8.1.2: Revisiting "The Quest for Continuous"

In a previous lesson on “the quest for continuous,” we looked at the motivation for replacing conventional cycles and the equipment for doing so. In the case of shaft sinking, the same principles have been applied. A variety of boring machines has been developed, and consist of a rotating and bit-laced head, a built-in materials handling system to clear the cut material and send it on its way to the surface, and the means for advancing, guiding, and controlling the borer. Likely, there are stages immediately above the borer that are outfitted to allow placement of liners. The following video clip (10:35) provides a detailed look into the functionality of a modern shaft boring machine.

In soft to medium harness rock, the boring machine is the preferred choice, as it can be done faster and at a lower cost than with conventional methods. However, in hard materials, a conventional drill and blast cycle is the only viable choice. This is similar to what we find for continuous mining methods in various deposits. There is one other machine of note for smaller diameter shafts – the raising boring machine.

Small diameter shafts, say less than 10’ in diameter, are required in many applications. They are used for emergency escape hoists, ventilation shafts, and travel ways between levels in a mine. The latter are known as raises, and this is where the name, raise borer, originated. In the good old days, raises and small diameter shafts were driven using conventional cycles. Today, a continuous cycle is used in most cases.

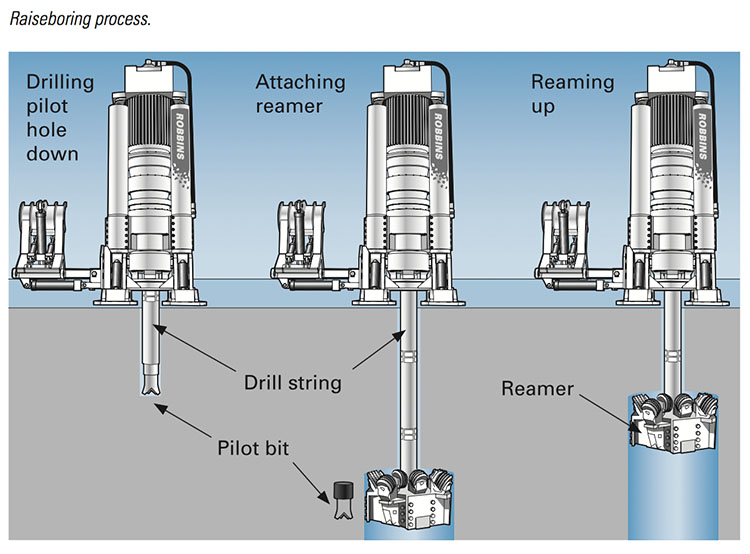

Raise boring requires that the bottom of the raise terminates in an existing mined opening. The first step in using a raise borer is to drill a pilot hole down to the exiting opening. Once completed, a large diameter cutting head is threaded onto a drill steel that connects to a power source on the surface or the upper level. The power source, i.e., the raise borer, provides thrust and rotation for the cutting bits. The cuttings fall to the lower level where they must be loaded and hauled. Take a look at this figure – it makes more sense if you can see it!

Here is a picture of the power unit. Raise borers can excavate an inclined open as well as vertical, and they can bore upward, although that is done with less frequency.