5.2.4: Ventilation

Fresh air is required to provide oxygen and to carry away carbon dioxide. Large quantities of air are often required to dilute, render harmless, and carry-away dangerous dusts and gases. Methane is an explosive gas associated with coal deposits, among others. Sufficient air must be coursed through the coal mine to keep the methane concentration well below the lower explosive limit. Hydrogen sulfide, a deadly gas, forms under certain conditions in underground metal mines and must be diluted to render it harmless. Carbon monoxide and oxides of nitrogen are produced during blasting, and these toxic gases must be diluted and carried away before miners return to continue the production cycle. The concentration of respirable silica dust, i.e., dust small enough to become trapped in the lungs, is produced during mining and can lead to fatal lung diseases when inhaled over years of work. Accordingly, the allowable concentration of respirable dusts is heavily regulated and controlled, and providing sufficient air to carry away these dusts is important. We could go on with the examples, but you get the idea!

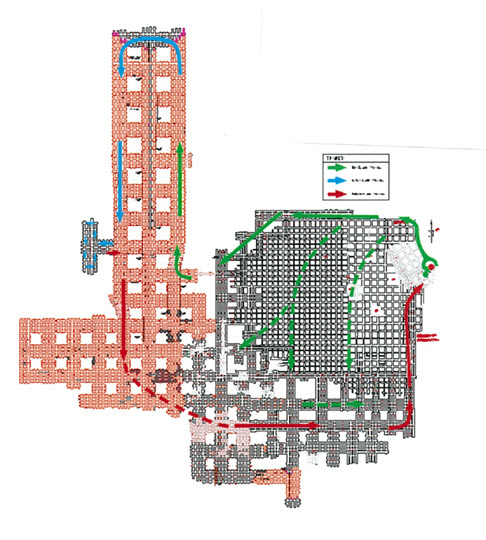

It is easy to understand the need to provide large quantities of air, sometimes on the order of several hundred thousand cubic feet per minute! It is not so easy to control that air, to get the right amounts to the different parts of the mine, and then to move the “dirty air” to outside of the mine. It takes significant engineering, and many control devices, to achieve the intended outcome. If you look, for example, at this plan view of a mine, below, you can see the many passageways. It resembles the streets and avenues of a city. Now imagine that you have one or two entry points for fresh air, as provided by fans, and you have a few exit points where the exhaust air is ventilated to the outside. All that you have to do is to make sure that the proper quantities are flowing in each of the “streets” and “avenues.” Further, you have to do this on an ongoing basis, since the layout of the mine changes from day-to-day as mining advances. No small feat…! Depending on the mining plan, you can build stoppings, i.e., solid barriers to divert air, you can hang curtains to divert air, you can install and adjust regulators to control pressure drops and the attendant airflows, and you move auxiliary fans and tubing to further direct airflows to where they are needed.

When we looked at ground control, we identified the importance of inspection, as the first step in that auxiliary operation. Similarly, with ventilation, there is a “check” that occurs as a prerequisite to certain unit operations. Gas measurements may be required as well as air quantity determinations. It may be necessary to adjust the ventilation system as a result of these measurements or to change the production plans until adequate ventilation can be provided.

Our discussion has focused on ventilating underground mines, and indeed that’s where most of the action is to be found. Interestingly, surface mines occasionally experience challenging ventilation problems. Some open pit mines, for example, are deep enough that temperature inversions can occur, in which air in the pit is trapped by a cooler and heavy layer of air near the top of the pit. The diesel fumes from the heavy equipment operating down in the lower levels of the pit can build up to dangerous levels. Utilizing artificial ventilation in this circumstance, whether the wind induced from the blades of a helicopter hovering over the pit or large axial vane fans, is essential to protecting the health of the miners and ensuring that production can continue.

Ventilation, as with ground control, is a crucial auxiliary operation.