5.1.1b: Loading, Draglines, Shovels, and Hydraulic Excavators

You’ll recall that the production cycle for harder ores is drill-blast-load-haul; while for softer ores, it is excavate-load-haul. I am emphasizing load because I want to talk about the equipment used for loading. In harder ores, the material is broken free of the orebody by drilling and blasting. Once it is freed, it usually must be loaded into something so that it can be hauled out of the mine. In softer ores, if a ripper is used, the broken ore will require loading. In softer ores, it is often practicable to free them from the orebody by digging or excavation, without the need to drill and blast. Once freed, the ore is usually loaded into something so that it can be hauled out of the mine. By the way, I am using the word something to describe the haulage out of the mine. I’ll be more specific shortly when we look at haulage.

The reason for this quick review of the difference in production cycles is because the equipment used in loading harder ores is sometimes used for both excavating and loading softer ores. I want you to be aware of this now so that you are not confused when we encounter this with certain pieces of loading equipment.

Draglines

Draglines have the ability to excavate huge quantities of material and then to place that material at quite a distance from the dragline itself. Here are some of the more important characteristics of draglines.

- The drag bucket is filled by pulling (dragging) the bucket towards the dragline.

- The dragline can only dig at a level below the level at which the dragline is sitting.

- The drag bucket is outfitted with “teeth” to aid excavation, but even so, it is only effective in softer materials or materials that have been blasted.

- The size of the dragline is based on the capacity of the drag bucket. A 15 yd dragline has a bucket capacity of 15 yd3. Typically draglines are in the range of 60 – 150 yd. The largest one ever built had a bucket capacity of 220 yd3. It could fill the bucket, swing it to the dump point nearly 300’ from the machine, dump the bucket, and return to begin the cycle over again in 45 seconds!

- The reach of the dragline determines the distance from the machine that material can be dumped. The maximum reach is approximately 450’.

- The weight of the dragline is so great, approaching 8000 tons in the larger units, that crawler tracks are used on only the very smallest draglines, and instead, they sit on two large “shoes” to distribute the weight. The shoes are attached to powered eccentric cams that allow the dragline to walk as mining advances.

Draglines are commonly used to remove the overburden, also known as stripping, in open cast mining. In many cases, the overburden is drilled and blasted to facilitate removal by the dragline. Occasionally, the dragline will be used to remove the ore as well.

Shovels

Shovels have the ability to load large quantities of material, but less than draglines. A major difference between a shovel and dragline is that a shovel loads material at the same level as the shovel is sitting up to the height of the shovel’s boom. Here are some additional characteristics of shovels.

- The shovel’s dipper is filled by pushing the dipper into a bank of material. This action is known as crowding.

- The dipper is outfitted with “teeth” to aid excavation, but even so, it is only effective in softer materials or materials that have been blasted.

- The size of the shovel is based on the capacity of the dipper. A 12 yd shovel has a dipper capacity of 12 yd3. Typically, shovels are in the range of 10 – 90 yd.

- The digging height of the shovel is determined the size of the boom.

- Shovels are mounted on large crawler tracks, to facilitate movement into the bank, known as propelling; as well as to allow the shovel to move to the working faces or banks.

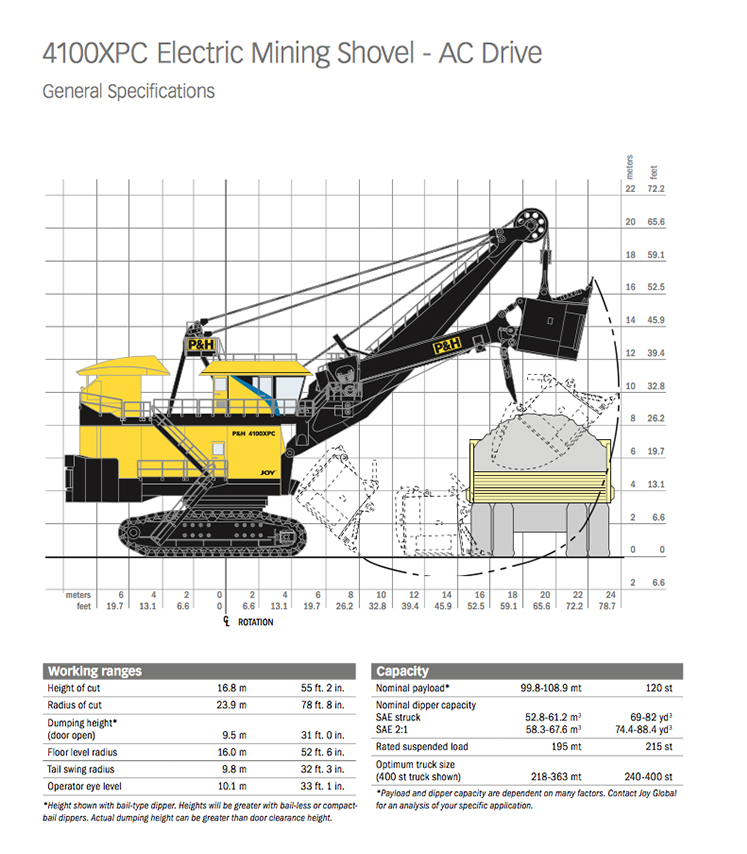

Large shovels are used for overburden removal, and in this application are known as stripping shovels. Perhaps more commonly, they are used to load ore into trucks. The relationship of key shovel parameters is illustrated in this diagram. Also, I’d like you to take notice of the wire ropes that are used to control the boom and the dipper. This is the original configuration for shovels. Over the past three decades, a modification of the shovel, using hydraulics cylinders instead of wire ropes, has become increasingly popular. Let’s take a look at it next.

Hydraulic Excavators

This class of loader had its origin with machines that looked like this. These excavators had the advantage of being able to excavate or load below or above the level at which the machine is sitting. They also have the ability to be rather selective in what they remove.

These excavators have gotten much larger over the years and have buckets of 40 yd3 or more, and a reach of 60’ or more.

The wire ropes on electric shovels have been replaced with hydraulics, and this has led to hydraulic excavators that look like this, and are often called hydraulic shovels. By replacing the wire ropes, additional degrees of freedom can be incorporated into the machine, resulting in better performance.