The rotary system on a drilling rig is the system that causes the drill bit rotate at the bottom of wellbore. We have discussed some components of the rotary system when we discussed rotary table and top-drive rigs, but we have not yet discussed the entire system.

In the detailed rig schematic (Figure 9.02d), the rotary system is comprised of:

- the Swivel (Item 6)

- the Kelly (Item 8) – the functionality on a top-drive rig is handled by the top-drive

- the Kelly Bushing (Item 9) – the functionality on a top-drive rig is handled by the top-drive

- the Master Bushing (Item 10) – the functionality on a top-drive rig is handled by the top-drive

- the Rotary Table (not shown in Figure 9.02d) – the functionality on a top-drive rig is handled by the top-drive

- the Mousehole (Item 11) – used to connect single joints on a top-drive or rotary table rig

- the Rat Hole (Item 12)

- the Rotary Hose (Item 17)

- the Drill String (not shown in Figure 9.02d)

- the Bottom-Hole Assembly (not shown in Figure 9.02d)

- the Drill Bit (not shown in Figure 9.02d)

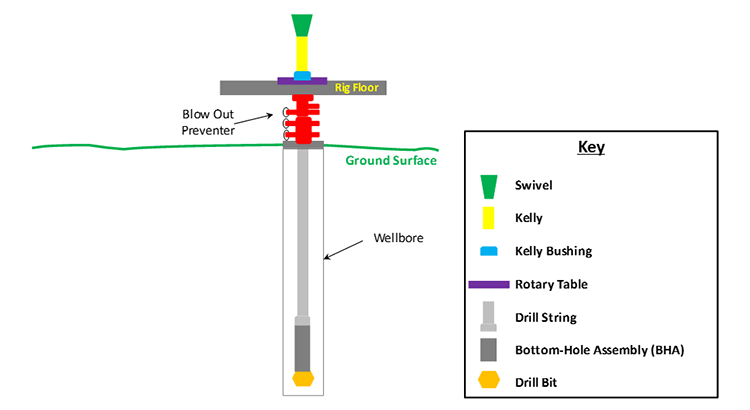

A schematic of the rotary system is shown in Figure 9.07. As we can see in Figure 9.07, the rotary system shares many components with the circulation system. This is because in the rotary system, these components rotate in support of causing the bit to rotate, while in the circulation system, these components act as conduits for the drilling fluid.

In Lesson 8, we saw that the rotary table imparted the torque for the drill string in a conventional rotary table rig, while the top-drive imparted this torque on a top-drive rig. We also saw that drill pipe was added to the drill string one joint at a time on a rotatory table rig, while a top-drive could add multiple joints of drill pipe during one connection operation.

The Bottom-Hole Assembly is comprised of any bottom hole equipment required to drill the current section of the well. A bottom-hole assembly may be as simple as a Drilling Collar. Drill collars are sections of heavy, thick walled pipe used to add weight-on-bit to the drill string. More complicated bottom-hole assemblies may include Jars, downhole directional steering and positioning equipment, logging-while-drilling, and measure-while-drilling equipment.

Jars are mechanical devices that deliver a transfer of kinetic energy to another piece of downhole equipment as the result of an impact. They are typically used to loosen a piece of downhole equipment with an impact (jarring action). You can think of a jar as comparable to a hammer used to loosen two boards that are nailed together by hitting one of the boards in the direction opposite of the head of the nail.

At the end of the drill string and bottom-hole assembly is the drill bit. There are many types of drill bits, but we will focus on two types of drilling bits, the Tri-Cone (or Roller Cone) Bit and Fixed-Cutter Bit. In addition, we will be discussing two variants of the tri-cone bit: the milled-tooth bit and the insert bit. All of these bits can be classified as in the following bullet list:

- tri-cone bits

- milled-tooth bits

- insert bits

- fixed-cutter bits

Tri-cone bits are the most common drilling bits and, historically, have been the workhorse of the drilling industry. As the name implies, tri-cone bits contain three cones, each of which contain cutting teeth.

The two-cone bit (an early version of the tri-cone bit) was invented by Howard Hughes Jr.’s father (Howard Sr.). The tri-cone bit and the formation of the Hughes Tool Co. (now part of Baker-Hughes, a subsidiary of the General Electric Corporation) was the source of the Hughes family wealth. In case you do not know who Howard Hughes Jr. was, he was an award winning pilot in the 1920s and 1930s (holder of several aerial speed records and subject of the movie “The Aviator”), a filmmaker (had controlling interest of RKO Studios and actively produced several notable silent and early “talkie” films), airplane designer (owner of Hughes Aircraft – contractor for the world’s largest wooden airplane, “The Spruce Goose,” with Howard as its only pilot in 1947), and a billionaire by the 1970s and 1980s (back when a billion dollars had some value).

In a milled-tooth bit, the teeth of the bit are machine-milled along with the rest of the cone. The cones of the tri-cone bit, including the teeth, are formed from a single, solid piece of steel. An example of a milled-tooth bit is shown in Figure 9.08.

In this figure, we can see that the teeth of the bit are intrinsic parts of the cones; they are milled from the same piece of steel. These bits, as do all tri-cone bits, drill through the rock by exerting the full weight-on-bit on only a few contact points (the sharpened teeth) between the bit and the rock. This exerts extremely high levels of stress at the contact points causing the rock to fail catastrophically (almost explosively). We will see this in a YouTube video later in the lesson.

