A jack-up rig is a floating drilling rig with (typically) three retractable legs which can be raised while the rig is moved onto location (either self-propelled or towed) and lowered into the seabed to jack-up (lift) the rig to a safe height above the water level, cantilever the rig to the desired surface location of the well, and provide a stable platform for drilling operations. Figure 8.10 shows a jack-up rig with its legs retracted being towed onto location.

When on location, the legs are lowered until they reach the seabed. Once the legs reach the seabed, further extension allows the rig itself to be raised to the desired height above the water level and preparations for drilling can be commenced. The legs on a jack-up rig can be up to 500 ft. in height. Considering a 100 ft air space between the waves and hull of the rig, this allows for water depths of approximately 400 ft for drilling operations. The rotary rig on a jack-up rig can either be a conventional kelly drive rig or a top-drive rig.

Jack-up rigs are used to drill wells in shallow waters, typically less than 400 ft of water, and can be used to drill wells to a Total Depth (TD) of 30,000–35,000 ft. Due to their mobility, jack-up rigs can be used to drill exploration wells, appraisal wells, and development wells.

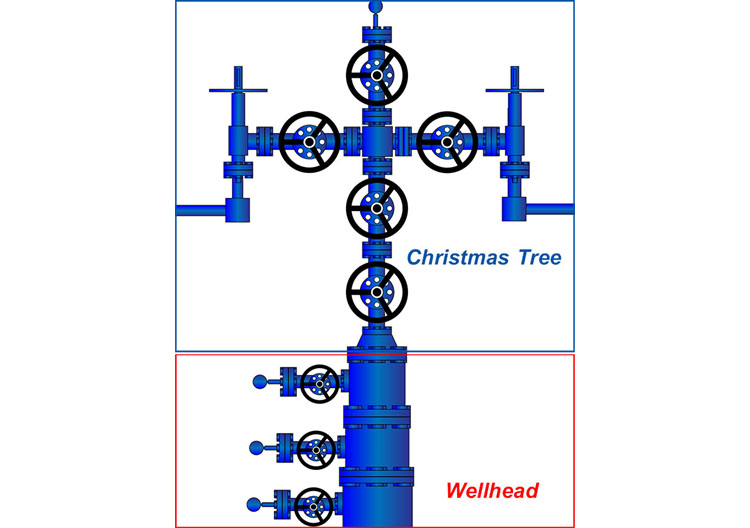

Below are three YouTube videos of jack-up rigs in action. The first YouTube video, Jackup Drilling Rig How Does It Work? (1:36), is an animation showing a jack-up rig being towed to a Well Jacket (the small structure to the right of the video). A well jacket is an offshore structure that typically contains a minimal amount of production equipment, such as, multiple trees/well heads, minimal surface production equipment (a test separator, metering equipment, etc.), and a helideck. A Tree (or Christmas Tree) is the system of valves, chokes, and gages that sits on the top of the well head and is used to direct, control, and shut-in production during the well’s productive life. An illustration of a Christmas Tree and well head is shown in Figure 8.11.

Multiple deviated wells are drilled from the well jacket to various bottom-hole targets and depths. In earlier lessons, we discussed that deviated wells are the most common well orientations used offshore. The clip you are about to watch illustrates why this is the case

Since the well jacket is already in place in this video, we know that the jack-up rig will be drilling a Development Well. This is because the oil company already knows that hydrocarbons are present below and have invested in the well jacket. Also shown in this clip is a supply boat arriving at approximately 1:12 into the video.

In the second YouTube video, Jack-up Rig (0:46), both real footage and animations are included. This video clip seems to be showing two distinct operations. In the first segment (real footage) from 0:00 to 0:12, we see an actual jack-up rig in-place next to two small offshore structures. The structure nearest to the drilling rig is a well jacket as discussed earlier. The second small structure connected by the bridge is a small production platform. These structures are referred to as Bridge-Linked Structures. Since these two structures are present, we know that the jack-up rig is drilling a Development Well.

The animation then begins at 0:12 and appears to show a rig drilling an exploration or appraisal well. We know this because there are no production facilities present in the animation. In fact, the narrator states “… if they hit oil, they will cap the well, jack the rig down, and then tow it to its next location … and a permanent drilling platform will take over pumping the oil.”

I selected this video for two reasons:

- It shows footage of an actual jack-up rig and two offshore structures

- It shows an exploration or appraisal well being drilled from the jack-up rig

I will have a little commentary on some of the narrator’s comments after you watch the video.

I did have a few issues with the narrator in this video. Now that you are an “insider,” did you catch some mistakes made by the narrator? Everything was going well until he stated “… and a permanent drilling platform will take over pumping the oil.” What he should have said was: “… and an offshore facility will take over producing the oil.” As we just learned, a platform produces the oil (this “platform” may be a simple well jacket as we have seen, a large complex Production, Drilling, and Quarters (PDQ) Platform, or a Floating Production, Storage, and Offtake (FPSO) vessel). Regardless, a “permanent drilling platform,” if they existed, would drill, it will not “pump” anything (except for fluids required in drilling, cementing, completion, or workover operations).

Second, the narrator assumed that the discovery well would need to be pumped. As we have seen in earlier lessons, not all reservoirs need artificial lift; many flow naturally. The decision to use artificial lift on this potential discovery will be up to the production engineer and the Asset Team.

The third YouTube video, Haven jack-up test (2:59), is actual footage of a jack-up rig being jacked up, either in a fabrication yard or for periodic maintenance. I selected this video because it shows actual footage of the jack-up and jack-down operations.