Optical Profilers

Optical profilers are interference microscopes, and are used to measure height variations – such as surface roughness – on surfaces, with great precision, using the wavelength of light as the ruler.

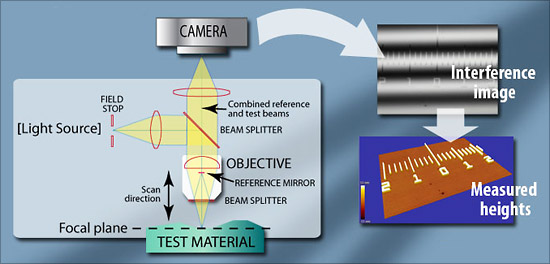

Optical profiling uses the wave properties of light to compare the optical path difference between a test surface and a reference surface. Inside an optical interference profiler, a light beam is split, reflecting half the beam from a test material which is passed through the focal plane of a microscope objective, and the other half of the split beam is reflected from the reference mirror.

Constructive interference occurs when the phase difference between the path lengths is a multiple of 2π, whereas destructive interference occurs when the difference is an odd multiple of π.This creates the light and dark bands known as interference fringes.

Since the reference mirror is of a known flatness, that is, it is as close to perfect flatness as possible, the optical path differences are due to height variances in the test surface.

This interference beam is focused into a digital camera, which sees the constructive interference areas as lighter, and the destructive interference areas as darker.

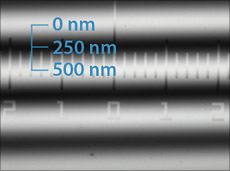

In the interference image (an "interferogram") below, each transition from light to dark represents one-half a wavelength of difference between the reference path and the test path. If the wavelength is known, it is possible to calculate height differences across a surface, in fractions of a wave. From these height differences, a surface measurement – a 3D surface map, if you will – is obtained.

Hypothetically, if the wavelength is 500 nanometers, one could estimate the distance of slope over a full wavelength by looking at the light and dark interference bands – known as interference fringes – in an interferogram. Optical profilers calculate these differences much more accurately than is possible by visual methods.

In practice, an optical profiler scans the material vertically. As the material in the field of view passes through the focal plane, it creates interference. Each level of height in the test material reaches optimal focus (and therefore greatest interference and contrast) at a different time. With well-calibrated optical profilers, accuracy well below a nanometer is possible.

Optical profiling can be used to measure surface finish, roughness, and shape on many surfaces, so long as enough light is reflected back into the objective from the surface.

Much of the content was taken from Zygo's Optical Profiler Basics Webpage