8.6. Bio-mass Fueled Combined Heat and Power Systems

Biomass as a source of fuel has been part of the global energy economy throughout human history. Using biomass as fuel (via combustion) may help solve the fuel supply issue, since biomass is renewable, but does not help solve the global carbon emission and pollution problem: burning biomass produces CO, CO2, NOx, and other gases at the levels exceeding those from traditional fossil fuels (e.g., oil, gas).

Indirect utilization of biomass implies the production of various biofuels (for example, ethanol), which can be converted to energy in a cleaner way. Types of biomass currently on market and ways to produce them are well described in the Biomass Wikipedia article

Biomass combined heat and power (CHP)

Biomass-fueled CHP or cogeneration is one of the applied technologies developed as a cost-effective method of energy recovery. Because the by-product heat generated in electricity generation is not wasted, but rather utilized as thermal energy, the total efficiency of such systems reaches 60-80%.

There are three main stages in the biomass-fueled CHP process:

- biomass collection and preparation

- biomass conversion: (i) to steam or (ii) to biogas

- power and heat generation

These three stages are integrated in one installation.

The following bio resources are considered for energy recovery:

- energy crops and crop residues

- forest residues and wood waste

- manure biogas and wastewater treatment biogas

- food processing residue

- municipal solid waste (MSW)

- landfill gas

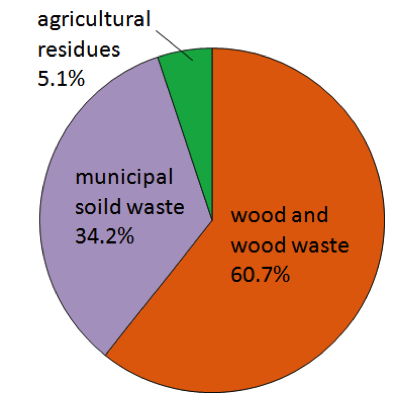

Wood products currently make up the dominating stock in U.S. (Figure 8.8).

These different biomass resources require somewhat different approaches to the collection, storage, and conversion. In brief, there are two main categories of biomass conversion systems, as outlined in the table below:

| Direct-Fired Systems | Gasification Systems | |

|---|---|---|

| Process and Output | burning biomass in a boiler to produce high pressure steam | decomposing biomass to produce gaseous fuel - syngas |

| Feed | bark, chips, sawdust, end cuts - wide variety of fuels | shipped wood, rice hulls, shells, sewage sludge, wood residues |

| Output | high pressure steam | syngas fuel |

| Capacity | up to 300 MW | up to 50 MW |

| Notes | Direct-fired systems perform combustion of the solid biomass and produce hot flue gases that heat the boiler. This technology is dated back to 19th century. There are many different kinds of boilers, based on configuration, size, quality of steam. The two most common types of boilers are stockers and fluidized bed boilers. Boiler size is often measured in terms of fuel input in MMBtu per hours. Biomass fuels can be combusted separately in boilers or co-fired with coal and other conventional fuels. [US EPA, 2007] | "Biomass gasification involves heating solid biomass in an oxygen-starved environment to produce low or medium calorific gas. Depending on the carbon and hydrogen content of the biomass and the gasifier’s properties, the heating value of the syngas, can range from 100 to 500 Btu/cubic foot (10 to 50 percent that of natural gas)." The main combustible components of syngas are CO and hydrogen, and the main incombustible component is CO2. Biomass gasification offers certain advantages over directly burning the biomass because the gas can be cleaned and filtered to remove problem chemical compounds before it is burned. Gasification can also be accomplished using chemicals or biologic action (e.g., anaerobic digestion); however, thermal gasification is currently the only commercial or near commercial option." [US EPA, 2007 ] |

Chapter 5 of the EPA report on CHP biomass technology provides a good amount of technical details as for how these conversion methods work.

Reading assignment:

EPA Report: Biomass Combined Heat and Power Catalog of Technologies, U. S. Environmental Protection Agency, Combined Heat and Power Partnership, September 2007. Chapter 5: Biomass Conversion Technologies, pp. 30-61.

While reading, try to find answers to the following questions:

- What are basic technical principles of the direct-fired and gasification biomass conversion systems?

