5.1.2: Materials Handling

Materials handling is concerned with how we move (haul) the mined material out of the mine to the processing plant. Before looking at specific haulage options, we should talk about a few overarching concepts. The first is intermediate haulage.

At the working face, i.e., where the ore is being freed from the deposit, we are going to load the ore into some type of haulage. If we are in a surface mine, it is likely that we’ll load the ore into a truck, which will haul the ore the entire way to the plant, dump it, and then return to the face for another load. If we are in an underground mine, it is likely that the material at the face will be loaded into a haulage vehicle and then transported to an intermediate dumping point. From the intermediate point, a different haulage device will be employed. Sometimes, there could be even another subsequent intermediate device. As an example, assume we have a mine in which LHDs are used to load out the ore at the draw point (face) and transport it to a dump. The dump point is at an ore chute in the rock that funnels the ore to a lower level where it is loaded into rail cars, along with the ore from many other dump points. A train may pull these cars several miles out of the mine and to a processing plant. Or, the train may take the ore to a transfer point at the bottom of the shaft, where the ore will be dumped and transported in large ore skips (buckets) up the shaft to the surface. The choice of a specific type of materials handling is based on optimizing the overall process. Smaller and maneuverable equipment is best suited at the face, whereas larger capacity, but more permanent equipment may be indicated to move the material out of the mine. As we look at different mining methods, this will become even clearer.

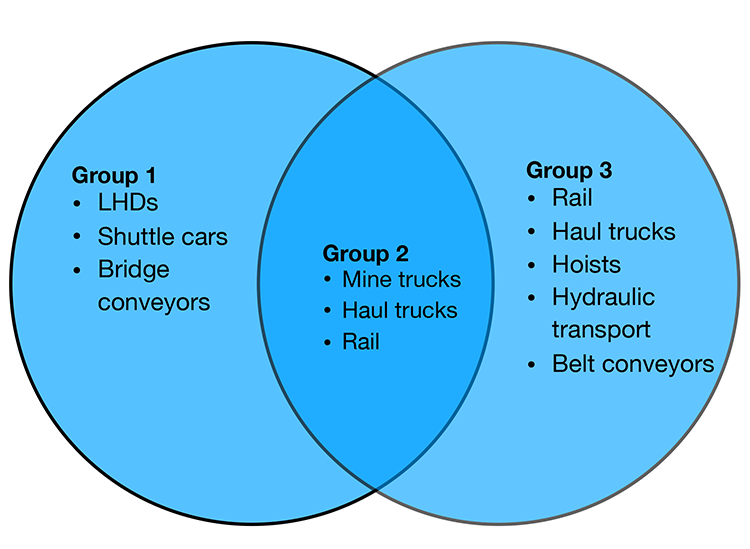

Let’s identify the common choices for materials handling, to move material from the face to the plant.

Click here to see a text description.

- Group 1

- LHDs

- shuttle cars

- bridge conveyors

- Group 2

- mine trucks

- haul trucks

- rail

- Group 3

- rail

- haul trucks

- hoists

- hydraulic transport

- belt conveyors

I’ve arranged them into three groups. The equipment in the first group is typically used for short haulage runs from the face to an intermediate dump or transfer point. The equipment in the third group is used to move the material out of the mine and to the plant. The equipment in the second group can fall into Groups I or III. In some instances, the equipment shown in Group II will be used to move the material directly from the face to the plant, whereas in others, it will be used to transfer the ore to an intermediate point. Again, the choice and rationale will become clearer as we learn about the requirements inherent to the different mining methods. Let’s look at the general characteristics of these materials-handling modes. We’ve already discussed LHDs, so let’s begin with shuttle cars.