, color, and taste of your water. If there is a change you will be able to detect it early and contact the regulators immediately to have it tested.