One design feature of the tri-cone bit is the interaction of the teeth on the different cones helping to remove any small cuttings or sticky shales/clays (Gumbo Shales) that may get lodged between the teeth and reduce the efficiency of the bit. This phenomenon of cuttings and clays getting lodged between bit teeth is referred to as Bit Balling and results in slower Rates-of-Penetration (ROP) of the drilling process. The self-cleaning action of the teeth in a tri-cone bit is designed to reduce the bit balling.

Milled-tooth tri-cone bits are mainly used for drilling through soft rock formations. This is because, no matter how strong the steel used in the construction of the cone, hard rock can cause excessive wear and degradation of the teeth.

Insert drill bits, on the other hand, are bits in which the teeth are made from materials stronger than the steel used in the cone and are inserted into cone. Example of insert tri-cone bits are shown in Figure 9.09.

While the insert bit shown in Figure 9.09 may superficially look like the milled-tooth bit; careful inspection reveals that the teeth in the insert bit are not milled but are inserted into the cone. Typically, the teeth in an insert bit are made from tungsten-carbide steel (Tungsten Carbide Insert bit or TCI bit) which is a much stronger alloy of steel than the alloys used for the cones. Other design features included on insert bits include the length and the shape of the teeth (short, round-shaped teeth for hard rock formations or long, chisel-shaped teeth soft formations). These designs allow for a range of lithologies for these bits to be used: in hard rock formations that would be inappropriate for milled-tooth bits or in soft rock formations for extended bit-life.

While the insert bit helps to alleviate the issues with tooth-wear, there is an additional source of wear that can shorten the life of a drilling bit. Due to the moving parts associated with a tri-cone (or roller) bit, the bit requires a bearing where the moving parts meet and move past one another. Thus, the wear on the bearings may also shorten the life of the bit.

Fixed cutter bits are bits that do not contain any moving parts. These bits are designed to drill by shearing and scraping the rock formations as opposed to the gouging action used by a tri-cone bit. These bits typically use industrially made diamonds for the teeth and are also known as Polycrystalline Diamond Compact (PDC) bits. Figure 9.10 shows an example of a PDC bit.

The PDC bits are used to drill through very hard rock formations or for extended bit-life drilling. These bits have a large initial cost but because of the hard teeth and lack of any moving parts have a longer bit-life. One recent innovation for PDC bits in geologic basins with many shallow (short-footage) drill sites is the ability to rent the drill bit from the drilling company rather than to purchase it from a tool company. This innovation allows for an operating company to rent the bit and to use it for the footage that they require before relinquishing it to another operating company.

We have discussed that the tri-cone bits and the fixed cutter bits have different drilling actions. Here is a YouTube video, "Drill Bits - Oil and Gas Drilling: From Planning to Production" (3:26), that demonstrates the differences of the explosive, gouging, and crushing action of the tri-cone bit and the scraping action of the fixed cutter bits:

While we're out of the hole the operator also wants to switch to a track hone bit. This style of bid is less aggressive than a PDC and will drill a little slower. Bit selection is very important part of drilling a well so let's go review that now.

While we're out of the hole the operator also wants to switch to a track hone bit. This style of bid is less aggressive than a PDC and will drill a little slower. Bit selection is very important part of drilling a well so let's go review that now.

There are two basic categories of drill bits roller cone bits and fixed cutter bits.

Roller cone bits have cones that roll is the bit turns and projections in the cones gouge, scrape, and crush rock as they roll. Most roller cone bits have three cones and are called tri cone bits.

There are two basic types of roller cone bits millled tooth bits and tungsten carbide insert bits. Milled tooth bits also called steel toothed bits use steel teeth to gouge through rock. Milled toothed bits are best in softer formations and are generally less expensive than other types of bits.

Tungsten carbide insert, or TCI bits, have tungsten carbide treated inserts that gouge, chip, and crush rock. Tungsten carbide is one of the hardest materials known and TCI bits are capable of drilling some of the hardest and most abrasive formations. Tungsten carbide inserts come in a variety of shapes and because of their appearance TCI bits are often called button bits.

Fixed cutter bits do not have moving parts and they work primarily by shearing and scraping through rock. Fixed cutter bits include polycrystalline diamond compact bits, natural diamond bits, and impregnated bits.

Polycrystalline diamond compact, or PDC bits, have tungsten carbide cutters topped with hard caps of diamond composite material. The cutters are angled and arranged to shear channels in the rock. The diamond caps are made by heating and compressing artificial diamond grit with tungsten carbide and other metallic binders. PDC bits come in a variety of designs that can be used for an extensive range of drilling requirements. PDC bits are much more expensive than roller cone bits but can generally penetrate faster and last longer than roller cone bits which saves drilling costs.

Natural diamond bits have industrial grade diamonds set in the bit surface to create an abrasive cutting face. They are primarily used in hard or highly abrasive formations that would be more damaging to other bit types. They are not as effective in softer formations because of their smoother surface profile.

Diamond impregnated bits have PDC cutters protruding straight out of the bit body whereas regular PDC bits have cutters bonded to the outside at an angle to the cutting face. The impregnated design increases cutter stability and the lateral cutting angle keeps cutters sharp as they wear. Diamond impregnated bits are good informations with intermittent layers of soft and hard rock because they can effectively cut through both.

There are many other types of specialty bits including bits for coring, sidetracking, reaming, and other applications.