First and foremost, a product must make economic sense. The price of a product must be attractive to customers, and it must return a sustainable profit to the company. To minimize product costs, materials engineers should consider three factors: component design, material selection, and manufacturing technique. Also, there could be other significant costs including labor and fringe benefits, insurance, profit, and costs associated with regulatory compliance. As the world has become more populated and that population is increasing its usage of the earth's natural resources, engineers are increasingly being asked to consider sustainable practices when developing new products. Also, since it is estimated that approximately half the energy consumed by the U.S. manufacturing industry is used to produce and manufacture materials, the efficient use of energy for manufacturing processes and utilization of sustainable energy sources when available is highly desirable.

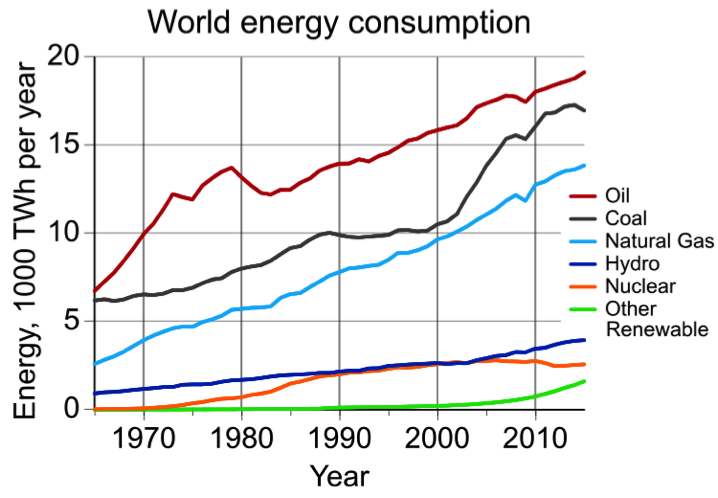

| Year | Energy, 1000 TWh per year |

|---|---|

| 1970 | 10 |

| 1980 | 13 |

| 1990 | 14 |

| 2000 | 16 |

| 2010 | 18 |

| Year | Energy, 1000 TWh per year |

|---|---|

| 1970 | 6 |

| 1980 | 8 |

| 1990 | 10 |

| 2000 | 11 |

| 2010 | 16 |

| Year | Energy, 1000 TWh per year |

|---|---|

| 1970 | 4 |

| 1980 | 6 |

| 1990 | 7 |

| 2000 | 9 |

| 2010 | 13 |

| Year | Energy, 1000 TWh per year |

|---|---|

| 1970 | 1 |

| 1980 | 2 |

| 1990 | 2.5 |

| 2000 | 3 |

| 2010 | 4 |

| Year | Energy, 1000 TWh per year |

|---|---|

| 1970 | 0 |

| 1980 | 1 |

| 1990 | 2.5 |

| 2000 | 3 |

| 2010 | 3 |

| Year | Energy, 1000 TWh per year |

|---|---|

| 1970 | 0 |

| 1980 | 0 |

| 1990 | ~.1 |

| 2000 | ~.1 |

| 2010 | 1 |

Sustainability represents the ability to maintain an acceptable lifestyle at the current level and into the future while preserving the existing environment. Your textbook discusses one approach to achieving sustainability: green product design. In the next section, we will look at some green design principles and examples of their application. Before moving on to that section, please watch the following short video. This (1:53) video on using renewable feedstock to replace nonrenewable starting raw materials highlights a green design principle used to make processes more sustainable.

To Watch

So far, many of our plastic products are derived from crude oil, which is a non-renewable source. We cannot grow or produce crude oil. This means we do not have an infinite supply of it. Instead, we must wait millions of years in order for dead carbon-based living organisms to be compressed by layers and layers of sediment before we get crude oil.

The term renewable feedstock the raw material that can be grown or produced by humans. The usage of renewable feedstock is attractive because it reduces the amount of harmful waste produced by the crude oil refinery and distillation processes.

Most printer inks are made from crude oil-derived pigments. If you think about the amount of printing that is done on a global scale this can be a problem in the long term. Currently in development are soy-based inks, which are derived from the oil of the soybean plant. As a plant, soybeans are a renewable resource.

The production process of these inks is overall more environmentally friendly than their petroleum-based counterparts. Also, the soy-based inks are much brighter than the petroleum-based inks. The recycling process of paper products printed with soy-based inks is also considerably more environmentally friendly. When paper products are recycled the inks need to be removed. Petroleum inks can be difficult to remove but soy-based inks can be removed with relative ease.

The term renewable feedstock refers to raw material that can be grown or produced by humans. The usage of renewable feedstock is attractive because it reduces the amount of harmful waste produced from the crude oil refinery and distillation processes. Most print inks are made from crude oil derived pigments. If you think about the amount of printing that is done on a global scale, this can be a problem in the long term.

Currently in development are soy-based inks which are derived from the oil of the soybean plum. As a plum, soybeans are a renewable resource. The production process of these inks is overall more environmentally friendly then their petroleum-based counterparts. Also, these soy-based inks are much brighter than the petroleum-based inks.

The recycling process of paper products printed with soy-based inks is also considerably more environmentally friendly. When paper products are recycled, the ink needs to be removed. Petroleum inks can be difficult to remove, but soy-based inks can be removed with relative ease.