- How do these systems compare in size and efficiency?

- What is fluidized bed technology? How is it different from the fixed bed system and what advantages does it offer?

- What biomass conversion systems are most cost-effective?

Commercialization status

Biomass is used in the original solid form or can be gasified or converted to liquid fuels. There are a number of commercialized and emerging technologies to foster that conversion (Tables 8.4 and 8.5).

| Energy Conversion Technology | Conversion Technology Commercialization Status | Integrated CHP Technology (Prime Mover) | Prime Mover Commercialization Status |

|---|---|---|---|

| Anaerobic Digestion | |||

| Anaerobic digester (from animal feeding operations or wastewater treatment facilities) | Commercial technology | Internal combustion engine | Commercial technology |

| Microturbine | Commercial technology | ||

| Gas turbine | Commercial technology | ||

| Fuel cell | Commercial introduction | ||

| Stirling engine | Emerging | ||

| Direct Combustion - Boilers | |||

| Fixed bed boilers (stoker) | Commercial technology - Stoker boilers have long been a standard technology for biomass as well as coal, and are offered by a number of manufacturers. | Steam turbine | Commercial technology |

| Fluidized bed boilers | Commercial technology - Until recently fluidized bed boiler use has been more widespread in Europe than the United States. Fluidized bed boilers are a newer technology, but are commercially available through a number of manufacturers, many of whom are European-based. | ||

| Cofiring | Commercial technology - Cofiring biomass with coal has been successful in a wide range of boiler types including cyclone, stoker, pulverized coal, and bubbling and circulating fluidized bed boilers. | ||

| Modular (small, packaged, pre-engineered systems [<5 MW]) direct combustion technology | Commercial technology - small boiler systems commercially available for space heating. A small number of demonstration projects in CHP configuration. | Small steam turbine | Commercial technology |

| Organic Rankine cycle | Emerging technology - Some "commercial" products available | ||

| "Entropic" cycle | Research and development (R&D) status | ||

| Hot air turbine | R&D status | ||

Credit: USA EPA, 2007

| Energy Conversion Technology | conversion Technology Commercialization Status | Integrated CHP Technology (Prime Mover) | Prime Mover Commercialization Status | ||

|---|---|---|---|---|---|

| Gasification | |||||

| Fixed bed gasifiers |

Emerging technology - The actual number of biomass gasification systems in operation worldwide is unknown, but is estimated to be below 25. A review of gasifier manufacturers in Europe, USA and Canada identified 50 manufacturers offering commercial gasification plants from which 75 percent of the designs were fixed bed; 20 percent of the designs were fluidized bed systems. |

Gas turbine - simple cycle |

Prime movers have been commercially proven with natural gas and some medium heating value biogas. Operation on low heating value biogas and the effects of impurities on prime mover reliability and longevity need to be demonstrated. |

||

| Fluidized bed gasifiers | Gas turbines - combined cycle | ||||

| Large internal combustion (IC engines | |||||

| Modular (small, packaged, pre-engineered systems [<5MW]) hybrid gasification technology | Emerging technology - A small number of demonstration projects supported with research, design, and development funding. | IC engine | Commercial technology - But operation on very low heating value biogas needs to be demonstrated. | ||

| Microturbine | |||||

| Fuel cell | Commercial introduction | ||||

| Stirling engine | Emerging technology | ||||

| Modular (small, packaged, pre-engineered systems [<5MW]) hybrid gasification/combustion | Emerging technology - Limited commercial demonstration. | Small steam turbine | Commercial technology - But integrated system emerging. | ||

Credit: USA EPA, 2007

Social considerations

While the biomass energy offers benefits in terms of sustainable fuel supply, it can potentially aggravate the air pollution problem. Except for a very narrow range of applications of biofuels in no-combustion devices, such as fuel cells (which can generate electricity electrochemically with bio-hydrogen and syngas), most of the biomass energy technologies involve burning the fuel and result in greenhouse gas emissions. This drives public opinion away from biomass options towards such alternatives as solar and wind energy. The second issue debated is the potential competition for land use between the energy and food crops.

More information on the environmental issues associated with renewable energy technologies is included in the next page of the lesson.