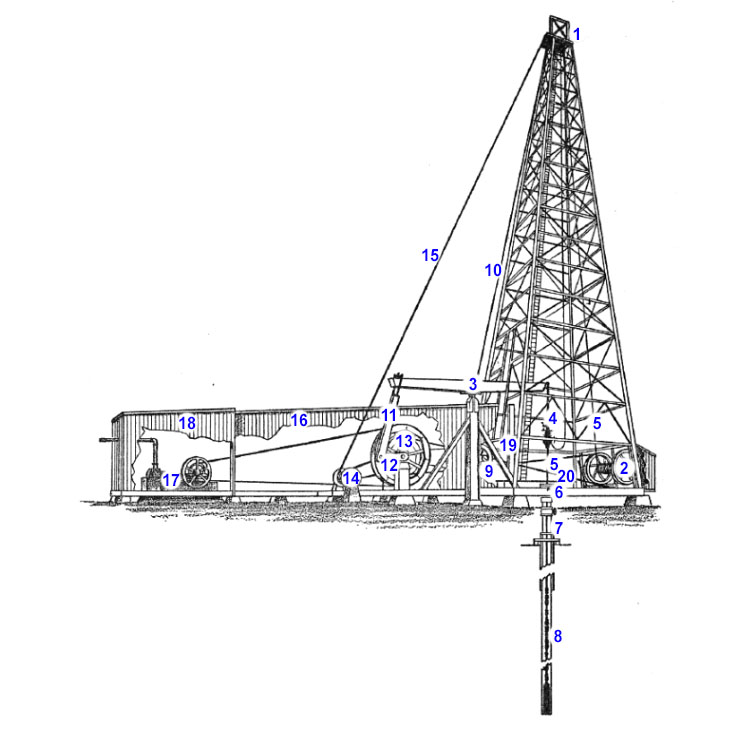

Cable tool rigs were the first drilling rigs used for hydrocarbon wells. They were used in the United States in the second half of the nineteenth century (1800s) to drill shallow hydrocarbon wells in the Appalachian Region. While these rigs are no longer used in modern oil and gas well drilling, they are of historical note. Cable tool rigs were originally used in the United States for drilling water wells in the early 1800s but had their origins in the percussive drilling techniques used by ancient Chinese and Persian civilizations. They were adapted in the mid- to late-1800s for drilling hydrocarbon wells. Figure 8.02 provides an illustration of a cable tool drilling rig.

| Diagram | Index |

|---|---|

|

|

| Cable-tool drilling is done by raising and dropping a string of tools on the end of a cable. The up and down motion is imparted by the walking beam. The tools are pulled from or lowered into the hole by winding or unwinding the drill cable on the bull wheel. Casing is raised or lowered by the casing line and calf wheel. The cuttings are removed from the hole by the bailer, which is raised and lowered by the sand line and reel. | |

| Source: Ball, M. W.: This Fascinating Oil Business, The Bobs-Merrill Company, p. 103 (Cable Tool Drilling Rig) |

|

The cable tool itself is essentially a heavy metal chisel that is suspended from a wire cable which, in turn, is attached to a spring pole or Walking Beam (similar to a lever and fulcrum system). The cable tool is repeatedly raised, using the spring pole or walking beam, and allowed to drop (free fall) down the wellbore causing the rock to fail at the point of impact at the bottom of the hole. When enough rock fragments accumulate at the bottom of the wellbore, water is poured into the hole, and Bailers are lowered to remove the rock cuttings and debris.

Historically, bailers were simply buckets used to lift the debris from the wellbore to the surface. Modern bailers are tools which are run on wireline or slickline with a sealed compartment at low pressure. When the compartment is opened, the surge of fluids at hydrostatic pressure into the low-pressure chamber carry the sand and drilling debris into the bailer. The tool is then lifted to the surface.

Cable tool rigs are of historical note because Colonel Drake’s well in Titusville, PA (considered the first well drilled with the specific objective of producing oil) was drilled with a cable tool rig in 1859 to a depth of 69.5 ft. The drilling of Drake’s Well is considered to be the start of the modern oil and gas industry. Cable tool rigs began to be replaced with rotary drilling rigs in the 1890s.